FAQCommon Problem

Email: [email protected]

Technical Information

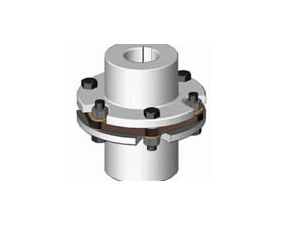

Installation and principle of diaphragm coupling

Diaphragm couplingIt consists of several groups of diaphragms (stainless steel thin plates) that are alternately connected with the two halves of the coupling with bolts. Each group of diaphragms is composed of several stacked ones. The diaphragms are divided into connecting rod type and

Whole pieces of different shapes formula.The diaphragm coupling depends on the elastic of the diaphragm It is a high-performance flexible coupling with strong metal components to compensate for the relative displacement of the connected two shafts

Device, No lubrication, compact structure and strength High, long service life, no rotation gap, not affected by temperature and oil pollution, It has the characteristics of acid resistance, alkali resistance and corrosion resistance

Point, suitable For shafting transmission in high temperature, high speed, and corrosive environment

XNUMX. Installation of diaphragm coupling

1. Wipe clean the dust and dirt on the surface of the installation shaft, and apply a thin layer of engine oil or lubricant.

2. Clean the inner hole of the Lingsi coupling, and apply oil or lubricant.

3.Insert the Lingsi coupling into the mounting shaft; if the aperture is too tight, be careful not to hit the installation with a hammer or hard metal.

4. After the positioning is completed, first use a torque wrench (the specified tightening torque 1/4) to gently tighten the screws in the diagonal direction.

5. Increase the strength (1/2 of the specified tightening torque) and repeat the fourth step.

6.Tighten the tightening torque according to the specified tightening torque.

7.Finally, tighten the fixing screws in the circumferential direction.

8.When disassembling, please proceed with the device completely stopped; loosen the locking screws one by one.

XNUMX. Matters needing attention in installation of diaphragm coupling

①. Products with diaphragms have edges and may cause injuries. It is recommended to wear thick gloves when installing.

②. Please install a protective cover and other devices around the coupling to ensure safety.

③. When the shaft center deviation exceeds the allowable value during installation, the coupling may be deformed, resulting in damage or shortened service life.

④. The allowable axis deviation of the Lingsi diaphragm coupling includes radial, angular, and axial deviation. When installing, please adjust to ensure that the axis deviation is within the allowable range of the corresponding product catalog.

⑤ When multiple deviations appear at the same time, the corresponding allowable value should be halved.

⑥. In order to extend the service life of the coupling, it is recommended to set the shaft deviation within 1/3 of the allowable value.

⑦. Tighten the screws after inserting the mounting shaft, otherwise the coupling will be deformed. When tightening the screws, please use a torque wrench, do not use screws other than the accessories for installation.

⑧. If an abnormal sound occurs during operation, please stop the operation immediately and check the installation accuracy, Check the looseness of the screws separately. It is recommended to apply adhesive on the outer surface of the screws after installation and commissioning to increase the protection performance.

Third, the principle of diaphragm coupling

Its working principle is: the torque from the driving shaft(Motor side)The flange is transmitted to the short section of the middle section through bolts and diaphragm groups, and then from the middle section to the slave section through the bolt diaphragm group.

Moving shaft(Steam pump side). In addition to the diaphragm coupling can transmit In addition to torque, the elastic deformation of the diaphragm can also be used to compensate for misalignment under various working conditions.Diaphragm coupling

The damage of the device is mostly caused by the breakage of the diaphragm Caused by damage, therefore, as long as the diaphragm is damaged, it is considered that the coupling has been lost. Effective, so the diaphragm is the key part of the research

Pieces. Diaphragm couplingIt is an all-metal interference coupling, It is realized by elastic deformation of thin high-strength alloy steel or stainless steel sheetDiaphragmCoupling

DeviceDisturbance Sexual transmission Dynamic, there is greater disturbance in the axial and angular directions, and can compensate for the two axes3Directions (Axial, radial, angular)Relative displacement, and have Vibration absorption and reduction

Vibration effect, The coupling can absorb the misalignment and impact of the drive shafts on both sides, especially Not suitable for high-speed, heavy-duty Occasions.Its structure is simple, loading and unloading Flight,

No lubrication and Maintenance, it has the characteristics of acid and heat resistance, so it is widely used in aviation, shipbuilding, petrochemical industry, machinery manufacturing and other fields

- The effect of loose connection bolts 2019-12-11

- Plum blossom coupling size and model 2019-12-09

- The correct way to maintain the coupling of transmission parts 2019-12-09

- Installation, disassembly and maintenance of universal coupling 2019-11-30

- Universal coupling connection and basic principles 2019-10-09