Product Description

Product Description

Coupling Deatails

Name: High precision plum blossom

coupling Model: LM-Material: Aviation Aluminum Alloy

Working temperature: -40 ° C ~ 100 ° C

Support customization: Factory direct sales support customization.

Features:

1.Intermediate Elastomer Connection-Absorbs vibration, compensates for radial, angular, and axial 2.misalignment

3.Oil resistance and electrical insulation

4.Clockwise and counterclockwise rotation characteristics are identical-there are 3 different hardness 5.elastomer

6.Fixation by clamping screw.

|

Model parameter |

ΦD |

L |

LF |

LP |

F |

M |

Tightening screw torque |

|

(N.M) |

|||||||

|

GF-14X22 |

14 |

22 |

14.3 |

6.6 |

3.8 |

M 3 |

0.7 |

|

GF-20X25 |

20 |

25 |

16.7 |

8.6 |

4 |

M 3 |

0.7 |

|

GF-20X30 |

20 |

30 |

19.25 |

8.6 |

5.3 |

M 4 |

1.7 |

|

GF-25X30 |

25 |

30 |

20.82 |

11.6 |

5.6 |

M 4 |

1.7 |

|

GF-25X34 |

25 |

34 |

22.82 |

11.6 |

5.6 |

M 4 |

1.7 |

|

GF-30X35 |

30 |

35 |

23 |

11.5 |

5.75 |

M 4 |

1.7 |

|

GF-30X40 |

30 |

40 |

25.6 |

11.5 |

10 |

M 4 |

1.7 |

|

GF-40X50 |

40 |

50 |

32.1 |

14.5 |

10 |

M 5 |

4 |

|

GF-40X55 |

40 |

55 |

34.5 |

14.5 |

10 |

M 5 |

4 |

|

GF-40X66 |

40 |

66 |

40 |

14.5 |

12.75 |

M 5 |

4 |

|

GF-55X49 |

55 |

49 |

32 |

16.1 |

13.5 |

M 6 |

8.4 |

|

GF-55X78 |

55 |

78 |

46.4 |

16.1 |

15.5 |

M 6 |

8.4 |

|

GF-65X80 |

65 |

80 |

48.5 |

17.3 |

18.1 |

M 8 |

10.5 |

|

GF-65X90 |

65 |

90 |

53.5 |

17.3 |

18.1 |

M 8 |

10.5 |

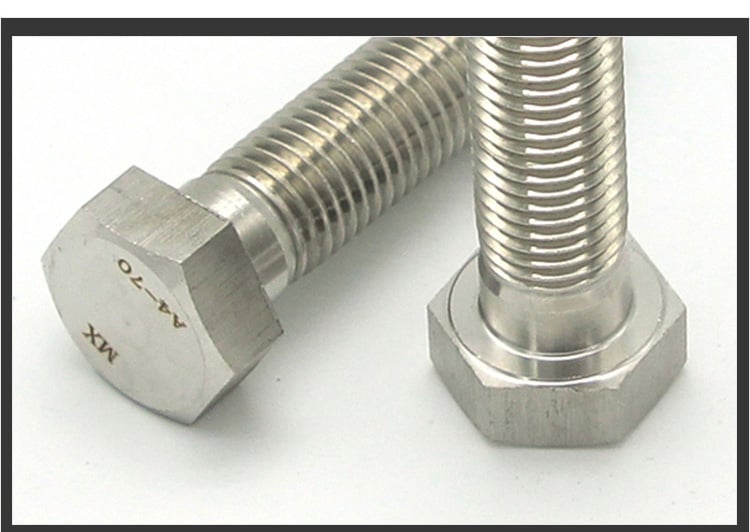

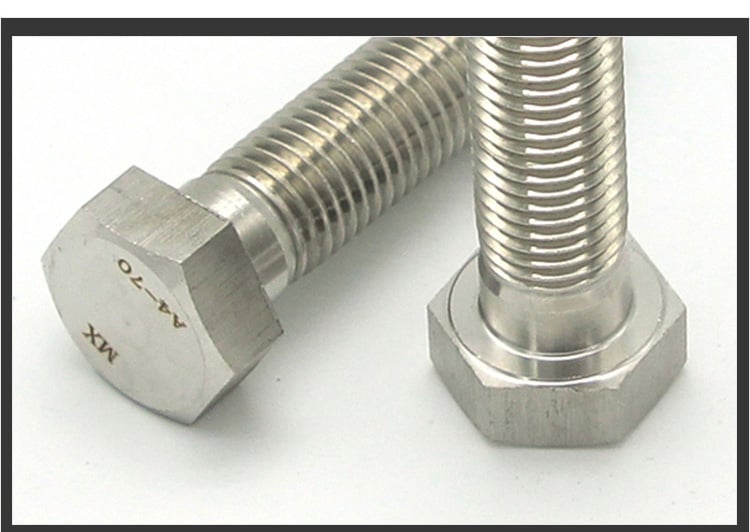

Product Parameters

Detailed Photos

/* January 22, 2571 19:08:37 */!function(){function s(e,r){var a,o={};try{e&&e.split(“,”).forEach(function(e,t){e&&(a=e.match(/(.*?):(.*)$/))&&1

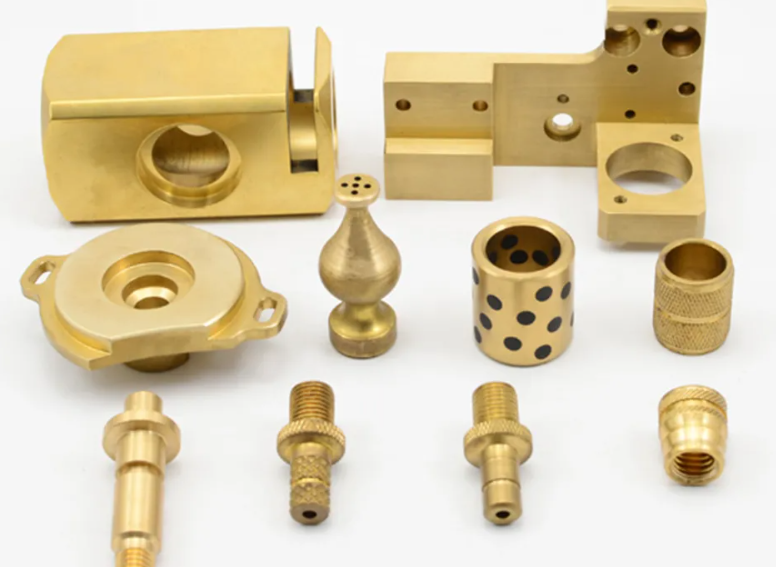

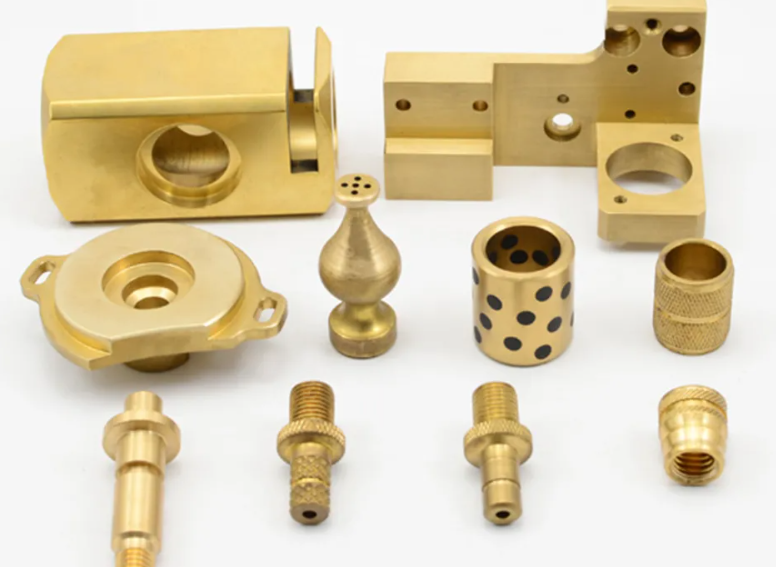

What materials are typically used in manufacturing spider couplings and why?

Spider couplings are constructed using a combination of materials to achieve durability, flexibility, and efficient torque transmission. The choice of materials depends on factors such as application requirements, environmental conditions, and the desired balance between strength and flexibility. Common materials used in manufacturing spider couplings include:

- Aluminum: Aluminum is lightweight and corrosion-resistant, making it suitable for applications where weight reduction is important. It offers good mechanical properties and can be used in various industries.

- Steel: Steel provides excellent strength and durability. It’s often used in heavy-duty applications where high torque transmission is required. Surface treatments can enhance corrosion resistance.

