Product Description

CHAIN COUPLING

Chain couplings are used for textile, agricultural machinery, lifting transporation, engineering, mining, light industry, chemical industry and other mechanical transmission shaft, suitable for high temperature, wet and dusty conditions, but not suitable for high-speed, sevious impact loading and axial force transmission occasions.

. Production Description

More Couplings

Other transmission products:

Roller Chain, Sprocket, V Pulley, Timing Pulley, Coupling, Gear Rack, Ball Bearing, Pillow Block Bearing

Packing and Delivery

FAQ

1. Can I get any sample ?

Samples are free to be available, if there is any in stock. But you have to absorb the relative courier fee.

2. How long is the delivery time for the production?

Production lead time is 30-60 days for the production.

3. What’s your advantage?

Competitive price, good quality, high-experience engineers abailable

What materials are typically used in manufacturing spider couplings and why?

Spider couplings are constructed using a combination of materials to achieve durability, flexibility, and efficient torque transmission. The choice of materials depends on factors such as application requirements, environmental conditions, and the desired balance between strength and flexibility. Common materials used in manufacturing spider couplings include:

- Aluminum: Aluminum is lightweight and corrosion-resistant, making it suitable for applications where weight reduction is important. It offers good mechanical properties and can be used in various industries.

- Steel: Steel provides excellent strength and durability. It’s often used in heavy-duty applications where high torque transmission is required. Surface treatments can enhance corrosion resistance.

- Stainless Steel: Stainless steel offers corrosion resistance in aggressive environments. It’s commonly used in industries such as food processing, pharmaceuticals, and chemical processing.

- Cast Iron: Cast iron is known for its high compressive strength and wear resistance. It’s suitable for applications requiring robust construction and can handle high torque loads.

- Plastic/Polymer: Certain polymers and plastics, such as polyurethane or nylon, are used for the elastomeric spider element. These materials provide flexibility, vibration dampening, and misalignment compensation.

The choice of materials depends on the specific requirements of the application. For example, aluminum or stainless steel may be chosen for industries requiring corrosion resistance, while steel or cast iron may be selected for heavy-duty applications. The elastomeric spider is typically made from a durable polymer to ensure flexibility and effective torque transmission while accommodating misalignment. Overall, selecting the right materials ensures that spider couplings can withstand the demands of the intended application and provide reliable performance over their lifespan.

Are there any specific maintenance practices for ensuring the longevity of spider couplings?

Yes, implementing proper maintenance practices is crucial for ensuring the longevity and optimal performance of spider couplings. Here are some specific maintenance practices to consider:

- Regular Inspections: Conduct routine visual inspections of the coupling to identify any signs of wear, damage, or misalignment. Regular inspections allow you to detect issues early and address them before they escalate.

- Lubrication: Follow the manufacturer’s recommendations for lubrication intervals and use the appropriate lubricant. Proper lubrication reduces friction, prevents excessive wear, and maintains coupling efficiency.

- Alignment Checks: Ensure that the shafts connected by the coupling are properly aligned. Misalignment can accelerate wear and compromise coupling performance. Regular alignment checks are essential, especially after maintenance or changes in operating conditions.

- Torque Checks: Periodically check the torque values of fasteners such as bolts, nuts, and screws that secure the coupling components. Proper torque ensures the coupling remains securely fastened.

- Temperature Monitoring: Monitor the operating temperature of the coupling during normal operation. Abnormally high temperatures can indicate excessive friction and potential issues with the coupling.

- Environmental Considerations: If the machinery is operating in harsh or corrosive environments, take appropriate measures to protect the coupling from contaminants, chemicals, and moisture.

- Replacement of Elastomeric Spider: The elastomeric spider is a critical component of the coupling. Replace it if you notice signs of wear, cracks, tears, or deformation. Follow the manufacturer’s recommended replacement intervals.

- Documentation: Maintain records of maintenance activities, inspections, and any repairs performed on the coupling. This documentation helps track the history of the coupling and informs future maintenance decisions.

- Training and Education: Ensure that maintenance personnel are trained in proper coupling maintenance practices. This includes handling, installation, and lubrication procedures.

By adhering to these maintenance practices, you can extend the lifespan of spider couplings, reduce the likelihood of unexpected failures, and ensure the continued reliability of machinery systems.

How do you properly install and maintain a spider coupling in machinery?

Installation:

Proper installation of a spider coupling is essential to ensure its optimal performance and longevity. Here are the steps for installing a spider coupling:

- Ensure Safety: Before starting any installation, make sure the machinery is properly shut down and all energy sources are disconnected.

- Inspect Components: Check the hubs, elastomeric spider, and shafts for any damage or debris. Ensure that the components match the correct specifications.

- Align Shafts: Align the shafts to minimize initial misalignment before inserting the elastomeric spider.

- Insert Spider: Place the elastomeric spider into one of the hubs, ensuring that the lobes or fins are correctly aligned with the grooves in the hub.

- Align Second Hub: Carefully align the second hub with the first one, making sure the spider lobes fit into the grooves of both hubs.

- Press Hubs Together: Gently press the hubs together until they meet. Avoid using excessive force, as this could damage the elastomeric spider.

- Check Alignment: After installation, check the alignment of the shafts and the coupling. Misalignment should not exceed the manufacturer’s recommended limits.

- Tighten Fasteners: Tighten the fasteners on the hubs according to the manufacturer’s torque specifications. Use a torque wrench to ensure proper tightening.

- Verify Clearance: Check for proper clearance between the coupling and surrounding components to prevent interference during operation.

- Run System: Start the machinery and monitor the coupling for any unusual vibrations or noise. Make any necessary adjustments if issues are detected.

Maintenance:

Maintaining a spider coupling is important to ensure its continued performance and prevent premature failure. Here are some maintenance tips:

- Regular Inspection: Periodically inspect the spider coupling for signs of wear, damage, or deterioration. Look for cracks, tears, or other abnormalities in the elastomeric spider.

- Clean Environment: Keep the coupling and surrounding area clean from dirt, debris, and contaminants that could impact its performance.

- Lubrication: Spider couplings are self-lubricating due to the elastomeric material. Avoid using additional lubricants, as they can deteriorate the elastomeric properties.

- Temperature Consideration: Be aware of the temperature range specified by the manufacturer for the elastomeric material. Extreme temperatures can affect the performance and lifespan of the coupling.

- Replace Worn Parts: If the elastomeric spider shows signs of wear, replace it with a new one from the manufacturer. Do not continue using a worn or damaged spider.

- Monitor Vibrations: Regularly monitor the machinery for unusual vibrations or noise, as these can indicate issues with the coupling. Address any problems promptly.

- Follow Manufacturer Guidelines: Adhere to the manufacturer’s recommended maintenance schedule and guidelines for the specific spider coupling model.

