Product displayProduct Display

- Coupling

- Small flexible coupling

- Pulley

- gear

- rack

- Sprocket

- Spiral bevel gear

- Bevel gear

- Worm Gear

- Expansion coupling sleeve

- Torque limiter

- Timing belt

- Pulley

- Cone sleeve embedded pulley

Email: [email protected]

Pulley

H-type synchronous belt wheel

What is H-type synchronous belt wheel:

The H-type synchronous belt wheel is composed of three parts: the rim, the spokes and the hub.When designing the pulley, the structure should be easy to manufacture, with uniform mass distribution, light weight, and avoid excessive internal stress due to casting. Static balance should be performed when V>5m/s, and dynamic balance should be performed when V>25m/s.Timing pulley materials are commonly used gray cast iron, 45# steel, aluminum alloy, copper or engineering plastics.Gray cast iron is the most widely used. When V≤30m/s, HT200 is used. If V≥25~45m/s, it is better to use inoculated cast iron to open cast steel, or use steel plate to stamp a welded pulley.Cast aluminum and plastic can be used for low-power transmission.

Advantages of synchronous belt wheels

1. The transmission of the synchronous pulley is relatively accurate, with a constant transmission ratio when working, and it is not easy to slip.

2. The timing belt wheel has the ability of buffering and damping, so the noise is relatively low when the operation is relatively stable.

3. The synchronous wheel has an excellent efficiency ratio, the maximum can reach 0.98, and the energy saving effect is also very good.

4. The maintenance cost of the synchronous belt is low, it is very convenient to maintain and does not need to use lubricating oil.

5. The timing belt uses green environmental protection materials, so it can work in a harsh environment that does not need to be polluted.

Synchronous wheel structure

1. The main body of the timing pulley and the shaft hole that can be connected to other timing pulleys.

2. The characteristic of the timing pulley is that the middle of the main body will be provided with a trapezoidal cross-section ring groove.

3. On the two end faces of the main body of the timing belt wheel, there will be corresponding annular grooves.

4. The outer ring of the timing belt wheel will be symmetrically designed with multiple arc-shaped or trapezoidal-shaped tooth grooves with equal distances.

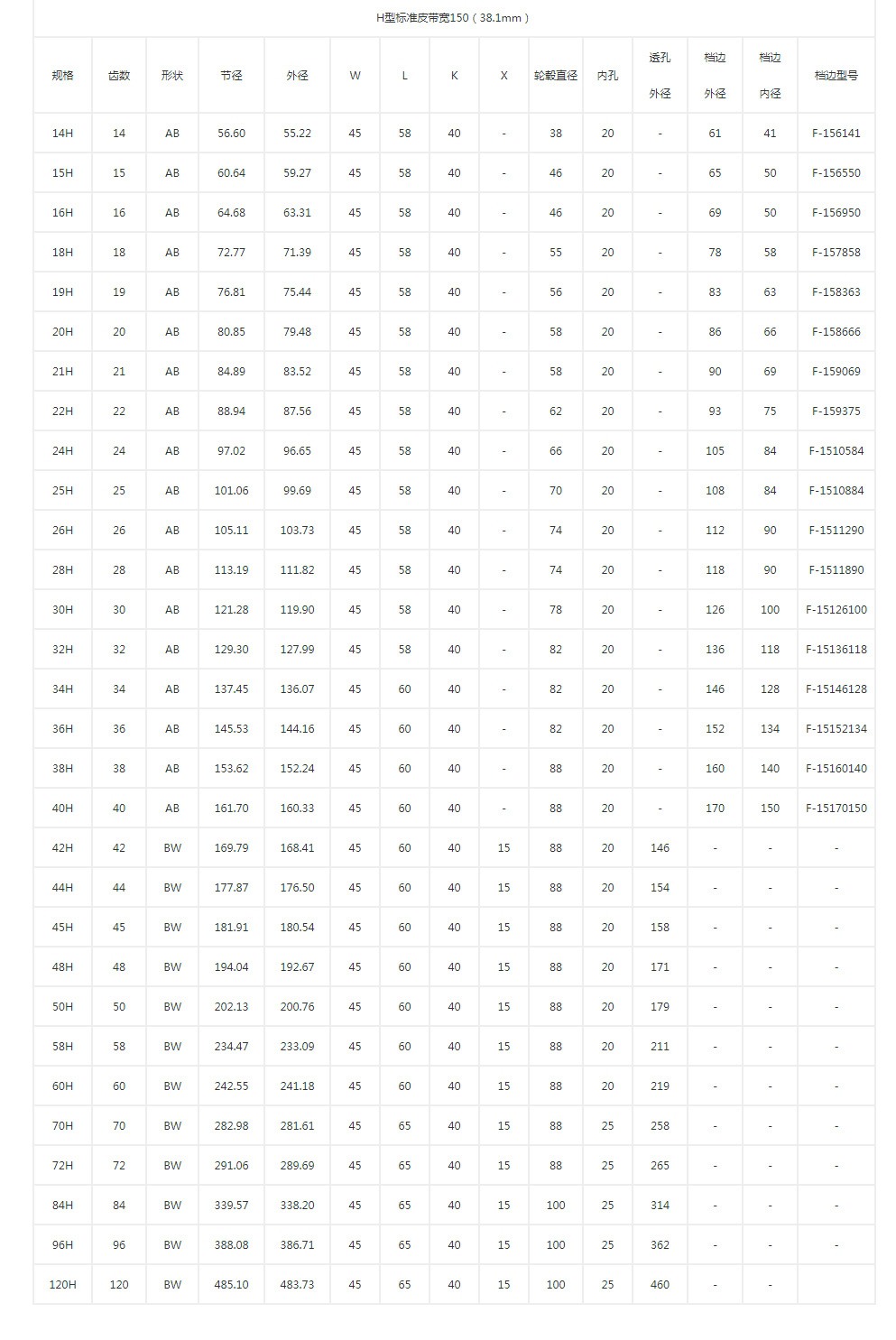

H-type trapezoidal gear synchronous wheel specification size table

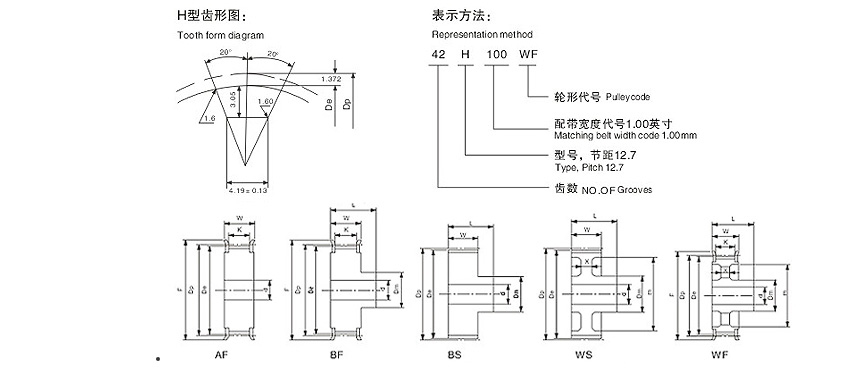

CAD drawing of H type trapezoidal gear synchronous wheel

Synchronous pulley manufacturer sales

Synchronous pulley manufacturer sales Synchronous pulley manufacturers

Synchronous pulley manufacturers Pulley

Pulley