- Stainless Steel: Stainless steel offers corrosion resistance in aggressive environments. It’s commonly used in industries such as food processing, pharmaceuticals, and chemical processing.

- Cast Iron: Cast iron is known for its high compressive strength and wear resistance. It’s suitable for applications requiring robust construction and can handle high torque loads.

- Plastic/Polymer: Certain polymers and plastics, such as polyurethane or nylon, are used for the elastomeric spider element. These materials provide flexibility, vibration dampening, and misalignment compensation.

The choice of materials depends on the specific requirements of the application. For example, aluminum or stainless steel may be chosen for industries requiring corrosion resistance, while steel or cast iron may be selected for heavy-duty applications. The elastomeric spider is typically made from a durable polymer to ensure flexibility and effective torque transmission while accommodating misalignment. Overall, selecting the right materials ensures that spider couplings can withstand the demands of the intended application and provide reliable performance over their lifespan.

What are the symptoms of spider coupling wear or deterioration, and how can they be identified?

Spider couplings, like other mechanical components, can experience wear and deterioration over time due to factors such as torque, misalignment, and environmental conditions. Identifying the symptoms of wear is crucial for maintaining coupling performance and preventing unexpected failures. Here are some common symptoms of spider coupling wear and deterioration:

- Vibration and Noise: Increased vibration or unusual noise during operation can indicate wear in the spider coupling. Excessive wear can lead to reduced dampening of vibrations and increased noise levels.

- Reduced Torque Transmission: If the coupling is no longer transmitting torque efficiently, it may indicate wear or damage to the elastomeric spider. Reduced torque transmission can result in decreased equipment performance.

- Visible Cracks or Tears: Inspect the elastomeric spider for visible cracks, tears, or signs of deformation. These issues can lead to uneven load distribution and compromised coupling function.

- Uneven Shaft Movement: Misalignment caused by wear can lead to uneven movement of connected shafts. This can be observed through irregular motion or wobbling during operation.

- Increased Heat Generation: If the coupling is generating more heat than usual, it may indicate excessive friction due to wear. Overheating can accelerate wear and affect coupling performance.

- Irregular Performance: If machinery or equipment connected by the coupling experiences irregular or unpredictable behavior, it could be a sign of coupling wear affecting torque transmission.

To identify these symptoms, regular visual inspections, vibration analysis, and performance monitoring are recommended. If any of these symptoms are observed, it’s advisable to replace the worn or damaged spider coupling with a new one. Routine maintenance and timely replacement can help ensure the continued reliability and performance of spider couplings in mechanical systems.

What factors should be considered when selecting a spider coupling for a specific application?

Choosing the right spider coupling for a specific application requires careful consideration of various factors to ensure optimal performance and reliability. Here are the key factors to consider:

- Torque Requirements: Determine the torque that the coupling needs to transmit between the shafts. Select a spider coupling that can handle the required torque without exceeding its limitations.

- Misalignment Compensation: Assess the type and degree of misalignment that the coupling needs to accommodate. Different spider coupling designs offer varying levels of misalignment compensation.

- Operating Conditions: Consider the operating environment, including temperature, humidity, and exposure to chemicals or contaminants. Choose a spider coupling with elastomeric material that can withstand these conditions.

- Shaft Diameters: Measure the diameters of the connected shafts. Ensure that the selected spider coupling matches the shaft sizes to achieve a secure and reliable fit.

- Space Limitations: Evaluate the available space for installing the coupling. Choose a compact spider coupling design that fits within the available dimensions.

- Shaft Speed: Determine the rotational speed of the shafts. Ensure that the selected spider coupling can handle the speed range without causing excessive wear or vibrations.

- Vibration Dampening: If vibration reduction is a priority, select a spider coupling with elastomeric material that offers effective vibration dampening properties.

- Electrical Isolation: In applications where electrical isolation is necessary, choose a spider coupling with electrically insulating properties to prevent current transmission between shafts.

- Chemical Compatibility: If the machinery operates with specific chemicals or fluids, ensure that the elastomeric material of the coupling is compatible with these substances.

- Cost Consideration: Evaluate the budget available for the coupling. Consider both the upfront cost and the potential savings from reduced maintenance and downtime.

- Manufacturer Reputation: Choose spider couplings from reputable manufacturers known for producing high-quality and reliable products.

- Application Type: Different industries and applications have unique requirements. Consider the specific demands of the application, such as pumps, compressors, conveyors, etc.

By carefully evaluating these factors, you can select a spider coupling that best matches the requirements of your application, ensuring efficient power transmission, misalignment compensation, and overall system performance.

editor by CX 2024-05-09

China OEM CNC Aluminum Elastic Rubber Spider Jaw Shaft Coupler GF14*22 20*25 25*30 40*50 Shaft Flexible Coupling Ball Screw Plum Coupling

Product Description

Product Description

Coupling Deatails

Name: High precision plum blossom

coupling Model: LM-Material: Aviation Aluminum Alloy

Working temperature: -40 ° C ~ 100 ° C

Support customization: Factory direct sales support customization.

Features:

1.Intermediate Elastomer Connection-Absorbs vibration, compensates for radial, angular, and axial 2.misalignment

3.Oil resistance and electrical insulation

4.Clockwise and counterclockwise rotation characteristics are identical-there are 3 different hardness 5.elastomer

6.Fixation by clamping screw.

|

Model parameter |

ΦD |

L |

LF |

LP |

F |

M |

Tightening screw torque |

|

(N.M) |

|||||||

|

GF-14X22 |

14 |

22 |

14.3 |

6.6 |

3.8 |

M 3 |

0.7 |

|

GF-20X25 |

20 |

25 |

16.7 |

8.6 |

4 |

M 3 |

0.7 |

|

GF-20X30 |

20 |

30 |

19.25 |

8.6 |

5.3 |

M 4 |

1.7 |

|

GF-25X30 |

25 |

30 |

20.82 |

11.6 |

5.6 |

M 4 |

1.7 |

|

GF-25X34 |

25 |

34 |

22.82 |

11.6 |

5.6 |

M 4 |

1.7 |

|

GF-30X35 |

30 |

35 |

23 |

11.5 |

5.75 |

M 4 |

1.7 |

|

GF-30X40 |

30 |

40 |

25.6 |

11.5 |

10 |

M 4 |

1.7 |

|

GF-40X50 |

40 |

50 |

32.1 |

14.5 |

10 |

M 5 |

4 |

|

GF-40X55 |

40 |

55 |

34.5 |

14.5 |

10 |

M 5 |

4 |

|

GF-40X66 |

40 |

66 |

40 |

14.5 |

12.75 |

M 5 |

4 |

|

GF-55X49 |

55 |

49 |

32 |

16.1 |

13.5 |

M 6 |

8.4 |

|

GF-55X78 |

55 |

78 |

46.4 |

16.1 |

15.5 |

M 6 |

8.4 |

|

GF-65X80 |

65 |

80 |

48.5 |

17.3 |

18.1 |

M 8 |

10.5 |

|

GF-65X90 |

65 |

90 |

53.5 |

17.3 |

18.1 |

M 8 |

10.5 |

Product Parameters

Detailed Photos

/* January 22, 2571 19:08:37 */!function(){function s(e,r){var a,o={};try{e&&e.split(“,”).forEach(function(e,t){e&&(a=e.match(/(.*?):(.*)$/))&&1

How does a spider coupling compare to other types of couplings, such as jaw couplings or gear couplings?

Spider couplings, jaw couplings, and gear couplings are all commonly used in mechanical systems for power transmission and misalignment compensation. Each type of coupling has its own unique characteristics and advantages. Here’s a comparison:

- Spider Couplings: Spider couplings, also known as flexible couplings or jaw/spider couplings, use an elastomeric spider to transmit torque and accommodate misalignment. They are known for their flexibility, vibration dampening, and ability to handle angular, radial, and axial misalignment. Spider couplings are suitable for a wide range of applications and are cost-effective solutions for moderate torque requirements and misalignment compensation.

- Jaw Couplings: Jaw couplings consist of two hubs with curved jaws that interlock and transmit torque. They are simple to install and provide a secure connection. However, jaw couplings are less effective in accommodating misalignment compared to spider couplings. They are suitable for applications with minimal misalignment and moderate torque transmission.

- Gear Couplings: Gear couplings use toothed gears to transmit torque between shafts. They are robust and capable of transmitting high torque while accommodating some misalignment. Gear couplings are often used in heavy-duty applications that require precise torque transmission and can tolerate limited misalignment.