Proper installation and regular maintenance contribute to the reliable and efficient operation of a spider coupling in machinery.

editor by CX 2023-11-30

China Quality Guaranteed Stainless Steel Chain Sprocket Chain Coupling with ISO Certification coefficient of coupling

Solution Description

ZHangZhoug CZPT Machinery Co., Ltd

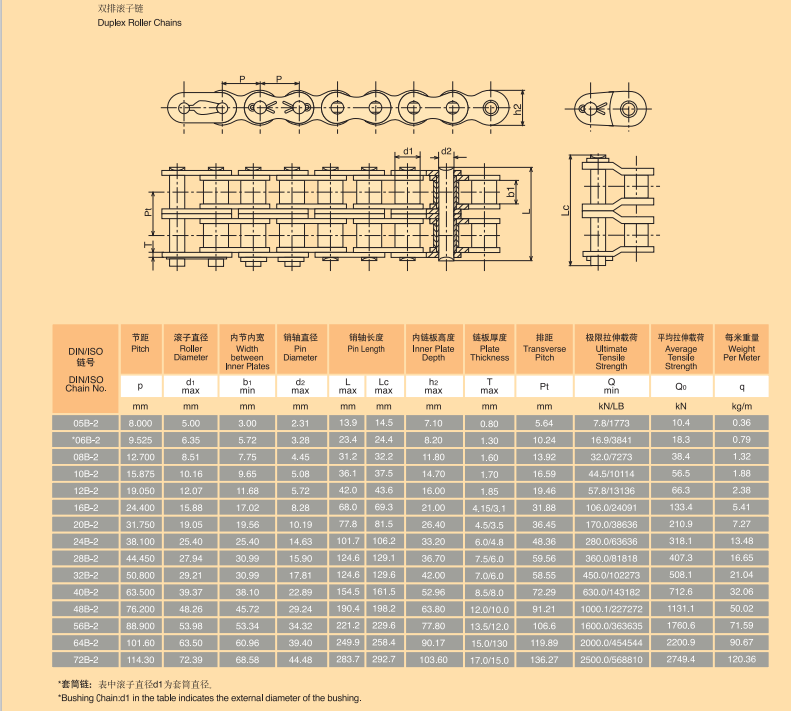

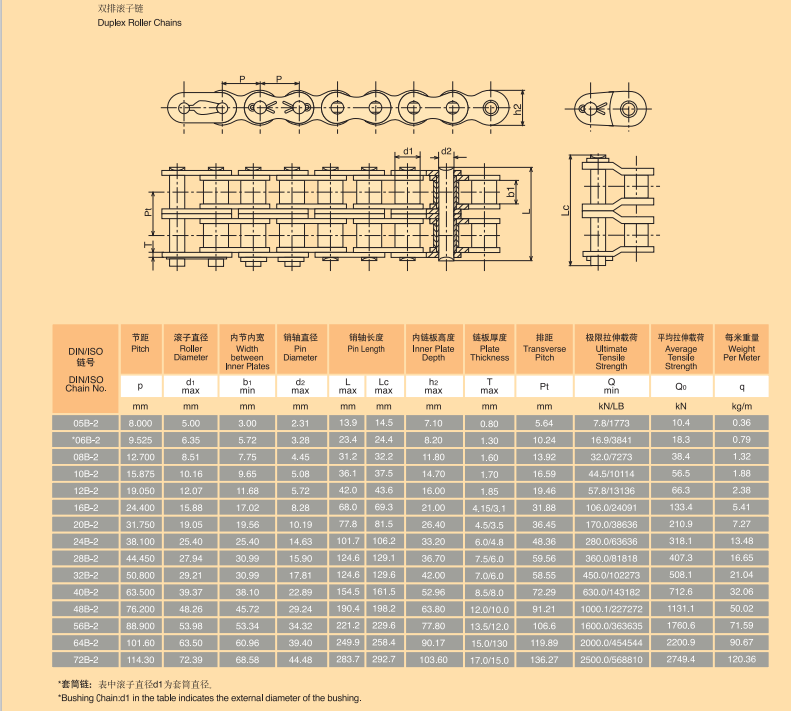

(DIN/ANSI/JIS Standard or manufactured to drawing)

Product Description:

ZHangZhoug CZPT Machinery Co., Ltd. Is the vice chairman of chain Transmission Department of China Machinery Basic elements Market Association and a member of China chain Transmission Standardization Technical Committee.

Started in 1954, largely engaged in sprocket, equipment, timing belt pulley, coupling generation and sales, It is a large sprocket production company in China, and it is also 1 of the greatest common sprocket manufacturers in the globe at existing. The solution construction of the business has been developed from the single pattern of normal sprocket to non-regular transmission areas. Merchandise are largely sold in North America, South The us, Europe, Africa and Japan, South Korea, the Center East, Russia and Southeast Asia and other international locations and regions, sales community all more than the planet.

The business has handed ISO 9002 high quality assurance system certification for the 1st time in 1999, ISO9001: 2000 top quality administration system certification in 2003, ISO/TS16949 high quality management method certification for the very first time in 2009, ISO14001: 2004 environmental management method certification for the initial time in 2571, ISO14001: 2015 environmental management program certification for 2017, and ISO9001: 2015 and IATF16949: 2016 high quality management method certification for 2018. It lays a CZPT foundation for perfecting the inner administration of the business and opening up the exterior industry.

The business adheres to the enterprise philosophy of “High quality is lifestyle, technological innovation is physique, supply is moral, amount is credit, support is kindred, cost is lifetime”, employing “innovation-pushed, twinning integration” upgrading technique, selling chain transmission goods to excellence, and creating each and every hard work to produce “harmonious cenfit, excellent quality cenfit, hundred years of cenfit”

|

/ Piece | |

200 Pieces (Min. Order) |

###

| Standard Or Nonstandard: | Standard |

|---|---|

| Application: | Motor, Machinery, Agricultural Machinery, Car |

| Hardness: | Soft Tooth Surface |

| Manufacturing Method: | Rolling Gear |

| Toothed Portion Shape: | Spur Gear |

| Material: | C45 |

###

| Customization: |

|---|

|

/ Piece | |

200 Pieces (Min. Order) |

###

| Standard Or Nonstandard: | Standard |

|---|---|

| Application: | Motor, Machinery, Agricultural Machinery, Car |

| Hardness: | Soft Tooth Surface |

| Manufacturing Method: | Rolling Gear |

| Toothed Portion Shape: | Spur Gear |

| Material: | C45 |

###

| Customization: |

|---|

Programming With Couplings

A coupling is a mechanical device that connects two shafts together and transmits power. Its purpose is to join rotating equipment and allows some degree of end-movement or misalignment. There are many different types of couplings. It’s important to choose the right one for your application.

Mechanical connection between two shafts

There are many ways to achieve mechanical connection between two shafts, including the use of a coupling. One common type is the beam coupling, which is also known as a helical coupling. It is used for transmission of torque between two shafts. This type of connection accommodates axial, parallel and angular misalignments.

The hubs and shafts of a worm gear are connected together by a coupling. This mechanical connection allows one shaft to turn another without causing a mechanical failure. This type of coupling is made from sliding or rubbing parts to transfer torque. However, the coupling is not designed to withstand jerks, so it isn’t suitable for high-speed applications.

The use of a coupling is common in machinery and equipment. It helps transmit power from one drive shaft to the other, while adding mechanical flexibility. It is also useful for reducing the impact and vibration caused by misalignment. It also protects the drive shaft components from wear and tear.

A double-hook coupling can be used to provide a uniform angular velocity at the driven shaft. Another example is a double-jointed coupling. A double-jointed coupling can be used to connect shafts that are not directly intersecting. The double-jointed yoke can be used for the same purpose.

A shaft coupling is a device that maintains a strong mechanical connection between two shafts. It transfers motion from one shaft to another, at all loads and misalignments. Unlike a conventional linkage, a shaft coupling isn’t designed to allow relative motion between the two shafts. Couplings often serve several purposes in a machine, but their primary use is torque and power transmission.

Functions that control the flow of another function

One of the simplest programming constructs is a function that controls the flow of another function. A function can take an argument and return a different value, but it must be ready to return before it can pass that value to another function. To do this, you can use the goto statement and the if statement. Another way to control flow is to use a conditional statement.

Criteria for selecting a coupling

There are several important factors to consider when choosing the right coupling. One of the most important factors is coupling stiffness, which depends on the material used and the shape. The stiffness of a coupling determines its ability to resist elastic deformation. A stiff coupling is desirable for certain types of applications, but it’s undesirable for others. Stiffness can reduce the performance of a system if there’s too much inertia. To avoid this, ensure that the coupling you choose is within the recommended limits.

