FAQCommon Problem

Email: [email protected]

Technical Information

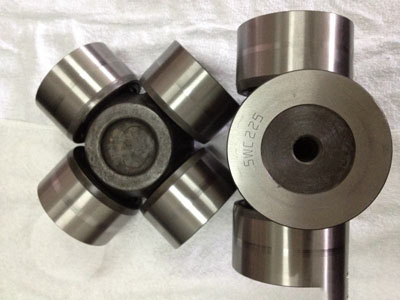

Installation, disassembly and maintenance of universal coupling

How about universal couplinginstallation?

The key component of enterprise mechanical transmission is universal coupling, which is widely used in the connection of equipment reducer and motor.The equipment of universal couplings is a work requiring high precision. If the results of assembly and alignment are not accurate, the vibration value of the equipment will exceed the standard, which will seriously threaten the normal operation of the equipment, especially the high-speed equipment. The shafting process should pay special attention to certain details.

During the installation process, the two halves of the coupling are usually installed on the two shafts to be connected respectively, and then the main machine is aligned, moved, adjusted, and connected, and centered on the main machine rotating shaft based on the main machine.It is judged by measuring the changes of the relative position of the two halves of the coupling, rotating at the same time, in the radial direction and in the axial direction.

In order to give full play to the function of the universal joint, please start installation within the maximum allowable eccentricity range.The installation error in the table is the maximum value when each occurs independently, so it is necessary to consider the allowable value when the compound occurs to be less than half.

When centering, please stick the ruler on the outer periphery of the body, and check with two points separated by about 90°.The use time of the components is greatly affected by the accuracy of the centering.

After installing the universal coupling, be sure to install a safety cover.Otherwise, contact with this product during operation may cause injury.

The installation error of the universal coupling needs to be strictly controlled, and it is usually required that the installation error should not be greater than half of the allowable compensation amount.Pay attention to check the alignment of the two connected shafts after operation, and the relative displacement should not be greater than the allowable compensation amount.Reduce the relative displacement as much as possible to effectively extend the use time of the connected machinery or coupling.

For couplings on high-speed rotating machinery, it is generally required to undergo a dynamic balance test and assemble according to the marks.There are strict restrictions on the weight difference between the connecting bolts, and no replacement is allowed.

For couplings that require lubrication, such as gear couplings, the amount, quality, and sealing condition of the lubricating oil should be checked regularly, and should be supplemented or replaced if necessary.

The installation is often due to incorrect coupling methods and excessive vibration, resulting in abnormal operation, inaccurate center, and overloaded deflection, which will cause damage to the motor, coupling and other mechanical parts. It is recommended to pay attention to the precision balance correction action in the mechanical assembly. Extend the use time of the machine.

universalHow about the couplingDemolition?

The most difficult thing to disassemble a universal coupling is the hub. The hub is an important part to connect the components of the universal coupling. A little carelessness will cause damage to the universal coupling.When disassembling the hub, use a puller that matches the size of the hub for disassembly. Otherwise, it may not be disassembled, or it will slip off if you apply too much force, which may damage the surface of the hub.

At the same time in the process of disassemblyCouplingMake some marks on the common position of each part, as a reference when re-assembling, to avoid not remembering the correct position of each part during installation.And used forCardan shafts for high-speed machines, Its adjacent bolts are weighed, and the mark must be clear and can't be mistaken.Moreover, the bolts are not easy to assemble, and the individual first removes the connecting bolts when disassembling the coupling.At the same time, due to the accumulation of a layer of grease on the thread details, and the external or internal hexagon of the bolt has been slipped and damaged, it will be more difficult to disassemble. For the bolts that have been rusted or with a lot of grease, solvents (such as rust loosener) are often used. Spray the adjacent area between the bolt and the nut so that the solvent soaks into the thread so that it will be easier to disassemble.

Universal coupling maintenance

Routine maintenance of universal coupling XNUMX: Lubricate and replenish the universal coupling regularly.During continuous production of universal joints, the bearing of the cross shaft is lubricated once a month, while the spline shaft is lubricated once every three months.

Daily maintenance of universal couplings XNUMX: When using universal couplings, you need to pay attention to whether the universal couplings can work normally.Whether there is abnormal noise, whether the screws are fastened, whether the bolts are loose, etc., need to be carefully checked.

Routine maintenance of universal coupling XNUMX: During work and operation, it is necessary to observe whether the universal coupling has abnormal radial swing and bearing heating. It is found that these phenomena must be repaired in time.

Routine maintenance of universal coupling four: the universal coupling is regularly inspected and repaired, and some damaged parts are replaced in time.Long-term overload use should be avoided to avoid operation accidents.

- The effect of loose connection bolts 2019-12-11

- Plum blossom coupling size and model 2019-12-09

- The correct way to maintain the coupling of transmission parts 2019-12-09

- Installation, disassembly and maintenance of universal coupling 2019-11-30

- Universal coupling connection and basic principles 2019-10-09