Product displayProduct Display

- Coupling

- Small flexible coupling

- Pulley

- gear

- rack

- Sprocket

- Spiral bevel gear

- Bevel gear

- Worm Gear

- Expansion coupling sleeve

- Torque limiter

- Timing belt

- Pulley

- Cone sleeve embedded pulley

Email: [email protected]

Coupling

ML plum coupling

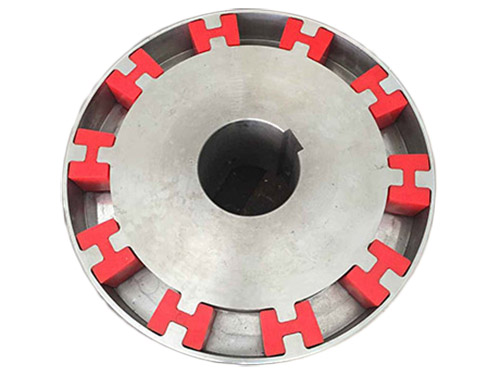

MLPlum couplingIt is a widely used coupling, also called a claw coupling, which is composed of two metal claw discs and an elastic body.The two metal claws are generally made of No. 45 steel, but aluminum alloys are also useful when load sensitivity is required.

ML plum blossom coupling is composed of two half-couplings with the same shape of the claws and elastic elements. The plum blossom-shaped elastic element is placed between the two halves of the coupling claws to realize the connection of the two halves of the coupling. .Basic quincunx elastic coupling. When changing the elastic element, the two halves of the coupling need to move along the axial direction to achieve the purpose of changing the elastic element.

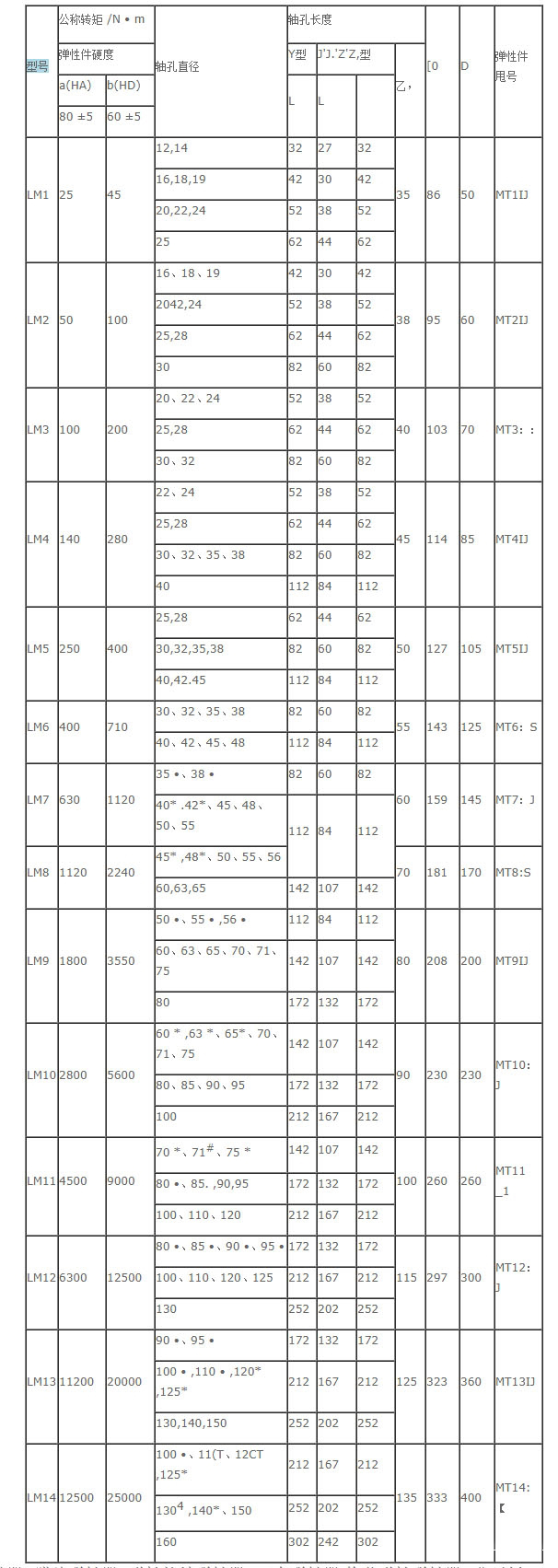

ML梅花联轴器主要适用于起动频繁、正反转、中高速、中等扭矩和要求高可靠性的工作场合,例如:冶金、矿山、石油、化工、起重、运输、轻工、纺织、水泵、风机等。公称转矩为25~12500N.m,许用转速为15300~1900r/min,轴孔直径为12~160mm。

The ML plum coupling is processed by machining methods such as turning, milling, and broaching, and then undergoes overall heat treatment.In order to ensure sufficient mechanical strength, there is also a claw plate on the market that is a casting, which can be produced in large quantities and eliminates processing losses.So the price is much lower than machining.But the performance of the casting is not very good.Do not use it in some important occasions.And the claws of the casting are prone to tooth punching (claws falling off) at high speed or high load.

MRefer to the table for dimensions of L plum coupling,

Correct installation of plum coupling:

1) Wipe clean the dust and dirt on the surface of the installation shaft, and apply a thin layer of engine oil or lubricant.

2) Clean the inner hole of the plum blossom coupling and wipe it with oil or lubricant.

3) Insert the plum blossom coupling into the installation shaft; if the hole diameter is too tight, be careful not to hit the installation with a hammer or hard metal.

4) After the positioning is completed, first use a torque wrench (the specified tightening torque 1/4) to gently tighten the screws in the diagonal direction.

5) Increase the strength (1/2 of the specified tightening torque) and repeat the fourth step.

6) Tighten the tightening torque according to the specified tightening torque.

7) Finally, tighten the fixing screws in the circumferential direction.

H type coupling

H type coupling JMI diaphragm coupling

JMI diaphragm coupling GICL drum gear coupling

GICL drum gear coupling