The size of a coupling is also important. Different coupling types can accommodate different shaft sizes and shapes. Some couplings have special features, such as braking and shear pin protection. When choosing a coupling, you should also consider the type of driven equipment. If you need to connect a high-torque motor, for example, you’ll want to choose a gear coupling. Likewise, a high-speed machine may require a disc coupling.

Another factor to consider when selecting a coupling is the torque rating. Despite its importance, it’s often underestimated. The torque rating is defined as the torque of the coupling divided by its OD. In some cases, torque may fluctuate during a cycle, requiring a coupling with a higher torque rating.

Torsionally flexible couplings are also important to consider. Their design should be able to withstand the torque required during operation, as well as the required speed. The coupling should also have a high degree of torsional stiffness, as well as damping. Furthermore, a damping coupling can reduce the energy wasted through vibration.

The sizing of a coupling is also determined by the torque. Many engineers use torque to select the correct coupling size, but they also take into consideration torsional flexibility and torsional stiffness. For example, a shaft may be able to handle large torque without damaging the coupling, while a disk may be unable to handle large amounts of torque.

Besides torque, another important consideration in coupling selection is the cost. While a coupling may be cheaper, it may be less reliable or easier to maintain. Couplings that are difficult to service may not last as long. They may also require frequent maintenance. If that’s the case, consider purchasing a coupling with a low service factor.

There are many different types of couplings. Some require additional lubrication throughout their lifetime, while others are 100% lubrication-free. An example of a 100% lubrication-free coupling is the RBI flexible coupling from CZPT. This type of coupling can significantly reduce your total cost of ownership.

In addition to the above-mentioned benefits, elastomeric couplings are low-cost and need little maintenance. While they are often cheaper than metallic couplings, they also have excellent shock absorption and vibration dampening properties. However, they are susceptible to high temperatures. Also, they are difficult to balance as an assembly, and have limited overload torque capacity.

editor by CX 2023-03-29

China Chain and sprocket factory : 3mm pizza hut in Namangan Uzbekistan Inch Stainless Steel Ball for Bearing Chain with ce certificate top quality low price

We – EPG Team the most significant Chain and agricultural gearbox manufacturing facility in China with 5 distinct branches. For more details: Cellular/whatsapp/telegram/Kakao us at: 0086-13083988828

If you are fascinated in any of our items or would like to discuss a prospective order, make sure you truly feel free of charge to speak to us. No we supply one particular-end solution for the acquire of mechanical chain,energy transmission components and pto shaft, agricultural gearboxes items in China. other range of chains can defeat EPG for range. Apart from typical roller chains of all types and measurements, roller chains with attachments and double pitch roller chains, we also offer specific chains such as grip chains, accumulation chains, elastomeric profile chains, leaf chains, bushed conveyor chains, hollow pin chains and many other types. Maintenance-free or corrosion-evidence chains are available for particular purposes. Our pin oven chains and tube conveyor chains empower a broad range of options for the successful creation and ideal conveying of cans and tubes. Find out a lot more about our item EPT chains, both regular and non-standard, are created of: ○ Large top quality steels: dimensions and tailored chemical composition for the different chain areas ○ The most efficient manufacturing processes: • Unique technique for the production of bushes improving the chain wear resistance ( EPT know-how) • Plates produced by multi-phase processing instruments guaranteeing a normal pitch ( EPT technology) ○ Adequate mechanical and heat therapies of chain components: • Shot peening • Surface finishing • Scenario hardening, carbonitriding, quenching, tempering … • EPT®treatment • Freezing treatment method • Corrosion protection coatings (GEOMET, zinc, nickel plating, …) Chrome metal/bearing metal ball

| Chrome steel ball/bearing metal ball | ||||||||||

| 1. Substance | AISI 52100/ 100Cr6/ 100C6/ SUJ2/ Wks 1.3505 | |||||||||

| 2. Measurement Range | 0.6mm-180mm | |||||||||

| 3. Quality | G10-1000 | |||||||||

| 4. Hardness | 58-65 HRC | |||||||||

| 5. Attribute | (a)Primarily utilised in bearings (b)Great hardness (c)Great resistance to deformation with excellent wear resistance (d)Lower corrosion |

|||||||||

| 6. Magnetic | Yes | |||||||||

| 7. Software | Ball bearings, bicycles, Auto: +86~13083988828 sector | |||||||||

| 8. Chemical composition | ||||||||||

| C% | Si% | Mn% | S% | P% | Cr% | Mo% | Cu% | Al% | O% | |

| min. | .ninety three | .fifteen | .25 | — | — | 1.35 | — | — | — | — |

| max. | one.05 | .35 | .forty five | .015 | .571 | 1.sixty five | .1 | .3 | .05 | .0015 |

| 9.Packing | StHangZhourd: 10kg or 20kg for each carton,1 ton for every pallet or as customer necessary | |||||||||

| 10.Conditioning | dry or oiled | |||||||||

| 11.Shipping and delivery time | Stock inside of a short time or 35 days. | |||||||||

Merchandise details:

This is an oil hardened steel, which is universally utilised by the ball and roller bearing sector. This metal has

quite great hardness, quite great physical qualities and outstanding wear resistance.

Gear&Process

| Manufacture method of steel balls | ||||

| Step 1 Heading | Bal EPT blanks are chilly headed from rol EPT of wire. | |||

| Step 2 Flashing | Rolling bal EPT amongst two tough alloy plates to gets rid of the slight band and small protrusions. |

|||

| Step 3 Heat handle | Heating bal EPT to a high temperature in furnace and quenching bal EPT in a liquid tub. | |||

| Step 4 Rough grind | Rolling bal EPT in between the face of a fixed iron plate and a very tough fire-grit grinding wheel. Then rolled the hardened ground bal EPT in between two ca EPT iron plates. | |||

| Step 5 Cleaning | The final creation procedure cleans the finished bal EPT and adds a shiny luster. | |||

| Step 6 Final Inspection |

Bal EPT are gauged, visually inspected and subjected to EPT high quality assessments to insure every single customer’s technical specs are reached. |

|||

| Step 7 Packaging | The bal EPT are packaged in accordance with customer specifications for shipping and delivery. | |||

Packaging and Delivery

Packaging

Type 1 :Plastic bag + box + carton + wooden pallet

Variety 2 :Plastic bag + carton + wooden pallet

Type 3 :Our package :Export cartons, metal drums, wooden pallets

Transport:

1. EXPRESS

2. AIR

3. SEA

Certification:

one. ISO 3290

two. BV

3. SGS

4. TS16949

Manufacturing facility

one. Recognized because 12 months 1986, much more than 27 a long time expertise and specialized in steel bal EPT manufacturer and ball related products.

two. Higher precision devices and technological staffs.

three. Supply the excellent high quality provider and item with short shipping occasions.

CERTIFICATIONS

ISO, TS16994, BV, SGS

SEVERICE

1. All the inquiries will be reply in 24 several hours

2. For the metal ball, please kindly let us know the measurement, materials, grade and quantity.

3. For the bearing, remember to kindly let us know bearing kind, materials, Accuracy Quality/Course, and amount.

FAQ

1. What variety of steel bal EPT can source by HUARI Metal BA EPT CO., LTD. ?

| Substance | Carbon, Chrome, Stainless, Aluminium, Copper, Brass and so on. |

| Measurement range | .8mm-150mm |

| Grade | G10-a thousand |

| Packing | StHangZhourd or as customer needed |

| Shipping and delivery | Inventory inside of a short time or 35 days |

2. Some EPT query?

Q1. — If ‘I’ want modest amount and fa EPT shipping and delivery. Which way of delivery is suggested ?

A1. — By express.

Q2. — How many amount will be packed in one particular carton or one particular pallet ?