When comparing these couplings, spider couplings stand out for their versatility in handling various types of misalignment and providing vibration dampening. Jaw couplings are simpler and suitable for applications with minimal misalignment, while gear couplings excel in heavy-duty applications with high torque requirements. The choice between these couplings depends on the specific requirements of the application, including torque, misalignment compensation, space limitations, and cost considerations.

What are the symptoms of spider coupling wear or deterioration, and how can they be identified?

Spider couplings, like other mechanical components, can experience wear and deterioration over time due to factors such as torque, misalignment, and environmental conditions. Identifying the symptoms of wear is crucial for maintaining coupling performance and preventing unexpected failures. Here are some common symptoms of spider coupling wear and deterioration:

- Vibration and Noise: Increased vibration or unusual noise during operation can indicate wear in the spider coupling. Excessive wear can lead to reduced dampening of vibrations and increased noise levels.

- Reduced Torque Transmission: If the coupling is no longer transmitting torque efficiently, it may indicate wear or damage to the elastomeric spider. Reduced torque transmission can result in decreased equipment performance.

- Visible Cracks or Tears: Inspect the elastomeric spider for visible cracks, tears, or signs of deformation. These issues can lead to uneven load distribution and compromised coupling function.

- Uneven Shaft Movement: Misalignment caused by wear can lead to uneven movement of connected shafts. This can be observed through irregular motion or wobbling during operation.

- Increased Heat Generation: If the coupling is generating more heat than usual, it may indicate excessive friction due to wear. Overheating can accelerate wear and affect coupling performance.

- Irregular Performance: If machinery or equipment connected by the coupling experiences irregular or unpredictable behavior, it could be a sign of coupling wear affecting torque transmission.

To identify these symptoms, regular visual inspections, vibration analysis, and performance monitoring are recommended. If any of these symptoms are observed, it’s advisable to replace the worn or damaged spider coupling with a new one. Routine maintenance and timely replacement can help ensure the continued reliability and performance of spider couplings in mechanical systems.

How do you properly install and maintain a spider coupling in machinery?

Installation:

Proper installation of a spider coupling is essential to ensure its optimal performance and longevity. Here are the steps for installing a spider coupling:

- Ensure Safety: Before starting any installation, make sure the machinery is properly shut down and all energy sources are disconnected.

- Inspect Components: Check the hubs, elastomeric spider, and shafts for any damage or debris. Ensure that the components match the correct specifications.

- Align Shafts: Align the shafts to minimize initial misalignment before inserting the elastomeric spider.

- Insert Spider: Place the elastomeric spider into one of the hubs, ensuring that the lobes or fins are correctly aligned with the grooves in the hub.

- Align Second Hub: Carefully align the second hub with the first one, making sure the spider lobes fit into the grooves of both hubs.

- Press Hubs Together: Gently press the hubs together until they meet. Avoid using excessive force, as this could damage the elastomeric spider.

- Check Alignment: After installation, check the alignment of the shafts and the coupling. Misalignment should not exceed the manufacturer’s recommended limits.

- Tighten Fasteners: Tighten the fasteners on the hubs according to the manufacturer’s torque specifications. Use a torque wrench to ensure proper tightening.

- Verify Clearance: Check for proper clearance between the coupling and surrounding components to prevent interference during operation.

- Run System: Start the machinery and monitor the coupling for any unusual vibrations or noise. Make any necessary adjustments if issues are detected.

Maintenance:

Maintaining a spider coupling is important to ensure its continued performance and prevent premature failure. Here are some maintenance tips:

- Regular Inspection: Periodically inspect the spider coupling for signs of wear, damage, or deterioration. Look for cracks, tears, or other abnormalities in the elastomeric spider.

- Clean Environment: Keep the coupling and surrounding area clean from dirt, debris, and contaminants that could impact its performance.

- Lubrication: Spider couplings are self-lubricating due to the elastomeric material. Avoid using additional lubricants, as they can deteriorate the elastomeric properties.

- Temperature Consideration: Be aware of the temperature range specified by the manufacturer for the elastomeric material. Extreme temperatures can affect the performance and lifespan of the coupling.

- Replace Worn Parts: If the elastomeric spider shows signs of wear, replace it with a new one from the manufacturer. Do not continue using a worn or damaged spider.

- Monitor Vibrations: Regularly monitor the machinery for unusual vibrations or noise, as these can indicate issues with the coupling. Address any problems promptly.

- Follow Manufacturer Guidelines: Adhere to the manufacturer’s recommended maintenance schedule and guidelines for the specific spider coupling model.

Proper installation and regular maintenance contribute to the reliable and efficient operation of a spider coupling in machinery.

editor by CX 2024-05-07

China Best Sales CNC Aluminum Elastic Rubber Spider Jaw Shaft Coupler GF14*22 20*25 25*30 40*50 Shaft Flexible Coupling Ball Screw Plum Coupling

Product Description

Product Description

Coupling Deatails

Name: High precision plum blossom

coupling Model: LM-Material: Aviation Aluminum Alloy

Working temperature: -40 ° C ~ 100 ° C

Support customization: Factory direct sales support customization.

Features:

1.Intermediate Elastomer Connection-Absorbs vibration, compensates for radial, angular, and axial 2.misalignment

3.Oil resistance and electrical insulation

4.Clockwise and counterclockwise rotation characteristics are identical-there are 3 different hardness 5.elastomer

6.Fixation by clamping screw.

|

Model parameter |

ΦD |

L |

LF |

LP |

F |

M |

Tightening screw torque |

|

(N.M) |

|||||||

|

GF-14X22 |

14 |

22 |

14.3 |

6.6 |

3.8 |

M 3 |

0.7 |

|

GF-20X25 |

20 |

25 |

16.7 |

8.6 |

4 |

M 3 |

0.7 |

|

GF-20X30 |

20 |

30 |

19.25 |

8.6 |

5.3 |

M 4 |

1.7 |

|

GF-25X30 |

25 |

30 |

20.82 |

11.6 |

5.6 |

M 4 |

1.7 |

|

GF-25X34 |

25 |

34 |

22.82 |

11.6 |

5.6 |

M 4 |

1.7 |

|

GF-30X35 |

30 |

35 |

23 |

11.5 |

5.75 |

M 4 |

1.7 |

|

GF-30X40 |

30 |

40 |

25.6 |

11.5 |

10 |

M 4 |

1.7 |

|

GF-40X50 |

40 |

50 |

32.1 |

14.5 |

10 |

M 5 |

4 |

|

GF-40X55 |

40 |

55 |

34.5 |

14.5 |

10 |

M 5 |

4 |

|

GF-40X66 |

40 |

66 |

40 |

14.5 |

12.75 |

M 5 |

4 |

|

GF-55X49 |

55 |

49 |

32 |

16.1 |

13.5 |

M 6 |

8.4 |

|

GF-55X78 |

55 |

78 |

46.4 |

16.1 |

15.5 |

M 6 |

8.4 |

|

GF-65X80 |

65 |

80 |

48.5 |

17.3 |

18.1 |

M 8 |

10.5 |

|

GF-65X90 |

65 |

90 |

53.5 |

17.3 |

18.1 |

M 8 |

10.5 |

Product Parameters

Detailed Photos

/* January 22, 2571 19:08:37 */!function(){function s(e,r){var a,o={};try{e&&e.split(“,”).forEach(function(e,t){e&&(a=e.match(/(.*?):(.*)$/))&&1

Are there any industry standards or guidelines for designing and using spider couplings?

Yes, there are industry standards and guidelines that provide recommendations for designing, selecting, and using spider couplings in various mechanical systems. These standards help ensure the safe and reliable operation of spider couplings in industrial applications. Some of the relevant standards include:

- AGMA 9002-B15: This American Gear Manufacturers Association (AGMA) standard provides guidelines for the selection and application of flexible couplings, including spider couplings. It covers topics such as coupling types, misalignment, torque capacity, and lubrication.

- ISO 14691: This International Organization for Standardization (ISO) standard specifies methods for testing the torsional stiffness of flexible couplings, including spider couplings. It outlines procedures for determining the dynamic torsional stiffness and related parameters.

- API 671: This American Petroleum Institute (API) standard provides guidelines for special-purpose couplings used in petroleum, chemical, and gas industry services. It covers design, manufacturing, inspection, and testing requirements for couplings, including those with elastomeric elements.

While these standards offer valuable insights, it’s important to note that specific industry requirements and applications may influence the design and selection of spider couplings. Manufacturers, engineers, and designers should also consider factors such as torque, misalignment compensation, environment, and system dynamics when applying these standards to their designs. Adhering to industry standards ensures that spider couplings are properly designed, installed, and used to meet the intended performance and safety criteria.

Can you explain the concept of torsional stiffness in relation to spider couplings?

