Product displayProduct Display

- Coupling

- Small flexible coupling

- Pulley

- gear

- rack

- Sprocket

- Spiral bevel gear

- Bevel gear

- Worm Gear

- Expansion coupling sleeve

- Torque limiter

- Timing belt

- Pulley

- Cone sleeve embedded pulley

Email: [email protected]

Coupling

Oldham coupling

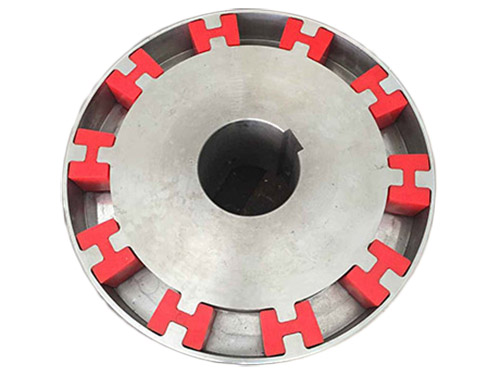

Oldham slider coupling, also called metal slider coupling, may be unfamiliar to the former.In fact, the two mean the same thing.But from the appearance point of view, the cross slider coupling is that the two upper half-turn shafts have grooves on the end faces, and there is an intermediate disc with convex teeth on both end faces.It is generally made of stainless steel or alloy with high wear resistance.So what are the advantages of my Oldham coupling and its working principle?

Advantages of Oldham Coupling

First of all, its appearance is light and easy to install, which saves time for the processing and production of enterprises.Secondly, it is resistant to oil corrosion, and can be electrically insulated. The sliding between the sleeve and the middle piece of different slider elastic bodies can tolerate large radial and angular deviations. The special convex point design in the middle produces a supporting effect, which allows greater tolerance. Angular deviation of, does not produce bending moment, so that the shaft load is reduced to a minimum.

Secondly, the structure is simple, the size range is wide, the moment of inertia is small, the use is convenient, and it is convenient for visual inspection.Super resistance to oil corrosion and electrical insulation, to minimize the shaft load caused by deviation, and the sliding between the shaft sleeve and the middle can allow large radial and angular deviations.

Compared with other couplings, first of all, its appearance looks very light and handy. This kind of thing is the most eye-catching, and the cross slider in the middle has different colors for you to choose from, and it is also not easy to install. It is not troublesome, the biggest thing is that it can be free of maintenance, and it can also be electrically insulated, anti-fouling and anti-corrosion, and its life is relatively long, which is a very economical and suitable coupling. Up.

It is composed of two half couplings with grooves on the end faces and a middle disc with convex teeth on both sides.Because the convex teeth can slide in the groove, the relative displacement between the two shafts during installation and operation can be compensated.The material of the coupling parts can be 45 steel, and the working surface needs to be heat treated to increase its hardness. The flange coupling is a rigid coupling, which uses ordinary flat keys to separate two flanged half couplings. Connect with the two shafts, and then use bolts to connect the two half couplings into one body to transmit movement and torque.

The working principle of the cross slide coupling

Rely on the reamed hole and use the bolt to realize the two-axis centering and rely on the bolt rod to bear the extrusion and shear to transmit the torque; ②The shoulder on one half of the coupling is aligned with the groove on the other half of the coupling Cooperate and center.The bolts connecting the two half couplings can be used with ordinary bolts of grade B, and the torque is transmitted by the frictional moment of the joint surface of the two half couplings.

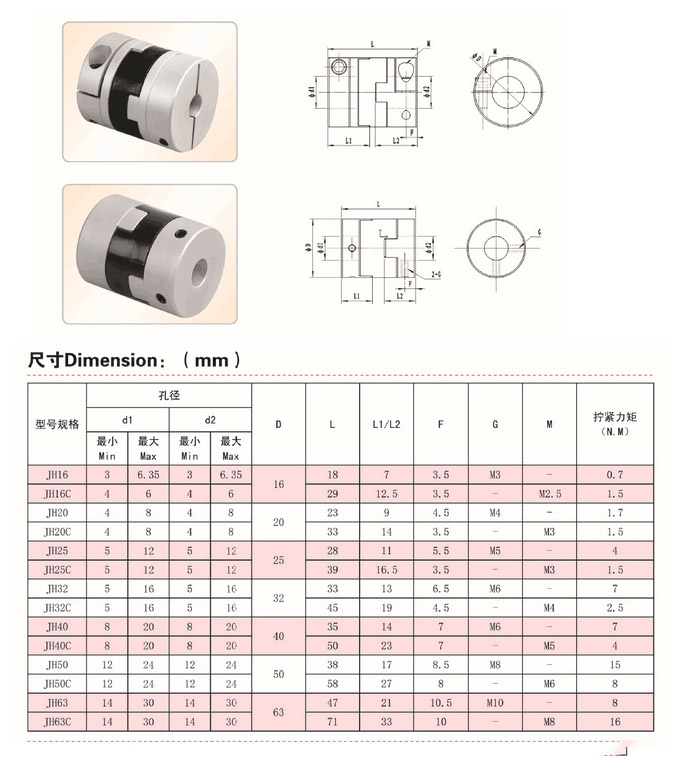

Cross slide coupling size

H type coupling

H type coupling JMI diaphragm coupling

JMI diaphragm coupling GICL drum gear coupling

GICL drum gear coupling