A2. — 20 to 25kg for every carton,1 ton for each wooden pallet.

Q3. — What’s the direct time ?

A3. — If in stocks,2-5daysor ,it will consider twenty-35days,depend on the quantity.

Q4. –Which variety of payment will be acknowledged ?

A4. — T/T, We EPT Union, L/C, …

3. How to location an buy?

| Inquiry |

Quotation | Order | Deposit Payment | Generation | Packing | Equilibrium Payment | Delivery | Done |

Why decide on us

1.a hundred% ensure for our high quality.

two.Our products have BV and ISO certification.

three.Expert producer with 30years knowledge.

4.Our steel bal EPT and bearings are sold all more than the world.

5.Have sophisticated manufacturing products, to guarantee that every step excelsior.

6.Tseting tools to ensure that every steel ball is inspected under serious top quality stHangZhourd.

7.Robust packing make sure the merchandise delivered to customers in good condition.

8.Specialist export revenue and provider group. To make certain that your acquire below relaxed way.

Make contact with us make sure you

Chris

Cell: +86~13083988828:-519-81181030*610 fax:-519-81181083

Cell: +86~13083988828:-1565-1222-707

World wide web:

World wide web:

Any futher query, remember to do get in touch with us whenever.

The use of first equipment manufacturer’s (OEM) element numbers or emblems , e.g. CASE® and John Deere® are for reference purposes only and for indicating item use and compatibility. Our organization and the outlined substitute elements contained herein are not sponsored, accepted, or manufactured by the OEM.

Steel made in China – replacement parts – in Cucuta Colombia Stock Bore Sprocket Power Transmission Professional Agriculture Chain with ce certificate top quality low price

We – EPG Group the bigge EPT Chain and agricultural gearbox factory in China with 5 diverse branches. For much more details: Cellular/whatsapp/telegram/Kakao us at: 0086~13083988828 13858117778 0571 88828

| About us

Our firm was established in 1998, the company largely produces motor bases, motor guidebook rails, non-standard sheet metallic welding elements, stamping components and EPT goods, eighty% for export. The organization has sophisticated specialized tools, scientific pc management model, robust technological power and production expertise. |

Product Description

one. American Regular, European Regular, Japanese Regular

2. Pilot bore, finished bore, taper bore and unique bore offered

three. EPT surface area and higher precision

4. Advanced warmth remedy and floor treatment method crafts

five. Greater top quality and aggressive price tag.

six. Materials C45(1045), low carbon steel, 40Cr, 20CrMnTi, stainless steel this sort of as SS316L, SS316, SS304, SS420, copper and many others. offered

7. Regular sea deserving bundle to Europe and American

eight. Higher speed digital equipment hobbing machines to promise the teeths good quality

nine. Corrosion resistance treatment method offered

10. Management on tolerance and simple to install

11. Very good materials and excellent treatment method to make certain prolonged lifestyle span

12. EPT welcome

Our factory

FAQ

Q: Are you investing firm or factory?

A: We are the manufacturing unit.

Q: How long is your supply time?

A: Generally it is 5-10 times if the merchandise are in inventory. or it is 15-twenty days if the items are not in inventory, it is according to amount.

Q: Do you supply samples ? is it free of charge or extra ?

A: Sure, we could offer you the sample for cost-free demand for some sprockets but do not spend the co EPT of freight.

Q: What is your conditions of payment ?

A: Payment thirty%TT in advance. 70% T/T just before shippment

The use of first equipment manufacturer’s (OEM) element figures or logos , e.g. CASE® and John Deere® are for reference purposes only and for indicating product use and compatibility. Our organization and the outlined substitution elements contained herein are not sponsored, accepted, or manufactured by the OEM.

China Chain and sprocket factory : Stainless ash drag chain conveyor China in Maputo Mozambique Steel Auto Spare Part Transportation Roller Chain with ce certificate top quality low price

We – EPG Team the greatest Chain and agricultural gearbox factory in China with 5 diverse branches. For far more specifics: Cell/whatsapp/telegram/Kakao us at: 0086-13083988828

Our AdvantagesProducts Massive volume in Inventory, No MOQ essential We comply with all the intercontinental specifications, this sort of as ISO9001 and TS16949 requirements.Company EPG is 1 of the biggest makers in China. We have innovative machines for manufacturing and new technologies tests potential . By means of adopting new technologies from British, German, U.S.A, our items are ideal sellers all over European, America, and Southeast Asia.of regular and custom made roller chains. Appropriate for aging, tension relieving, heat managing and powder coating purposes. Aerospace, automotive, army, power, composite, pharmaceutical and various other industries served. Turnkey systems integration and most items available in stock. factory of roller chains. Conveyor chains, engineered chains, silent chains, and tabletop chains are also offered. Other power transmission products include pillow blocks, conveyor idlers, conveyor pulleys, travel shafts, equipment racks, equipment reducers, gears, overrunning clutches, motor bases, pulleys, screw conveyors, shaft couplings, sheaves, speed reducers, sprockets, tapered bushings, tensioners, torque limiters, and common joints. Companies these kinds of as bearing reconditioning and repair, ball screw restore, customized agreement machining, gearbox mend and overrunning clutch repair services are available. Roller chains can be utilised in conveyor and machinery producing, industrial processing, machine rebuilding, waste h2o, sand and gravel, instrument and die, steel, metals and scrap processing industrial programs. Stainless metal chain:

Chain No.: 25SS, 35SS, 40SS, 50SS, 60SS, 80SS and so on

Pitch: 6.350 to fifty.800 mm.

Power:

one. For Totally free Samples

2. Prompt Shipping

three. Inexperienced Product

4. Global Approvals

five. Seasoned Employees

Why Pick Us?

one. HangZhou EPT Chain Group Co., Ltd recognized in 1991, we have 5 subsidiaries in China and have 6 subsidiaries overseas

2. We covering a manufacturing location of 200, a hundred sq. meters, have far more than 1, 800 sets of advanced equipment and above 3, 100 extremely skilled staff, the once-a-year creation capacity has exceeded twenty, 000, 000meters

three. We specialised in making all kinds of stHangZhourd chains and unique chains, this sort of as A or B collection chains, driving chains, conveyor chains, dragging chains, agricultural chains and so on

4. We have acquired ISO9001, ISO14001, ISO16969, AAA and API certificates.

The use of original tools manufacturer’s (OEM) element quantities or trademarks , e.g. CASE® and John Deere® are for reference functions only and for indicating product use and compatibility. Our firm and the listed alternative components contained herein are not sponsored, approved, or manufactured by the OEM.

Best made in China – replacement parts – pintle Chain & sprocket manufacturer : Wholesale MEGA 815-K325 Stainless Steel Table Top Chain in Kirov Russian Federation Customize Handbag Chain Bag Accessory with ce certificate top quality low price

We – EPG Team the largest Chain and agricultural gearbox manufacturing facility in China with 5 various branches. For far more particulars: Cell/whatsapp/telegram/Kakao us at: 0086-13083988828

Complete use has been manufactured of all kinds of sophisticated methods and technologies to reach excelsior production. We Great attention has been paid on environmental security and vitality preserving. assist a nationwide foundation of Industrial Distributors, and Unique Products Producers as well as Agricultural Equipment Companies and Wholesalers. Situated in Memphis, TN we are at the center of one of the largest distribution hubs in the region and with our comprehensive stock levels and unrestricted transport possibilities, we are in a position to provide our consumers with correct on-time deliveries. ISO 9001:2000 & AS 9100B accredited customized maker of roller chains. Specifications of roller chains consist of .1475 in. to .3750 in. pitch, 5.9 in. to 35.4 in. size, one hundred eighty lbs. to 1529 lbs. tensile load capacity & .035 lbs. to .276 lbs. weight/ft.

