Product displayProduct Display

- Coupling

- Small flexible coupling

- Pulley

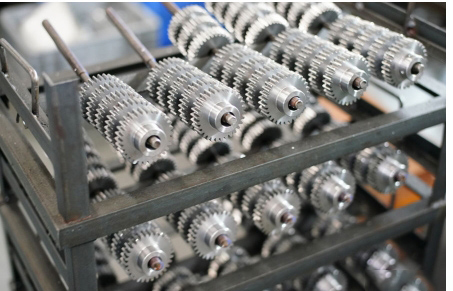

- gear

- rack

- Sprocket

- Spiral bevel gear

- Bevel gear

- Worm Gear

- Expansion coupling sleeve

- Torque limiter

- Timing belt

- Pulley

- Cone sleeve embedded pulley

Email: [email protected]

gear

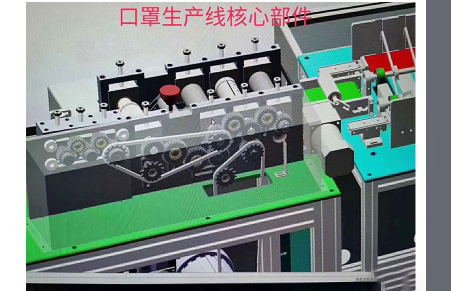

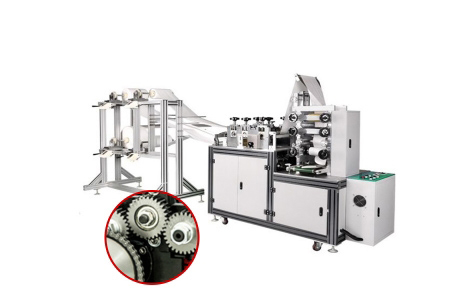

Mask machine gear

The mask machine is mainly composed of electrical system, transmission system, pneumatic system and ultrasonic system.Among them, there are more important parts in the transmission system such as conveyor belts,gear<Motors, reducers, sprockets, chains, etc., adopt precision gears and sprockets for fixed-ratio speed change, which makes the rotation ratio more coordinated and stable.

Mask machine gear-installation:

1. When using a coupling to connect the output shaft, it must be installed and fixed and the two shafts must be parallel. The base must be installed with bolts with a suitable installation hole diameter to ensure that the geared motor is tight and firm.

2. All equipment installed on the output shaft must be lightly installed on the shaft. Do not use hammers or other blunt tools to strike the output shaft to avoid bearing damage caused by over-tightening;

3. Pulleys, iron wheels or gears should be as close as possible to the output bearing to reduce bending stress.Use iron wheels, pulleys, etc., no more than 6 times the diameter of the output shaft to connect with the output shaft.Please use it with H7 tolerance to avoid abnormal noise and shaft surface damage during use;

4. After the installation is completed, you can apply appropriate anti-rust oil or anti-rust paint on the surface of the output shaft to protect the output shaft from rust.

5. According to the power supply voltage, choose a suitable wiring method to connect the wiring in the motor junction box.Wiring errors in the junction box will cause the motor to burn out. According to the rated current on the motor nameplate, it is recommended to select a suitable size cable to power the motor according to the current density of 5A/mm².

6. When using the frequency converter to supply power to the gear reduction motor with brake function, the brake wire (yellow) must be separately provided with AC 220V power supply, and the power supply factory is synchronized with the gear reduction motor power supply;

7. The gear box of the gear reduction motor has been filled with suitable lubricating oil, please do not add lubricating oil before use.After normal use for more than 100000 hours, suitable No. 0 lubricant can be added;