we provide a single-stop remedy for the acquire of mechanical chain,energy transmission areas and pto shaft, agricultural gearboxes products in China.

Overview

Swift Information

- Relevant Industries:

-

Production Plant

- Neighborhood Provider Area:

-

None

- Color:

-

Requires

- Surface treatment:

-

Blacking, Sharpening, Anodization, Chrome Plating, Zinc Plating

- Normal:

-

DIN, ISO/GB, AGMA, JIS,ISO/TS16949:2009

- Tolerance:

-

Outer Diameter Dependent on drawingLength Dimension

- Heat Treatment method:

-

Quenching & Tempering, Carburizing & Quenching

- Product:

-

M1-M8

Supply Capability

- Source Ability:

- 5000 Piece/Parts per Thirty day period

Packaging & Supply

- Packaging Information

- Neutral paper packaging, picket boxes for outer box or according to customer’s demand.

- Port

- Shanghai / Ningbo

-

Guide Time

: -

Our factory has acquired the certification of China’s Farm Equipment Products Good quality Authentication promulgated by the Farm Machinery Products QualiThe shaft floor under the oil seal lip is critical to effective sealing. Any lead remaining from the turning method functions like an oil pump and triggers leaks. Whilst plunge grinding is the most common method for finishing seal journals, the procedure does not ensure satisfactory surfaces.ty Authentication Centre of China.

Quantity(Parts) one – a thousand >1000 Est. Time(times) 15 To be negotiated

Online Customization

We EvIn our company we are informed of the significance of the users’ protection. That is why our PTO’s are created in accordance to authorized rules and European directives and bear the CE signal. A important factor for basic safety assurance is the accession in the products’ development period. By all implies, the users’ information about the correct use of a PTO travel shaft is essential. This indicates, that every single users’ obligation is to read and stick to the basic safety instructions.er-Power Group with 4 branches above 1200 personnel is one of the greatest transmission components and machining products manufacturers in China

Solution Description

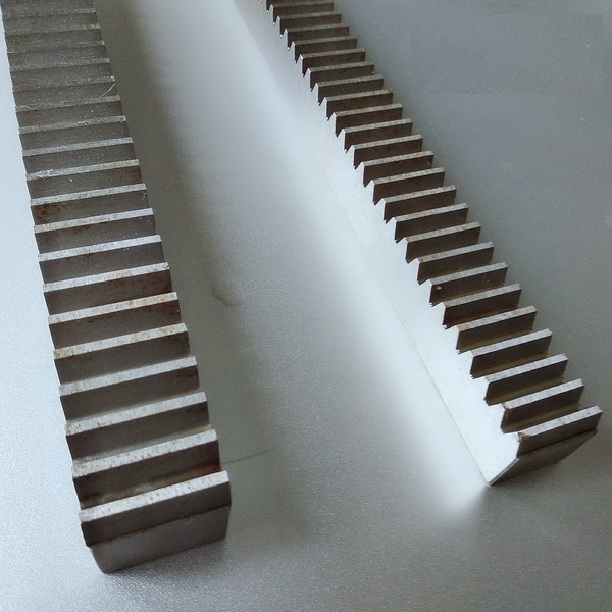

factory producer large precision cnc metal alloy carbon steel inside gear

We specialized in producing vehicle gears , motorbike gears, gearbox, unique vehicle (electricity takeoff, snowmobiles, engineering autos) gears, generator components, stainless metal ice crusher and many others.

|

Materials |

1020,1045,20CrMnTi, etc. |

|

Machining Process |

Gear Hobbing , Gear Shaping, Gear Shaving, Equipment Grinding |

|

Modules |

1., 1.twenty five, 1.5, 1.seventy five, 2., 2.twenty five, 2.5….8. and so forth. |

|

Warmth Remedy |

Carburizing & Quenching, Carbonitriding |

|

Common |

DIN, ISO/GB, AGMA, JIS,ISO/TS16949:2009 |

Packaging & Shipping and delivery