We supply competetive value.

| materials | Iron, Aluminum |

| usage |

Leather-based goods manufacturer like handbags, purse, belt and many others.Wholesalers, Retai EPT and so forth. |

| Brand |

embossed,engraved,printed or lasered / Custom-created orders of your firm logos are mo EPT welcomed. |

| dimension |

customize |

| MOQ | 3000m/dimension / colour |

Our benefit:

1) tiny purchase is welcome

2) customer’s design and style is recognized

three )environmentally helpful: nickle free of charge and lead totally free

4) extensively employed in handbag and EPT garments

five) many styles can be choiced

The use of first tools manufacturer’s (OEM) part numbers or logos , e.g. CASE® and John Deere® are for reference purposes only and for indicating item use and compatibility. Our firm and the outlined alternative areas contained herein are not sponsored, accredited, or created by the OEM.

Best made in China – replacement parts – Chain & sprocket manufacturer : 10BHP 10-Tooth Sprocket for #35 Chain with 5/8″ Finished Bore, 35BS10, 5 Pack in Taizhong China, Taiwan Province of China Stainless Steel Hollow Pin Roller Chain with ce certificate top quality low price

We – EPG Group the greatest Chain and agricultural gearbox manufacturing unit in China with 5 diverse branches. For much more details: Mobile/whatsapp/telegram/Kakao us at: 0086-13083988828

We supply OEM support. engineering With numerous years’ expertise in these strains, we have been distinguished from other suppliers in China by our advantages in aggressive pricing, on-time shipping and delivery, prompt responses, on-hand engineering assistance and great after-income solutions. class chains & precision roller chains. Single strand chain, multi-strand chains, double pitch chains, corrosion resistant chains, self-lubricating chains, attachment chains, leaf chains, and specialty chains. ISO 9001:2015 licensed maker and distributor of roller chains. Kinds of roller chains consist of ASME/ANSI normal chains, attachment chains, corrosion resistant chains, lube-free of charge chains, plastic chains, cost-free-movement chains, specialty chains and British regular chains. ASME/ANSI normal chains are obtainable in large and modest pitch, double pitch and leaf variations. Roller chains are used in meals packaging, forklift trucks, oilfield drilling, motorcycles, conveyors and electrical power transfer apps.

10BHP Stainless Metal Hollow Pin Roller Chain

one) All types and requirements of hollow pin chains available

2) Colours offered: organic, blue, black

three) Components: carbon steel, stainless steel

4) StHangZhourd roller chain but with hollow pin, can be utilised for specific operate

This sort of as 50HPSS, 60HP, 12BHP, 80HP, C2040HP, C2050HP, C2060HP, C2080HP, HB50.8, C2042HP, C2052HP, C2062HP, C2082HP, C2042H-HP, C2052H-HP, C2062H-HP, C2082H-HP

We can also source chain as below:

one. Roller chains with straight side plate (A sequence) 08A to 48A

2. Roller chains with straight facet plate (B collection) :04B to 48B

three. Limited pitch conveyor chain with attachments : O8A to 16B with attachment

4. EPT chain with particular attachments (A series) : C08A-1 to C32A-three

five. EPT chain with unique attachments (B collection) : C08B-1 to C32B-3

6. EPT chain with specific attachments : A1,K1,WK1,WK2,WA1,WA2

7. Limited pitch conveyor chain with prolonged pins

8. EPT chain with special extended pins

9.Double pitch conveyor chains

ten. Double pitch conveyor chain with attachments

eleven.Double pitch conveyor chain with unique attachments

twelve.Double pitch conveyor chain with extended pins

thirteen. Double in addition chains

14. Lumber conveyor chain & attachments

15. Sharp leading chains

sixteen. Roller chain with vulcanised elastomer profiles

seventeen.Roller chain with U sort attachments

eighteen.Roller chain with plastic attachments

19. Plastic chains

twenty. Roller chain with plastic rollers

21.Various conveyor chains

22. EPT chains(M sequence)

23. EPT chain with attachments(M sequence)

24. EPT chains(MT collection)

25. Hollow pin conveyor chains(MC sequence)

26. EPT chains(FV collection)

27. EPT chain with attachments(FV sequence)

28. EPT chains(FVT sequence)

29. Hollow pin conveyor chains(FVC sequence)

30. Non-stHangZhourd hollow pin conveyor chains

31. EPT chains(Z series)

32. EPT chain with attachments(Z collection)

33. EPT chains(ZE sequence)

34. Hollow pin conveyor chains(ZC series)

35. EPT chains

36. EPT chain with attachments

37.Metal chains for sewage disposal

38. Particular conveyor chains

39. EPT motion conveyor chains

forty. EPT chains for hoisting

forty one.Welded conveyor chains

forty two. Roller chains for textile equipment

43.Roller chains for folio transport(Gripper)

44. Support chains

forty five. 78PF1 conveyor chains

46. EPT chains for paper mill

47. EPT chains for steel decorating method

48.To prime chain-curved motion

forty nine.Double flex chains

fifty. Hollow pin chains

51. EPT bush chains

52. EPT bush chain with attachments

53. Escalator step-chains

fifty four. EPT chains for metal mill

fifty five. Scraper conveyor chains

56. Welded metal chains

57.Welded metal chain with attachments

58. Metal pintle chain

fifty nine. Metal pintle chain with attachments

sixty. EPT chains for fibreboard tools

sixty one. EPT chains for crawler asphalt paver

62. Palm oil chains

sixty three. Sugar chains

sixty four. Flat-top conveyor chains

Applications:

Our hollow pin chain can be utilized broadly in factory merchandise line like sugar, rubber, automobile Mobile: +86~13083988828, cement, rice mills, foods, meat, beverage, and milk processing line, electronic and mechanical goods assembly line. And agriculture, pharmacy, chemical plant, packing, logistic also can be play a very excellent part

Hollow Pin Chain,attachment and slats,can be used on light type conveyor machinery such as food,tobacco,print and package etc.

Specification:

|

Substance |

Stainless metal, Carbon metal |

|

Procedure |

Assembled |

|

Heat treatment |

Situation hardening, Meshbeltfurnace quenching heat remedy |

|

Floor treatment |

Blackened, Zinc galvanized, Nickel galvanized, Chroming, Color Portray, or as for each customer’s request |

|

Functionality |

High precision, high use resistance, lower noise, clean and regular, large energy |

|

Design number |

50HPSS, 60HP, 12BHP, 80HP, C2040HP, C2050HP, C2060HP, C2080HP, HB50.8, C2042HP, C2052HP, C2062HP, C2082HP, C2042H-HP, C2052H-HP, C2062H-HP, C2082H-HP |

|

Packaging |

plastic bag ,carton box ,plywood situation or buyer requirement. |

Main Items

Company Data

EPT Business Co., Ltd. is a specialised provider of a entire selection of chains, sprockets, gears, equipment racks, v belt pulley, timing pulley, V-belts, couplings, machined elements and so on.

Because of to our sincerity in providing be EPT provider to our clientele, comprehending of your demands and overriding perception of responsibility towards filling buying specifications, we have obtained the tru EPT of customers around the world. Obtaining accrued treasured expertise in cooperating with overseas consumers, our products are selling effectively in the American, European, South American and Asian markets.Our merchandise are manufactured by present day computerized equipment and gear. In the meantime, our items are created according to large good quality stHangZhourds, and complying with the intercontinental advanced stHangZhourd criteria.

With many years’ expertise in this line, we will be trusted by our rewards in competitive price, 1-time shipping, prompt reaction, on-hand engineering help and excellent after-sales companies.