Torsional stiffness is a crucial concept in the design and functionality of spider couplings. It refers to the ability of a coupling to resist rotational deformation (twisting) when subjected to a torque load. In other words, torsional stiffness measures how much a coupling can maintain its shape and transmit torque without excessive twisting or deformation.

In the context of spider couplings:

- High Torsional Stiffness: A coupling with high torsional stiffness exhibits minimal angular deflection or twisting when torque is applied. This ensures accurate torque transmission and precise alignment between connected shafts. High torsional stiffness is especially important in applications that require accurate positioning and synchronization.

- Low Torsional Stiffness: A coupling with low torsional stiffness allows for some degree of angular misalignment between shafts and can accommodate slight variations in torque load. This flexibility can be advantageous in applications where misalignment or shock absorption is necessary.

When selecting a spider coupling for a specific application, the torsional stiffness of the coupling needs to be considered based on the requirements of the machinery system. The choice between high and low torsional stiffness depends on factors such as the level of precision needed, the type of load, the degree of misalignment, and the overall performance objectives.

It’s important to note that while torsional stiffness is a key consideration, other factors like the material of the elastomeric spider, size of the coupling, and the type of spider profile also play a role in the coupling’s overall performance and behavior.

What is a spider coupling and how is it used in mechanical systems?

A spider coupling, also known as a jaw coupling or elastomeric coupling, is a type of flexible coupling used to connect two shafts while accommodating misalignment and transmitting torque between them. It consists of three main components: two hubs and an elastomeric spider or insert that fits between them.

The elastomeric spider is typically made of a flexible and durable material, such as rubber or polyurethane, with a series of lobes or fins that fit into matching grooves on the inner surfaces of the hubs. These lobes allow the spider to flex and absorb misalignments between the connected shafts while transmitting torque.

The spider coupling is used in mechanical systems to:

- Transmit Torque: The primary function of a spider coupling is to transmit torque from one shaft to another. As the shafts rotate, the elastomeric spider deforms slightly, allowing the hubs to move relative to each other while maintaining torque transmission.

- Accommodate Misalignment: Spider couplings can accommodate different types of misalignment, including angular, axial, and parallel misalignments, without causing excessive stress on the connected components. This flexibility helps prevent premature wear and failure.

- Dampen Vibrations: The elastomeric material of the spider acts as a shock absorber, dampening vibrations and reducing the transmission of vibrations between the connected shafts. This can improve overall system performance and reduce wear on components.

- Isolate Shock Loads: In applications with sudden changes in torque or shock loads, the spider coupling can absorb and dampen these shocks, protecting the connected components from damage.

- Reduce Maintenance: Spider couplings require minimal maintenance due to their simple design and absence of lubrication points. This can lead to reduced downtime and maintenance costs in industrial machinery.

- Provide Electric Insulation: Spider couplings can provide electrical isolation between the connected shafts, making them suitable for applications where electrical grounding needs to be minimized.

Spider couplings are commonly used in various machinery and equipment, such as pumps, compressors, conveyors, fans, and industrial machinery. They are particularly well-suited for applications that require flexibility, misalignment compensation, vibration reduction, and ease of maintenance.

editor by CX 2024-05-02

China best Gr65 CHINAMFG Coupling Spiders Shaft Connection 134*69*25 Screw Portable Air Compressor Coupling

Product Description

Gr65 CHINAMFG Coupling Spiders Shaft Connection 134*69*25 Screw Portable Air Compressor Coupling

Structure:Jaw / Spider Flexible or Rigid:Flexible

Standard or Nonstandard:Standard Material:PU, or others, PU

Brand Name:Y&F Place of Origin:HangZhou, China (Mainland)

Model Number:Elastic spider Item:spider coupling rubber

Color:Red color Size:GR65

MOQ:1 Pcs, also depend on you needs Specification:134*69*25

Supply Ability

Supply Ability:

3000 Piece/Pieces per Month

Packaging & Delivery

Packaging Details

In standard export packing:suche as carton, plastic bags etc.

HangZhou,China

Lead Time :

In 3-7 days or according to your orders

|

Place of Origin |

HangZhou, China (Mainland) |

|

Brand Name |

YNF/Y&F |

|

Property |

High/low temperature resistance, oil and fuel resistance, weathering resistance, O zone resistance etc. |

|

Shape |

According to your requirement. |

|

Color |

Red color |

|

Material |

Jaw,Spider,Rubber |

|

Delivery |

Within 10 days after payment |

|

Packing |

Plastic bag & carton box or according to your requirements. |

|

Application |

Excavator/Digger |

Why choose us:

Quality Controll

Competitive price

OEM Service

Experience more than 20 years’ experience

Wholesaler We supply a wide range of spare parts for excavators

Main products:

Seal Series:

arm cylinder seal kit, Boom cylinder seal kit, Bucket cylinder seal kit, main pump seal kit, travel motor seal kit,

swing motor seal kit, control valve seal kit, center joint seal kit, track adjust seal kit, bushings,

floating seals, o-ring box, pusher, etc.

Engine parts:

cylinder heads, cylinder blocks, crankshafts, camshafts, connecting rods, water pumps, turbo chargers,

engine assys, fan blades, main bearing and connecting rod bearings, pistons, piston rings, liner kits, etc.

Hydraulic parts:

hydraulic cylinder assembly, gear pump assembly, hydraulic pump assembly, travel motor assembly, final drive assembly, swing motor assembly,

main valve assembly, service valves, gasket kits, etc.

Electric Parts:

solenoid valves, water sensors, pressure sensors, throttle motors, stop solenoid, controllers, monitors, etc.

Other Parts:

seal kits, bushings, floating seals, o-ring box, pushers, couplings, engine cushions, bearings, gears, fuel filter

Product show as below:

|

OD |

ID | H | |

| GR-28 | 65 | 30 | 20 |

| GR-38 | 80 | 38 | 22 |

| GR-42 | 95 | 45 | 20 |

| GR-48 | 105 | 52 | 26 |

| GR-55 | 120 | 60 | 27 |

| GR-65 | 134 | 69 | 25 |

| GR-75 | 160 | 80 | 37 |

| GR-90 | 199 | 100 | 42 |

| GR-100 | 224 | 113 | 38 |

| GR-110 | 225 | 127 | 42.5 |

About us:

Company Information

Yingfeng Construction Machinery Limited established in 1988,having both trading company and owned factory .Office and showroom are located in HangZhou ,Xihu (West Lake) Dis. district. We produce and sell various Excavator Parts,such as coupling,Oil Seal,Hydraulic Parts,Excavator Rubber Parts,Excavator Electric Parts,Excavator wearing Parts,Engine Parts,Excavator Filters,Excavator Gears,Bearings,Excavator A/C Parts,Excavator Undercarriage Parts and Some air compressor couplings.

The parts we supplly can be used

FAQ

/* January 22, 2571 19:08:37 */!function(){function s(e,r){var a,o={};try{e&&e.split(“,”).forEach(function(e,t){e&&(a=e.match(/(.*?):(.*)$/))&&1

Are there any industry standards or guidelines for designing and using spider couplings?

Yes, there are industry standards and guidelines that provide recommendations for designing, selecting, and using spider couplings in various mechanical systems. These standards help ensure the safe and reliable operation of spider couplings in industrial applications. Some of the relevant standards include:

- AGMA 9002-B15: This American Gear Manufacturers Association (AGMA) standard provides guidelines for the selection and application of flexible couplings, including spider couplings. It covers topics such as coupling types, misalignment, torque capacity, and lubrication.

- ISO 14691: This International Organization for Standardization (ISO) standard specifies methods for testing the torsional stiffness of flexible couplings, including spider couplings. It outlines procedures for determining the dynamic torsional stiffness and related parameters.

- API 671: This American Petroleum Institute (API) standard provides guidelines for special-purpose couplings used in petroleum, chemical, and gas industry services. It covers design, manufacturing, inspection, and testing requirements for couplings, including those with elastomeric elements.

While these standards offer valuable insights, it’s important to note that specific industry requirements and applications may influence the design and selection of spider couplings. Manufacturers, engineers, and designers should also consider factors such as torque, misalignment compensation, environment, and system dynamics when applying these standards to their designs. Adhering to industry standards ensures that spider couplings are properly designed, installed, and used to meet the intended performance and safety criteria.

Can you explain the concept of torsional stiffness in relation to spider couplings?

Torsional stiffness is a crucial concept in the design and functionality of spider couplings. It refers to the ability of a coupling to resist rotational deformation (twisting) when subjected to a torque load. In other words, torsional stiffness measures how much a coupling can maintain its shape and transmit torque without excessive twisting or deformation.

