FAQCommon Problem

Email: [email protected]

Technical Information

The basic principle of diaphragm coupling and three points of installation

XNUMX. What is a diaphragm coupling

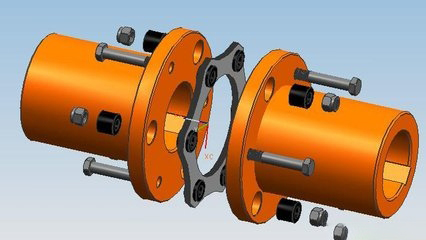

The diaphragm coupling consists of several groups of diaphragms (stainless steel sheet) which are alternately connected with the two halves of the coupling with bolts. Each group of diaphragms is made up of several pieces. The diaphragms are divided into connecting rods and different shapes. Sliced.The diaphragm coupling relies on the elastic deformation of the diaphragm to compensate for the relative displacement of the two shafts connected. It is a high-performance flexible coupling with strong metal components, no lubrication, compact structure, high strength and long service life. , No rotation gap, not affected by temperature and oil pollution, with acid and alkali resistance and corrosion resistance, suitable for high temperature, high speed, and corrosive mediaShafting transmission in working environment.

two,Principle of diaphragm coupling

The diaphragm coupling is composed of at least one diaphragm and two shaft sleeves.The diaphragm is fastened to the shaft sleeve with a pin and generally does not loosen or cause backlash between the diaphragm and the shaft sleeve.Some manufacturers provide two diaphragms, and others provide three diaphragms, with one or two rigid elements in the middle, and the two sides are connected to the shaft sleeve.The difference between the single diaphragm coupling and the double diaphragm coupling is the ability to handle various deviations. In view of the complex bending of the diaphragm, the single diaphragm coupling is not suitable for eccentricity.The double diaphragm coupling can bend in different directions at the same time to compensate for eccentricity.

Diaphragm coupling is mainly composed of stainless steel sheet metal (steel sheet), half coupling, intermediate sleeve, compression element, bolt, lock nut, limit washer, etc.Torque is input from the half coupling of the active end, and the torque is transmitted to the front flexible steel plate group through high-strength bolts arranged at intervals along the circumference, and then from the flexible steel plate group to the intermediate sleeve through the high-strength bolts, and is also transmitted by the flexible steel plate group through the high-strength bolts. The rear end of the flexible steel sheet group, high-strength bolts and driven half coupling output.Steel sheet components are flexibleDiaphragm couplingThe key component of the, it is composed of a certain number of thin elastic stainless steel laminated, through which to transmit torque and eliminate the offset from multiple directions.The thickness of the steel sheet is generally selected according to the size of the torque and the different working conditions, generally 0.35 ~ 1.20mm, and its shapes include ring type, connecting rod type, waist type and so on.

three,Diaphragm coupling installation

1. Before installation, first check whether the prime mover and the working machine are concentric, whether there are wrapping paper and scratches on the surfaces of the two shafts, whether there are debris in the inner holes of the two half couplings of the coupling, and whether there are any edges of the inner holes. If there are bruises, the shaft and half coupling should be cleaned up, and the bruises should be treated with a fine file.Then check whether the inner hole diameter and length of the two half couplings are consistent with the diameter and shaft elongation of the prime mover and working machine.In general selection, it is better to make the length of the prime mover and the working machine end half-coupling less than 10-30mm of shaft elongation.

2.In order to facilitate the installation, it is best to put the two half couplings in the 120150 thermal insulation box or oil tank for preheating, so that the inner hole size increases and it is easy to install.After installation, ensure that the shaft head cannot protrude from the end face of the half coupling, and it is better to be flush.Detect the distance between the two halves of the coupling: 34 points of readings measured along the two inner sides of the flange of the half coupling are averaged, and the sum of the measured dimensions of the extended section and the two diaphragm sets is controlled by the error. Within the range of 0-0.4mm.

3.找正:用百分表检测两半联轴节法兰盘端面和外圆跳动,当法兰盘外圆小于250mm时跳动值应不大于0.05mm;当法兰盘外圆大于250mm时,跳动值应不大于0.08

installationElastic diaphragm couplingThe 8 points to note are as follows:

①. The product with diaphragm has edges and may cause injury. It is recommended to wear thick gloves when installing.

②. Please install a protective cover and other devices around the coupling to ensure safety.

③. When the shaft center deviation exceeds the allowable value during installation, the coupling may be deformed, resulting in damage or shortened service life.

④. The allowable axis deviation of the coupling includes radial, angular and axial deviations.When installing, please make adjustments to ensure that the axis deviation is within the allowable range of the corresponding product catalog.

⑤. When multiple deviations appear at the same time, the corresponding allowable value should be halved.

⑥. In order to prolong the service life of the coupling, it is recommended to set the shaft deviation within 1/3 of the allowable value.

⑦. Tighten the screws after inserting the mounting shaft, otherwise the coupling will be deformed. When tightening the screws, please use a torque wrench, do not use screws other than accessories for installation.

⑧. If abnormal noise occurs during operation, please stop the operation immediately and check the installation accuracy and screw loosening. It is recommended to apply adhesive on the outer surface of the screw after installation and debugging to increase the protection performance.

- The effect of loose connection bolts 2019-12-11

- Plum blossom coupling size and model 2019-12-09

- The correct way to maintain the coupling of transmission parts 2019-12-09

- Installation, disassembly and maintenance of universal coupling 2019-11-30

- Universal coupling connection and basic principles 2019-10-09