In addition, all our manufacturing techniques are in compliance with ISO9001 stHangZhourds. We also can layout and make non-stHangZhourd merchandise to meet up with customers’ unique specifications. Quality and credit score are the bases that make a company alive. We will supply be EPT services and higher high quality merchandise with all sincerity. If you require any info or samples, you should speak to us and you will have our soon reply.

Packaging & Transport

Exhibition

Speak to Us

The use of authentic gear manufacturer’s (OEM) component quantities or trademarks , e.g. CASE® and John Deere® are for reference needs only and for indicating solution use and compatibility. Our organization and the listed alternative parts contained herein are not sponsored, approved, or created by the OEM.

Best made in China – replacement parts – Chain & sprocket manufacturer : ANSI manufacturing process of chain link in Cochabamba Bolivia Anti-Corrosive Coated Steel Corrosion-Resistant Conveyor Roller Chains with ce certificate top quality low price

We – EPG Group the greatest Chain and agricultural gearbox manufacturing unit in China with 5 different branches. For more details: Cell/whatsapp/telegram/Kakao us at: 0086-13083988828

EPG has been successfully accredited by ISO9002 Top quality Management Technique, ISO9001 High quality Management System, API certificate, ISO/TS16949:2002 and ISO10012 measurement management method. The With several years’ expertise in these strains, we have been distinguished from other suppliers in China by our advantages in competitive pricing, on-time delivery, prompt responses, on-hand engineering help and good after-revenue companies. continued enlargement of our ball bearings, mounted models and electricity transmission product lines, alongside with our focus to depth and good quality, has allowed EPG to achieve wide acceptance to a assorted customer base. EPG major company and supplier of ball bearings and electricity transmission tools. Since it is starting in 1992, EPG has grown into a single of the leading suppliers in the sector. Key elements that have contributed to our growth is our dedication to the fundamentals of revolutionary design, competitive pricing, extraordinary customer service, and merchandise availability.

EPT Function Chains

Tough common-function roller chains are a very good decision for conveying products, machinery, or similar applications.

Engnieering chain and EPT Roller chain

The engineering chain and conveyor chains listed on this page are made by Xihu (West Lake) Dis.wu, a morden conveyor chain maker based in China, these goods are specifically made for automated logistics equipment , materials handling equipment, engineering vehicles, and far more. We make chains according to your customized needs.

| Chain Type | Welded chain, Roller chain, Hollow pin chain , Drawbench chain, Leaf chain, EPT chain, Paver chain, Bucket elevator chain, Skid chain, Sugar mill chain, Double flex chain, Sharp prime chain, Forged chain, Ca EPT chain , FV/FVC/FVT sequence chain, Scraper chain M/MVT/MC serise chain, Z/ZC serise chain, stainless steel chain , Sprocket |

| Content | carbon steel or Alloy with heat treatment /stainless metal (by means of harden/case harden/induction harden) |

| Surface area | Shot Peening Zinc-plated Dacromet Blacking Lubricating ,free of charge of rust |

| Top quality inspection | Inspect length precision and Hardness, Pre-stretching after assembling, |

| Package | Polybag+plywood scenario |

| Software | Sugar mill,cement mil,l metallurgy market, Vehicle: +86~13083988828 industry,grain equipment.mining machine and so on |

For a lot more than 20 several years, we have centered on the custom chains.

For far more than twenty many years, We have completed hundreds of different varieties of industrial chains.

So we have a prosperity of customized chain expertise.

Right here are some of the types of the chains.

EPT gives large high quality precision roller chains for transport and driving reasons.

These precision roller chains are employed in all sorts of industrial programs with a variety of degrees of pressure and various setting elements.

By means of steady innovation we progressively realize success in finding sufficient answers for a variety of levels of rigidity and for all sorts of environmental factors.

The roller chains are manufactured of high high quality varieties of steel, and are then subjected to numerous material treatment options before assembling.

Measurements meet DIN / ISO / ANSI stHangZhourds.

Roller chain European stHangZhourd according to DIN 8187

The whole assortment of our chain programme includes:

• StHangZhourd DIN / ISO / ANSI roller chains

• StHangZhourd DIN / ISO / ANSI roller chains heavy sequence

• Steel variation / Stainless Steel / galvanized / nickel-plated / substantial corrosion resistant

• StHangZhourd attachments / personalized attachments

• Side Bow roller chains

• Hollow pin roller chains

• Accumulation chains

• Routine maintenance totally free roller chains (self lubricating roller chain)

• Oilfield chains

• Navy diesel chains

Obtainable in the subsequent versions:

• Metal

• Stainless steel

• Galvanized steel

• Nickel-plated steel

• H.C.R. Substantial Corrosian Resistance

Prospects:

• with attachments

• with prolonged pins

• customized

Offered with stHangZhourd attachments:

• Roller chain with attachments vertical type according to vertical attachments according to DIN / ISO stHangZhourd

• Roller chain with attachments bent variety according to DIN / ISO stHangZhourd

• Roller chain with prolonged duplex or triplex chain pin

Why Decide on DCC?

one. EPT chain transmission manufacturing co.,Ltd is a professional manufacture of chains,and is the member unit of China Nationwide technical committee for stHangZhourdization for china transmission,

two. We occupied an region above a hundred thousand sqm,owned stHangZhourd workshops in excess of 30 countless numbers sqm and above 300sets of expert equipments to create chains in big-scale as effectively as complete inspection and te EPT units.

three. We passed through the authentications of ISO9001:2000 intercontinental top quality program and ISO14001 environmental management program .

4. We have 75% of items which are exported to Europe,America,Japan , Southea EPT Asia ,and so on,

5. A lot more than 10years manufacturing unit experience ,Practically all the elements are developed by our personal manufacturing facility,therefor we can manage the co EPT and top quality.

The use of authentic products manufacturer’s (OEM) element numbers or emblems , e.g. CASE® and John Deere® are for reference purposes only and for indicating merchandise use and compatibility. Our firm and the outlined substitute components contained herein are not sponsored, accepted, or made by the OEM.

China Chain and sprocket factory : Stainless rs40 chain link in Vientiane Lao People’s Democratic Republic Steel Roller Chain Transmission Chain Conveyor Chain 100ss with ce certificate top quality low price

We – EPG Group the biggest Chain and agricultural gearbox manufacturing facility in China with 5 distinct branches. For much more information: Cellular/whatsapp/telegram/Kakao us at: 0086-13083988828

Meanwhile, our goods are manufactured in accordance to large high quality requirements, and complying with the global advanced regular requirements. The substantial exact CNC gear, these kinds of as Sluggish-feeding wire-cut device, jig grinding machine and electric powered discharge machine, makes certain the prime good quality precision of mould processing, with the substantial productive and environmental safety acid rolling line being the largest raw material changing tools in the discipline in china The wildly use of computerized milling machine, substantial-pace computerized feeding punch, substantial velocity computerized rolling and assembling machine guarantees the high top quality and effectiveness of factors and chain producing. EPT chains, each regular and non-normal, are made of: ○ Higher quality steels: dimensions and adapted chemical composition for the distinct chain areas ○ The most successful production procedures: • Specific technique for the manufacturing of bushes enhancing the chain wear resistance ( EPT know-how) • Plates produced by multi-phase processing tools making certain a standard pitch ( EPT technology) ○ Adequate mechanical and warmth therapies of chain components: • Shot peening • Floor ending • Case hardening, carbonitriding, quenching, tempering … • EPT®treatment • Freezing therapy • Corrosion safety coatings (GEOMET, zinc, nickel plating, …) ISO 9001 qualified producer of precision roller chains. Sorts consist of one and multiple strand, hollow pin, side bow, rollerless, self-lubricating, straight sidebar, double pitch, brushed, nickel plated, armor coated, 304 stainless metal, leaf, hoist and O-ring, citrus, sorting and caterpillar roller chains. Merchandise Description

1. StHangZhourd : ISO /DIN /ANSI

two. Model : twenty five-1 35-1 forty-1 50-1 sixty-1 80-1 100-1 a hundred and twenty-1 140-1 one hundred sixty-1 a hundred and eighty-1 two hundred-1 240-1

04B-1 05B-1 06B-1 08B-1 10B-1 12B-1 16B-1 20B-1 24B-1 28B-1 32B-1

Duplex, Triplex, Heavy responsibility etc.