In the context of spider couplings:

- High Torsional Stiffness: A coupling with high torsional stiffness exhibits minimal angular deflection or twisting when torque is applied. This ensures accurate torque transmission and precise alignment between connected shafts. High torsional stiffness is especially important in applications that require accurate positioning and synchronization.

- Low Torsional Stiffness: A coupling with low torsional stiffness allows for some degree of angular misalignment between shafts and can accommodate slight variations in torque load. This flexibility can be advantageous in applications where misalignment or shock absorption is necessary.

When selecting a spider coupling for a specific application, the torsional stiffness of the coupling needs to be considered based on the requirements of the machinery system. The choice between high and low torsional stiffness depends on factors such as the level of precision needed, the type of load, the degree of misalignment, and the overall performance objectives.

It’s important to note that while torsional stiffness is a key consideration, other factors like the material of the elastomeric spider, size of the coupling, and the type of spider profile also play a role in the coupling’s overall performance and behavior.

What are the advantages of using a spider coupling in industrial applications?

Spider couplings offer several advantages that make them a popular choice for various industrial applications. Here are the key advantages:

- Misalignment Compensation: Spider couplings can accommodate angular, axial, and parallel misalignments between connected shafts. This ability to compensate for misalignment reduces stress on components and extends equipment lifespan.

- Flexibility: The elastomeric spider provides flexibility that allows for slight movements between the shafts. This flexibility helps prevent excessive wear, reduces vibration transmission, and minimizes the risk of component failure.

- Vibration Dampening: The elastomeric material of the spider acts as a shock absorber, dampening vibrations generated by rotating machinery. This can lead to improved equipment performance, reduced noise, and enhanced operator comfort.

- Easy Installation: Spider couplings have a simple design with minimal components, making them easy to install and replace. Their design eliminates the need for precise alignment during installation, saving time and effort.

- Torque Transmission: Spider couplings efficiently transmit torque from one shaft to another, ensuring that power is effectively transferred between connected components.

- Minimal Maintenance: Spider couplings require minimal maintenance due to their self-lubricating and wear-resistant elastomeric material. This reduces downtime and maintenance costs for industrial machinery.

- Compact Design: Spider couplings have a compact and lightweight design, making them suitable for applications where space is limited. Their small size allows for easy integration into various systems.

- Cost-Effective: Spider couplings are relatively inexpensive compared to other coupling types, making them a cost-effective solution for a wide range of industrial applications.

- Electric Insulation: In applications where electrical isolation is important, spider couplings made from electrically insulating materials can prevent the transmission of electrical currents between shafts.

- Wide Range of Sizes: Spider couplings are available in various sizes and configurations to accommodate different shaft diameters and torque requirements.

Due to these advantages, spider couplings are commonly used in industries such as manufacturing, automation, packaging, material handling, and more, where flexibility, misalignment compensation, and efficient torque transmission are essential for optimal equipment performance.

editor by CX 2024-04-11

China All Size Wholesale Water Well Drilling Pipe Tools Joint API Screw Thread Male Female Adapter Coupling a universal coupling is

Product Description

API drill pipe tool joint adaptor for drilling rod and Hammer

Adapter joint for drill pipe instrument joint coupling for drill pipe connecting

Our income professionals and complex teams recognize specific market regular needs.They can aid you at any time, anywhere! This price tag is a reference price, and the ultimate price tag is subject to the official negotiation consequence of the buyer and the vendor!

Your inquiry will be replied inside of 24hours, wishing to be your lengthy-time period partner. Remember to truly feel cost-free to speak to with me, We will give you the most favorable price tag,we will do our best for you.

Merchandise Description

We also offer other 3″,4″,5″,6″,ten”,twelve” Large Stress DTH Air Drill Hammers and numerous matched drill bits,

Detailed Pictures

Item Parameters

| 60 drill pipe (square buckle) | ||||

| Diameter (mm) | Duration (mm) | Thickness(mm) | Thread kind | Connector duration |

| sixty | one thousand | 6.five | 48*10*2 | 210/one hundred sixty |

| 60 | 1500 | 6.5 | forty eight*10*two | 210/a hundred and sixty |

| sixty | 2000 | six.five | forty eight*ten*2 | 210/one hundred sixty |

| sixty | 3000 | six.five | forty eight*ten*two | 210/one hundred sixty |

| 60 drill pipe (taper buckle) | ||||

| Diameter (mm) | Size (mm) | Thickness(mm) | Thread sort | Connector size |

| sixty | one thousand | 6.five | taper | 210/one hundred sixty |

| 60 | 1500 | 6.5 | taper | 210/one hundred sixty |

| 60 | 2000 | six.5 | taper | 210/one hundred sixty |

| sixty | 3000 | 6.5 | taper | 210/one hundred sixty |

| 76*(seventy three*5.5) drill pipe | ||||

| Diameter (mm) | Duration (mm) | Thickness(mm) | Thread variety | Connector length |

| seventy six | 1000 | 5.5 | API23/8REG | one hundred ninety/180 |

| 76 | 1500 | five.five | API23/8REG | one hundred ninety/a hundred and eighty |

| 76 | 2000 | 5.five | API23/8REG | one hundred ninety/one hundred eighty |

| seventy six | 3000 | five.five | API23/8REG | one hundred ninety/180 |

| 76*4 drill pipe | ||||

| Diameter (mm) | Size (mm) | Thickness(mm) | Thread variety | Connector length |

| 76 | a thousand | 4 | API23/8REG | a hundred ninety/a hundred and eighty |

| 76 | 1500 | four | API23/8REG | a hundred ninety/180 |

| seventy six | 2000 | four | API23/8REG | a hundred ninety/180 |

| seventy six | 3000 | 4 | API23/8REG | 190/180 |

| 89*6.5 one kelly | ||||

| Diameter (mm) | Size (mm) | Thickness(mm) | Thread type | Connector size |

| 89 | one thousand | six.five | NC26 | 200/200 |

| 89 | 1500 | 6.five | NC26 | 200/two hundred |

| 89 | 2000 | six.five | NC26 | 200/two hundred |

| 89 | 3000 | six.5 | NC26 | 200/200 |

| 89*6.5 double aspect drill pipe | ||||

| Diameter (mm) | Duration (mm) | Thickness(mm) | Thread type | Connector length |

| 89 | 1000 | 6.5 | NC26 | three hundred/230 |

| 89 | 1500 | six.5 | NC26 | three hundred/230 |

| 89 | 2000 | 6.5 | NC26 | three hundred/230 |

| 89 | 3000 | six.five | NC26 | three hundred/230 |

| 89 | 6000 | six.five | NC26 | three hundred/230 |

| 102*8.5 single kelly | ||||

| Diameter (mm) | Size (mm) | Thickness(mm) | Thread sort | Connector size |

| 102 | 1000 | 8.5 | NC31 | 220/230 |

| 102 | 1500 | 8.five | NC31 | 220/230 |

| 102 | 2000 | 8.five | NC31 | 220/230 |

| 102 | 3000 | eight.five | NC31 | 220/230 |

| 102*8.5 double facet drill pipe | ||||

| Diameter (mm) | Duration (mm) | Thickness(mm) | Thread kind | Connector size |

| 102 | 1000 | eight.5 | NC31 | 320/205 |

| 102 | 1500 | 8.five | NC31 | 320/205 |

| 102 | 2000 | 8.5 | NC31 | 320/205 |

| 102 | 3000 | 8.five | NC31 | 320/205 |

| 102 | 6000 | 8.five | NC31 | 320/205 |

| 114*8.5 one kelly | ||||

| Diameter (mm) | Size (mm) | Thickness(mm) | Thread kind | Connector duration |

| 114 | 1500 | 8.5 | NC35 | 240/240 |

| 114 | 2000 | eight.five | NC35 | 240/240 |

| 114 | 3000 | 8.5 | NC35 | 240/240 |

| 114*8.5 double side drill pipe | ||||

| Diameter (mm) | Duration (mm) | Thickness(mm) | Thread sort | Connector size |

| 114 | 1500 | eight.five | NC35 | 310/240 |

| 114 | 2000 | eight.five | NC35 | 310/240 |

| 114 | 3000 | eight.five | NC35 | 310/240 |

| 127*8.5 one kelly | ||||

| Diameter (mm) | Duration (mm) | Thickness(mm) | Thread kind | Connector duration |

| 127 | 1500 | 8.5 | NC38 | 230/230 |

| 127 | 2000 | eight.five | NC38 | 230/230 |

| 127 | 3000 | 8.five | NC38 | 230/230 |

| 127 | 4000 | eight.five | NC38 | 230/230 |

| 127 | 5000 | 8.five | NC38 | 230/230 |

| 127*8.5 double side drill pipe | ||||

| Diameter (mm) | Size (mm) | Thickness(mm) | Thread variety | Connector size |

| 127 | 1500 | eight.5 | NC38 | 300/230 |

| 127 | 2000 | 8.5 | NC38 | 300/230 |

| 127 | 3000 | eight.5 | NC38 | 300/230 |

| 127 | 4000 | eight.5 | NC38 | three hundred/230 |

| 127 | 5000 | 8.five | NC38 | three hundred/230 |

Certifications

FAQ

Q: Are you a company or investing company?

A: We are a specialised manufacturer.

Q: What are your primary items, and utilized for?

A: Our products contain main barrel, casing, drill rod, drill rig and other drilling elements.They are used for mineral exploration, geological drilling,

Q: How about the shipping and delivery phrases?

A: 1.Payment: T/T, L/C, Western Union, Paypal, thirty% deposit in advance and relaxation before shipping

two. Min. buy amount: 1 piece.

3. Transportation: By sea, practice.

Q: How about discount?

A: Cost is based on goods and purchase quantity.

Q: Do you take sample order?

A: Indeed certain, remember to get in touch with us for details.

Q: How about your right after-revenue support?

A: As a manufacturer has 20 many years of background we offer you prompt technology assistance for all difficulties and concerns. Besides, we take products return or exchange for quality problem.

Q: In which is your manufacturing facility positioned in?

A: Our manufacturing facility is found in HangZhou town,ZheJiang province, China.

Q: How does your firm control the high quality?

A: High quality very first. In buy to assure large high quality for our merchandise, our always make a serious inspection for all goods and raw components in rigid treatment.

We have attained certification of ISO9001*Yikuang is professional production of drilling equipment, if you want to know more about our goods, make sure you truly feel cost-free to make contact with us.

|

/ Piece | |

50 Pieces (Min. Order) |

###

| Standard: | API |

|---|---|

| Length: | 3m |

| Usage: | Well Drilling, Ore Mining |

| Material: | High Manganese Steel |

| Transport Package: | Iron Frame |

| Specification: | 127mm |

###

| Samples: |

US$ 95/Piece

1 Piece(Min.Order) |

|---|

###

| Customization: |

|---|

###

| 60 drill pipe (square buckle) | ||||

| Diameter (mm) | Length (mm) | Thickness(mm) | Thread type | Connector length |

| 60 | 1000 | 6.5 | 48*10*2 | 210/160 |

| 60 | 1500 | 6.5 | 48*10*2 | 210/160 |

| 60 | 2000 | 6.5 | 48*10*2 | 210/160 |

| 60 | 3000 | 6.5 | 48*10*2 | 210/160 |

| 60 drill pipe (taper buckle) | ||||

| Diameter (mm) | Length (mm) | Thickness(mm) | Thread type | Connector length |

| 60 | 1000 | 6.5 | taper | 210/160 |

| 60 | 1500 | 6.5 | taper | 210/160 |

| 60 | 2000 | 6.5 | taper | 210/160 |

| 60 | 3000 | 6.5 | taper | 210/160 |

| 76*(73*5.5) drill pipe | ||||

| Diameter (mm) | Length (mm) | Thickness(mm) | Thread type | Connector length |

| 76 | 1000 | 5.5 | API23/8REG | 190/180 |

| 76 | 1500 | 5.5 | API23/8REG | 190/180 |

| 76 | 2000 | 5.5 | API23/8REG | 190/180 |

| 76 | 3000 | 5.5 | API23/8REG | 190/180 |

| 76*4 drill pipe | ||||

| Diameter (mm) | Length (mm) | Thickness(mm) | Thread type | Connector length |

| 76 | 1000 | 4 | API23/8REG | 190/180 |

| 76 | 1500 | 4 | API23/8REG | 190/180 |

| 76 | 2000 | 4 | API23/8REG | 190/180 |

| 76 | 3000 | 4 | API23/8REG | 190/180 |

| 89*6.5 single kelly | ||||

| Diameter (mm) | Length (mm) | Thickness(mm) | Thread type | Connector length |

| 89 | 1000 | 6.5 | NC26 | 200/200 |

| 89 | 1500 | 6.5 | NC26 | 200/200 |

| 89 | 2000 | 6.5 | NC26 | 200/200 |

| 89 | 3000 | 6.5 | NC26 | 200/200 |

| 89*6.5 double side drill pipe | ||||

| Diameter (mm) | Length (mm) | Thickness(mm) | Thread type | Connector length |

| 89 | 1000 | 6.5 | NC26 | 300/230 |

| 89 | 1500 | 6.5 | NC26 | 300/230 |

| 89 | 2000 | 6.5 | NC26 | 300/230 |

| 89 | 3000 | 6.5 | NC26 | 300/230 |

| 89 | 6000 | 6.5 | NC26 | 300/230 |

| 102*8.5 single kelly | ||||

| Diameter (mm) | Length (mm) | Thickness(mm) | Thread type | Connector length |

| 102 | 1000 | 8.5 | NC31 | 220/230 |

| 102 | 1500 | 8.5 | NC31 | 220/230 |

| 102 | 2000 | 8.5 | NC31 | 220/230 |

| 102 | 3000 | 8.5 | NC31 | 220/230 |

| 102*8.5 double side drill pipe | ||||

| Diameter (mm) | Length (mm) | Thickness(mm) | Thread type | Connector length |

| 102 | 1000 | 8.5 | NC31 | 320/205 |

| 102 | 1500 | 8.5 | NC31 | 320/205 |

| 102 | 2000 | 8.5 | NC31 | 320/205 |

| 102 | 3000 | 8.5 | NC31 | 320/205 |

| 102 | 6000 | 8.5 | NC31 | 320/205 |

| 114*8.5 single kelly | ||||

| Diameter (mm) | Length (mm) | Thickness(mm) | Thread type | Connector length |

| 114 | 1500 | 8.5 | NC35 | 240/240 |

| 114 | 2000 | 8.5 | NC35 | 240/240 |

| 114 | 3000 | 8.5 | NC35 | 240/240 |

| 114*8.5 double side drill pipe | ||||

| Diameter (mm) | Length (mm) | Thickness(mm) | Thread type | Connector length |

| 114 | 1500 | 8.5 | NC35 | 310/240 |

| 114 | 2000 | 8.5 | NC35 | 310/240 |

| 114 | 3000 | 8.5 | NC35 | 310/240 |

| 127*8.5 single kelly | ||||

| Diameter (mm) | Length (mm) | Thickness(mm) | Thread type | Connector length |

| 127 | 1500 | 8.5 | NC38 | 230/230 |

| 127 | 2000 | 8.5 | NC38 | 230/230 |

| 127 | 3000 | 8.5 | NC38 | 230/230 |

| 127 | 4000 | 8.5 | NC38 | 230/230 |

| 127 | 5000 | 8.5 | NC38 | 230/230 |

| 127*8.5 double side drill pipe | ||||

| Diameter (mm) | Length (mm) | Thickness(mm) | Thread type | Connector length |

| 127 | 1500 | 8.5 | NC38 | 300/230 |

| 127 | 2000 | 8.5 | NC38 | 300/230 |

| 127 | 3000 | 8.5 | NC38 | 300/230 |

| 127 | 4000 | 8.5 | NC38 | 300/230 |

| 127 | 5000 | 8.5 | NC38 | 300/230 |

|

/ Piece | |

50 Pieces (Min. Order) |

###

| Standard: | API |

|---|---|

| Length: | 3m |

| Usage: | Well Drilling, Ore Mining |

| Material: | High Manganese Steel |

| Transport Package: | Iron Frame |

| Specification: | 127mm |

###

| Samples: |

US$ 95/Piece

1 Piece(Min.Order) |

|---|

###

| Customization: |

|---|

###

| 60 drill pipe (square buckle) | ||||

| Diameter (mm) | Length (mm) | Thickness(mm) | Thread type | Connector length |

| 60 | 1000 | 6.5 | 48*10*2 | 210/160 |

| 60 | 1500 | 6.5 | 48*10*2 | 210/160 |

| 60 | 2000 | 6.5 | 48*10*2 | 210/160 |

| 60 | 3000 | 6.5 | 48*10*2 | 210/160 |

| 60 drill pipe (taper buckle) | ||||

| Diameter (mm) | Length (mm) | Thickness(mm) | Thread type | Connector length |

| 60 | 1000 | 6.5 | taper | 210/160 |

| 60 | 1500 | 6.5 | taper | 210/160 |

| 60 | 2000 | 6.5 | taper | 210/160 |

| 60 | 3000 | 6.5 | taper | 210/160 |

| 76*(73*5.5) drill pipe | ||||

| Diameter (mm) | Length (mm) | Thickness(mm) | Thread type | Connector length |

| 76 | 1000 | 5.5 | API23/8REG | 190/180 |

| 76 | 1500 | 5.5 | API23/8REG | 190/180 |

| 76 | 2000 | 5.5 | API23/8REG | 190/180 |

| 76 | 3000 | 5.5 | API23/8REG | 190/180 |

| 76*4 drill pipe | ||||

| Diameter (mm) | Length (mm) | Thickness(mm) | Thread type | Connector length |

| 76 | 1000 | 4 | API23/8REG | 190/180 |

| 76 | 1500 | 4 | API23/8REG | 190/180 |

| 76 | 2000 | 4 | API23/8REG | 190/180 |

| 76 | 3000 | 4 | API23/8REG | 190/180 |

| 89*6.5 single kelly | ||||

| Diameter (mm) | Length (mm) | Thickness(mm) | Thread type | Connector length |

| 89 | 1000 | 6.5 | NC26 | 200/200 |

| 89 | 1500 | 6.5 | NC26 | 200/200 |

| 89 | 2000 | 6.5 | NC26 | 200/200 |

| 89 | 3000 | 6.5 | NC26 | 200/200 |

| 89*6.5 double side drill pipe | ||||

| Diameter (mm) | Length (mm) | Thickness(mm) | Thread type | Connector length |

| 89 | 1000 | 6.5 | NC26 | 300/230 |

| 89 | 1500 | 6.5 | NC26 | 300/230 |

| 89 | 2000 | 6.5 | NC26 | 300/230 |

| 89 | 3000 | 6.5 | NC26 | 300/230 |

| 89 | 6000 | 6.5 | NC26 | 300/230 |

| 102*8.5 single kelly | ||||

| Diameter (mm) | Length (mm) | Thickness(mm) | Thread type | Connector length |

| 102 | 1000 | 8.5 | NC31 | 220/230 |

| 102 | 1500 | 8.5 | NC31 | 220/230 |