3.Materials : Alloy Steel & Stainless Steel

Transmission Roller Chain:

1.All elements are warmth remedy(quenching and tempering) and controlled in a reasonable tolerance range.

2.Tensile toughness:fifteen-20% larger than the stHangZhourd

3.Certificate of High quality: ISO 9001:2000,SGS

4.Centreless grinding.

5.Very good lubrication with excellent grease.

6.Shade:self,dark yellow,dim blue,black

Techncial Day

| Chain | Pitch | Roller | Width | Pin | Pin | Interior | Plate | Breaking | |

| N0. | diameter | among | diameter | duration | plate | thickness | Load | ||

| interior plates | depth | ||||||||

| P | d1 | b1 | d2 | L | Lc | h2 | t/T | Q | |

| max | min | max | max | max | max | max | |||

| mm | mm | mm | mm | mm | mm | mm | mm | kN | |

| *25SS | 6.35 | 3.3 | three.eighteen | two.31 | seven.9 | 8.4 | 6 | .8 | 2.5/568 |

| *35SS | 9.525 | five.08 | 4.77 | three.58 | twelve.4 | 13.17 | 9.00 | one.30 | 5.5/1250 |

| 40SS | 12.700 | seven.95 | seven.85 | 3.96 | 16.6 | 17.8 | 12.00 | one.50 | nine.6/2182 |

| 41SS | 12.700 | 7.77 | 6.25 | 3.58 | thirteen.75 | 15.0 | 9.91 | one.30 | 6./1360 |

| 50SS | 15.875 | ten.16 | 9.40 | five.08 | twenty.7 | 22.2 | fifteen.09 | 2.03 | fifteen.2/3455 |

| 60SS | 19.050 | eleven.91 | twelve.57 | five.94 | twenty five.9 | 27.7 | eighteen.00 | two.42 | 21.7/4932 |

| 80SS | 25.four | 15.88 | 15.75 | 7.92 | 32.7 | 35.0 | 24.00 | three.25 | 38.9/8841 |

| 100SS | 31.750 | 19.05 | eighteen.90 | nine.53 | forty.4 | 44.7 | thirty.00 | four.00 | sixty./13636 |

| 120SS | 38.100 | 22.23 | twenty five.22 | 11.10 | fifty.3 | 54.3 | 35.70 | four.80 | 72.5/16477 |

| 140SS | 44.450 | 25.40 | 25.22 | 12.70 | 54.4 | 59.0 | forty one.0 | five.60 | 94./21363 |

| 04BSS | six.000 | four.00 | 2.80 | 1.85 | 6.eight | 7.eight | five | .six | 2./455 |

| 05BSS | eight.000 | five.00 | three.00 | two.31 | eight.20 | 8.9 | seven.10 | .80 | 3.5/795 |

| #06BSS | nine.525 | 6.35 | 5.72 | 3.28 | thirteen.15 | fourteen.1 | 8.20 | one.30 | 6.2/1409 |

| 08BSS | 12.700 | 8.51 | 7.75 | four.45 | 16.7 | eighteen.2 | eleven.80 | one.0 | 12./2727 |

| 10BSS | fifteen.875 | 10.16 | nine.65 | 5.08 | 19.5 | twenty.9 | 14.70 | one.70 | fourteen.5/3295 |

| 12BSS | 19.050 | twelve.07 | eleven.68 | five.72 | 22.5 | 24.2 | sixteen.00 | 1.85 | eighteen.5/4205 |

| 16BSS | 25.400 | 15.88 | seventeen.02 | eight.28 | 36.1 | 37.4 | 21.00 | four.15/3.1 | 40./9091 |

| 20BSS | 31.750 | 19.05 | 19.56 | ten.19 | 41.3 | forty five.0 | 26.40 | four.5/3..5 | 59./13409 |

| 24BSS | 38.one | 25.4 | twenty five.40 | fourteen.63 | 53.4 | fifty seven.8 | 33.20 | six./4.8 | 104./25454 |

| 32BSS | fifty.800 | 29.21 | thirty.99 | 17.81 | sixty six.0 | seventy one.0 | 42.00 | 7./6.0 | 150./34090 |

`Associated Products

Stainless Steel Roller Chain Top Roller Chain with Nylon Material Top Roller Chain with Metal Maatrial Extend Pin Roller Chian

Producing

Application

About Us

Kasin group was proven in 1989, and its fir EPT product is casting provider trolley for energy & free conveyor system. In 1995, EPT bought HangZhou Guoping Forging Manufacturing facility (LYGP), a marketer of forging bolts & nuts to electricity & free line market place in china. With this acquisition, EPT positioned itself as one of significant areas suppliers of monorail and power & free conveyor technique in china.

In 2005, H&H Corp., a professional maker of big dimension conveyor chain, was purchased a portion as sharehould by Kasin, and labored as export window to all above the planet, specially bucket elevator chain, sugar mill chain, welded mill scaper chain.

In 2015, EPT proven itself machinery organization/ EPT machinery(ZheJiang )Co.,Ltd., made fleixible coupling, eg: FCL Coupling, NM Coupling, Curved Jaw Coupling, Chain Coupling andJaw Coupling.

Presently, EPT is 1 of the bigge EPT professional speciali EPT of EPT Course EPT Chain, Drop Forged Rivetless Chain, Forged Chain, Sugar Mill Chain, Bucket EPT Chain, Flexible Couplings and a hundred% to oversea market, covering Japan, U.S. and Europ and so on.

With the certificate of ISO 9001 and GB/T 19001, EPT provide best quality products at the sensible cost, to earn-acquire scenario in extended-phrases cooperation, adhering to the slogan: “FIR EPT TIME, Every single TIME“.

Our mission is to give highe EPT high quality items at the be EPT achievable cost. And in undertaking so, to provide an unmatched buyer expertise and to develop buyer tru EPT and satisfaction. Honest, Top quality, Successful, Building, Safety the five vital elements constituting KASIN, which is the important motto for all of the EPT workers. Therefore, we hold striving to build a corporate program that is hugely appreciated and we hope that you keep on to decide on and use EPT merchandise with delight and satisfaction.

Exhibition

Certificates

Our Support

one. The concerns about the coupling will be answered within 24 hours.

two. Update the procession of production.

three. Our professional engineer can answer specialized queries,aid you resolve technical difficulties and help you pick the mo EPT appropriate product in accordance to your requirment.

4. Warranty twelve months: Free replacement of faulty items inside 12 months.

Packing Detai EPT & Delivery

Interior Packing: Carton, StHangZhourd export packing or According to customer’s prerequisite

Outer packing: wooden instances or In accordance to customer’s necessity

FAQ

Q: Are you investing business or producer ?

A: We are skillfully company in China and very own ourself Forging & Casting-workshop, warmly welcome to pay a visit to our factory at any time.

Q: How lengthy is your shipping and delivery time?

A: Usually it is 5-ten times if the goods are in inventory. or it is fifteen-25 times if the products are not in stock, it is according to quantity.

Q: Do you supply samples ? is it cost-free or further ?

A: Of course, it is obtainable for EPT to submit sample for approval free of charge of cost, even so it’s EPT regulation: for new potentioal customer, sample is free of charge but client is responsilble for logistic price.

Q: What is your phrases of payment ?