| 102 | 2000 | 8.5 | NC31 | 220/230 |

| 102 | 3000 | 8.5 | NC31 | 220/230 |

| 102*8.5 double side drill pipe | ||||

| Diameter (mm) | Length (mm) | Thickness(mm) | Thread type | Connector length |

| 102 | 1000 | 8.5 | NC31 | 320/205 |

| 102 | 1500 | 8.5 | NC31 | 320/205 |

| 102 | 2000 | 8.5 | NC31 | 320/205 |

| 102 | 3000 | 8.5 | NC31 | 320/205 |

| 102 | 6000 | 8.5 | NC31 | 320/205 |

| 114*8.5 single kelly | ||||

| Diameter (mm) | Length (mm) | Thickness(mm) | Thread type | Connector length |

| 114 | 1500 | 8.5 | NC35 | 240/240 |

| 114 | 2000 | 8.5 | NC35 | 240/240 |

| 114 | 3000 | 8.5 | NC35 | 240/240 |

| 114*8.5 double side drill pipe | ||||

| Diameter (mm) | Length (mm) | Thickness(mm) | Thread type | Connector length |

| 114 | 1500 | 8.5 | NC35 | 310/240 |

| 114 | 2000 | 8.5 | NC35 | 310/240 |

| 114 | 3000 | 8.5 | NC35 | 310/240 |

| 127*8.5 single kelly | ||||

| Diameter (mm) | Length (mm) | Thickness(mm) | Thread type | Connector length |

| 127 | 1500 | 8.5 | NC38 | 230/230 |

| 127 | 2000 | 8.5 | NC38 | 230/230 |

| 127 | 3000 | 8.5 | NC38 | 230/230 |

| 127 | 4000 | 8.5 | NC38 | 230/230 |

| 127 | 5000 | 8.5 | NC38 | 230/230 |

| 127*8.5 double side drill pipe | ||||

| Diameter (mm) | Length (mm) | Thickness(mm) | Thread type | Connector length |

| 127 | 1500 | 8.5 | NC38 | 300/230 |

| 127 | 2000 | 8.5 | NC38 | 300/230 |

| 127 | 3000 | 8.5 | NC38 | 300/230 |

| 127 | 4000 | 8.5 | NC38 | 300/230 |

| 127 | 5000 | 8.5 | NC38 | 300/230 |

Types of Coupling

A coupling is a device used to join two shafts together and transmit power. Its primary function is to join rotating equipment and allows for some end movement and misalignment. This article discusses different types of coupling, including Magnetic coupling and Shaft coupling. This article also includes information on Overload safety mechanical coupling.

Flexible beam coupling

Flexible beam couplings are universal joints that can deal with shafts that are offset or at an angle. They consist of a tube with couplings at both ends and a thin, flexible helix in the middle. This makes them suitable for use in a variety of applications, from motion control in robotics to attaching encoders to shafts.

These couplings are made of one-piece materials and are often made of stainless steel or aluminium alloy. However, they can also be made of acetal or titanium. While titanium and acetal are less common materials, they are still suitable for high-torque applications. For more information about beam couplings, contact CZPT Components.

Flexible beam couplings come in a variety of types and sizes. W series couplings are good for general purpose applications and are relatively economical. Stainless steel versions have increased torque capacity and torsional stiffness. Flexible beam couplings made of aluminum are ideal for servo and reverse motion. They are also available with metric dimensions.

Flexible beam couplings are made of aluminum alloy or stainless steel. Their patented slot pattern provides low bearing load and high torsional rigidity. They have a long operational life. They also require zero maintenance and can handle angular offset. Their advantages outweigh the disadvantages of traditional beam couplings.

Magnetic coupling

Magnetic coupling transfers torque from one shaft to another using a magnetic field. These couplings can be used on various types of machinery. These types of transmissions are very useful in many situations, especially when you need to move large amounts of weight. The magnetic field is also very effective at reducing friction between the two shafts, which can be extremely helpful if you’re moving heavy items or machinery.

Different magnetic couplings can transmit forces either linearly or rotated. Different magnetic couplings have different topologies and can be made to transmit force in various geometric configurations. Some of these types of couplings are based on different types of materials. For example, a ceramic magnetic material can be used for applications requiring high temperature resistance.

Hybrid couplings are also available. They have a hybrid design, which allows them to operate in either an asynchronous or synchronous mode. Hysterloy is an alloy that is easily magnetized and is used in synchronous couplings. A synchronous magnetic coupling produces a coupled magnetic circuit.

Magnetic coupling is a key factor in many physical processes. In a crystal, molecules exhibit different magnetic properties, depending on their atomic configuration. Consequently, different configurations produce different amounts of magnetic coupling. The type of magnetic coupling a molecule exhibits depends on the exchange parameter Kij. This exchange parameter is calculated by using quantum chemical methods.

Magnetic couplings are most commonly used in fluid transfer pump applications, where the drive shaft is hermetically separated from the fluid. Magnetic couplings also help prevent the transmission of vibration and axial or radial loads through the drive shaft. Moreover, they don’t require external power sources, since they use permanent magnets.

Shaft coupling

A shaft coupling is a mechanical device that connects two shafts. The coupling is designed to transmit full power from one shaft to the other, while keeping the shafts in perfect alignment. It should also reduce transmission of shock loads. Ideally, the coupling should be easy to connect and maintain alignment. It should also be free of projecting parts.

The shaft couplings that are used in machines are typically made of two types: universal coupling and CZPT coupling. CZPT couplings are designed to correct for lateral misalignment and are composed of two flanges with tongues and slots. They are usually fitted with pins. The T1 tongue is fitted into flange A, while the T2 tongue fits into flange B.

Another type of shaft coupling is known as a “sliced” coupling. This type of coupling compensates for inevitable shaft misalignments and provides high torque. Machined slits in the coupling’s outer shell help it achieve high torsional stiffness and excellent flexibility. The design allows for varying engagement angles, making it ideal for many different applications.

A shaft coupling is an important component of any machine. Proper alignment of the two shafts is vital to avoid machine breakdowns. If the shafts are misaligned, extra force can be placed on other parts of the machine, causing vibration, noise, and damage to the components. A good coupling should be easy to connect and should ensure precise alignment of the shaft. Ideally, it should also have no projecting parts.

Shaft couplings are designed to tolerate a certain amount of backlash, but it must be within a system’s threshold. Any angular movement of the shaft beyond this angle is considered excessive backlash. Excessive backlash results in excessive wear, stress, and breakage, and may also cause inaccurate alignment readings. It is therefore imperative to reduce backlash before the shaft alignment process.

Overload safety mechanical coupling

Overload safety mechanical couplings are devices that automatically disengage when the torque applied to them exceeds a specified limit. They are an efficient way to protect machinery and reduce the downtime associated with repairing damaged machinery. The advantage of overload couplings is their fast reaction time and ease of installation.