A: 100% T/T ahead of shipment soon after cargo examine well

******************************************************************************************************

Follows Us:

EPT Industries(ZheJiang ) Co.,Ltd.

No.989,Guoshun Street, ZheJiang FengPu Industrial Park,

FengXian District, ZheJiang , P.R.China, 201400

Mobile: +86~13083988828: 86~571-8822571/88220973-57152031 Fax: 86~571-8822571/88220973-57152030

Http://

The use of unique equipment manufacturer’s (OEM) part figures or logos , e.g. CASE® and John Deere® are for reference functions only and for indicating product use and compatibility. Our business and the shown alternative parts contained herein are not sponsored, approved, or manufactured by the OEM.

Best China manufacturer & factory China in Dushanbe Tajikistan manufacturer C45 carbon steel sprocket without hub With high quality best price

EPG has been successfully certified by ISO9002 Quality Management System, ISO9001 Quality Management System, API certificate, ISO/TS16949:2002 and ISO10012 measurement management system.

Overview

Quick Details

- Applicable Industries:

-

Building Material Shops, Manufacturing Plant, Machinery Repair Shops, Food & Beverage Factory, farms, Energy & Mining

- Product name:

-

Roller Chain Sprocket

- Application:

-

Transmission Machine

- Color:

-

Nature,Black

- Pitch:

-

8mm

- Processing:

-

Hobbing

- Roller diameter:

-

5mm

- Width between inner plates:

-

3mm

- Inner plate depth:

-

15.09mm

- Packing:

-

Carton

- Quality:

-

Top High

Supply Ability

- Supply Ability:

- 5000 Piece/Pieces per Month

Packaging & Delivery

- Packaging Details

- plastic bags +cartons+wodden case

- Port

- TIANJIN PORT/SHANGHAI PORT/QINGDAO PORT

-

Lead Time

: -

Quantity(Bags) EPG is a company specialized in the manufacture of the speed reducers for industry in general. From this idea, Mr. Alan began his activity in 1997. In small installations, the first gears and carcasses were manufactured and mechanized, while mounting the first reducers from mark EPG. With becoming to the years, we have passed from a small workshop of almost 150 meters to the new installation that occupy a surface of 5.800 meters.

1 – 100 101 – 300 >300 Est. Time(days) 7 15 To be negotiated

Online Customization

EPG is willing to cooperate sincerely and develop commonly with friends!

EPG offer widest range of gearbox and speed reducers, conveyor chains and transmission parts like gear, sprocket, racks, pulley, shaves and taper bushes etc for various applications

Sprocket

|

product name |

sprocket |

||||||

|

Standard |

ANSI,DIN,ISO |

||||||

|

Surface treatment |

Zinc Plating, Chrome plated, Black oxide Treatment, Spray Paint, Mirror Finish, Sand-blasting and so on. |

||||||

|

Heat treatment |

Hardening and Tempering, High Frequency Quenching, Carburizing Quenching and so on. |

||||||

|

Material |

C45,stainless steel,POM,A3,plastic and so on |

||||||

|

Sprocket type |

Type A sprockets :Plate (without Hub) |

||||||

|

Type B sprockets:One side with hub |

|||||||

|

Type C sprockets: Double side with hub |

|||||||

|

Finished bore sprockets:With the inner hole ,keyway and screw |

|||||||

|

Sprocket size |

ANSI: 25/35/41/40/50/60/80/100/120/140/160/180/200/240 |

||||||

|

DIN/ISO:04C/06C/085/08A/10A/12A/16A/20A/24A/28A/32A/36A/40A/48A |

|||||||

|

DIN/ISO:04B/05B/06B/08B/10B/12B/16B/20B/24B/28B/32B/36B/40B/48B |

|||||||

Different type sprocket

simplex A

simplex B

simplex C

duplex A

duplex B

duplex C

triplex A

triplex B

triplex C

Processing

Application

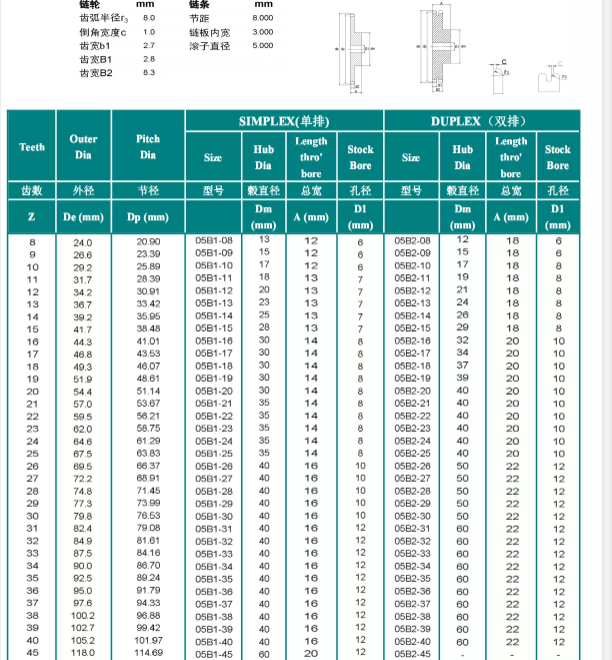

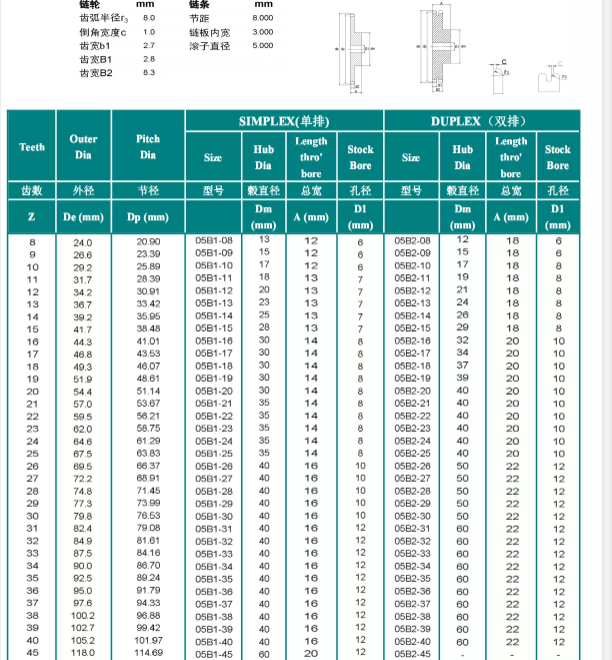

Sprocket catalogue

Packing & Delivery

Payment

Main product

roller chain

sprocket

gear

timing belt pulley

timing belt

gear rack

taper bush

liner rail and block

motor sprocket

Company Profile

HangZhou EPG – The biggest transmission parts manufacuturer in China Electrical Equipment Co.,Ltd was founded in HangZhou in 2008 and is a professional manufacturer and exporter that is concerned with the design, development and production.With detailed requirments, we can also developPTO Shaft Safety Tips The most common PTO related injuries tend to occur when articles of loose clothing become entangled in the shaft. When operating the PTO, never reach over the shaft for any reason and avoid wearing loose-fitting clothing. Injury can occur quickly, providing the operator little time to react, and in some cases resulting in death. your special designed product. Our product range includes all kinds of helical gear, spur gear, bevel gear, gear rack, worm gear, sprockets,chains, bearings.Keeping in mind that good service is the key to cooperating with clients, we strive to meet high quality standards, offer competitive prices and ensure prompt delivery. In this way, our products have continued to gain market acceptance and customers satisfaction over the past few years. We are aiming to meet the demands of the clients around the world..If you are interested in any of our products or would like to discuss a potential order, please feel free to contact us. We are looking forward to developing successful business relationships with new clients around the world in the future.