Overload safety mechanical couplings can be used in a wide range of applications. Their automatic coupling mechanisms can be used on any face or edge. In addition, they can be genderless, incorporating both male and female coupling features into a single mechanism. This means that they are both safe and gender-neutral.

Overload safety couplings protect rotating power transmission components from overloads. Overload protection devices are installed on electric motors to cut off power if the current exceeds a certain limit. Likewise, fluid couplings in conveyors are equipped with melting plug elements that allow the fluid to escape when the system becomes too hot. Mechanical force transmission devices, such as shear bolts, are designed with overload protection in mind.

A common design of an overload safety mechanical coupling consists of two or more arms and hubs separated by a plastic spider. Each coupling body has a set torque threshold. Exceeding this threshold may damage the spider or damage the jaws. In addition, the spider tends to dampen vibration and absorb axial extension. This coupling style is nearly backlash free, electrically isolating, and can tolerate very little parallel misalignment.

A mechanical coupling may also be a universal joint or jaw-clutch coupling. Its basic function is to connect the driver and driven shafts, and limits torque transfer. These devices are typically used in heavy-duty industries, such as steel plants and rolling mills. They also work well with industrial conveyor systems.

CZPT Pulley

The CZPT Pulley coupling family offers a comprehensive range of couplings for motors of all types. Not only does this range include standard motor couplings, but also servo couplings, which require ultra-precise control. CZPT Pulley couplings are also suitable for engine applications where high shocks and vibrations are encountered.

CZPT Pulley couplings have a “sliced” body structure, which allows for excellent torsional stiffness and strength. They are corrosion-resistant and can withstand high rotational speeds. The couplings’ design also ensures accurate shaft rotation while limiting shaft misalignment.

CZPT Pulley has introduced the CPU Pin Type couplings, which are effective at damping vibration and maintain zero backlash. They are also made from aluminum and are capable of absorbing heat. They come with recessed tightening screws. They can handle speeds up to 4,000 RPM, and are RoHS-compliant.

editor by CX 2023-03-28

China 20050 Red Star-Shaped Coupling for Eco-Pen 450 Screw Valve coefficient of coupling

Item Description

VISEC D45 micro Spare element Stator

This are 3 pcs of a kindo of membrane seals between rotor housing and fluid housing, white color and can be made by PTFE and HDPE.

VISEC D45 micro

On-the-dot dosage with maximum volumetric precision

VISEC D45 micro Range OF Makes use of :

abrasive media

adhesives

silicones

sealing compounds

fat

oils

DESCRIPTION:

The internal geometry of the stator is based mostly on eccentric screw pump techniques.

New producing processes and supplies make it possible to remodel really complicated geometry into this modest design and style. Media in quite small portions can be conveyed entirely volumetrically ahead and backward.

Walle have a lot of a long time production knowledge and business subject application encounter, we aimed at the diverse harsh sealing environments and created a variety of of supplies appropriate for apps. Enhancing all customers earnings and saving all customers value. CZPT computerized manufacturing equipments and superior screening equipments provide a strong promise for the manufacture of higher top quality factors created for Microdispengsing techniques.

If you have any issue for VISEC D45 micro Spare element Stator, make sure you really feel free to make contact with me. We will reply you inside 24 several hours.

|

US $0.1-7.5 / Piece | |

100 Pieces (Min. Order) |

###

| Color: | White and Black |

|---|---|

| Rubber Material: | Elastomer |

| Transport Package: | Box |

| Specification: | Standard Part |

| Trademark: | Walle |

| Origin: | China |

###

| Customization: |

Available

|

|---|

###

|

US $0.1-7.5 / Piece | |

100 Pieces (Min. Order) |

###

| Color: | White and Black |

|---|---|

| Rubber Material: | Elastomer |

| Transport Package: | Box |

| Specification: | Standard Part |

| Trademark: | Walle |

| Origin: | China |

###

| Customization: |

Available

|

|---|

###

Types of Coupling

A coupling is a device used to join two shafts together and transmit power. Its primary function is to join rotating equipment and allows for some end movement and misalignment. This article discusses different types of coupling, including Magnetic coupling and Shaft coupling. This article also includes information on Overload safety mechanical coupling.

Flexible beam coupling

Flexible beam couplings are universal joints that can deal with shafts that are offset or at an angle. They consist of a tube with couplings at both ends and a thin, flexible helix in the middle. This makes them suitable for use in a variety of applications, from motion control in robotics to attaching encoders to shafts.

These couplings are made of one-piece materials and are often made of stainless steel or aluminium alloy. However, they can also be made of acetal or titanium. While titanium and acetal are less common materials, they are still suitable for high-torque applications. For more information about beam couplings, contact CZPT Components.

Flexible beam couplings come in a variety of types and sizes. W series couplings are good for general purpose applications and are relatively economical. Stainless steel versions have increased torque capacity and torsional stiffness. Flexible beam couplings made of aluminum are ideal for servo and reverse motion. They are also available with metric dimensions.

Flexible beam couplings are made of aluminum alloy or stainless steel. Their patented slot pattern provides low bearing load and high torsional rigidity. They have a long operational life. They also require zero maintenance and can handle angular offset. Their advantages outweigh the disadvantages of traditional beam couplings.

Magnetic coupling

Magnetic coupling transfers torque from one shaft to another using a magnetic field. These couplings can be used on various types of machinery. These types of transmissions are very useful in many situations, especially when you need to move large amounts of weight. The magnetic field is also very effective at reducing friction between the two shafts, which can be extremely helpful if you’re moving heavy items or machinery.

Different magnetic couplings can transmit forces either linearly or rotated. Different magnetic couplings have different topologies and can be made to transmit force in various geometric configurations. Some of these types of couplings are based on different types of materials. For example, a ceramic magnetic material can be used for applications requiring high temperature resistance.

Hybrid couplings are also available. They have a hybrid design, which allows them to operate in either an asynchronous or synchronous mode. Hysterloy is an alloy that is easily magnetized and is used in synchronous couplings. A synchronous magnetic coupling produces a coupled magnetic circuit.

Magnetic coupling is a key factor in many physical processes. In a crystal, molecules exhibit different magnetic properties, depending on their atomic configuration. Consequently, different configurations produce different amounts of magnetic coupling. The type of magnetic coupling a molecule exhibits depends on the exchange parameter Kij. This exchange parameter is calculated by using quantum chemical methods.

Magnetic couplings are most commonly used in fluid transfer pump applications, where the drive shaft is hermetically separated from the fluid. Magnetic couplings also help prevent the transmission of vibration and axial or radial loads through the drive shaft. Moreover, they don’t require external power sources, since they use permanent magnets.

Shaft coupling

A shaft coupling is a mechanical device that connects two shafts. The coupling is designed to transmit full power from one shaft to the other, while keeping the shafts in perfect alignment. It should also reduce transmission of shock loads. Ideally, the coupling should be easy to connect and maintain alignment. It should also be free of projecting parts.

The shaft couplings that are used in machines are typically made of two types: universal coupling and CZPT coupling. CZPT couplings are designed to correct for lateral misalignment and are composed of two flanges with tongues and slots. They are usually fitted with pins. The T1 tongue is fitted into flange A, while the T2 tongue fits into flange B.

Another type of shaft coupling is known as a “sliced” coupling. This type of coupling compensates for inevitable shaft misalignments and provides high torque. Machined slits in the coupling’s outer shell help it achieve high torsional stiffness and excellent flexibility. The design allows for varying engagement angles, making it ideal for many different applications.

A shaft coupling is an important component of any machine. Proper alignment of the two shafts is vital to avoid machine breakdowns. If the shafts are misaligned, extra force can be placed on other parts of the machine, causing vibration, noise, and damage to the components. A good coupling should be easy to connect and should ensure precise alignment of the shaft. Ideally, it should also have no projecting parts.

Shaft couplings are designed to tolerate a certain amount of backlash, but it must be within a system’s threshold. Any angular movement of the shaft beyond this angle is considered excessive backlash. Excessive backlash results in excessive wear, stress, and breakage, and may also cause inaccurate alignment readings. It is therefore imperative to reduce backlash before the shaft alignment process.

Overload safety mechanical coupling

Overload safety mechanical couplings are devices that automatically disengage when the torque applied to them exceeds a specified limit. They are an efficient way to protect machinery and reduce the downtime associated with repairing damaged machinery. The advantage of overload couplings is their fast reaction time and ease of installation.

Overload safety mechanical couplings can be used in a wide range of applications. Their automatic coupling mechanisms can be used on any face or edge. In addition, they can be genderless, incorporating both male and female coupling features into a single mechanism. This means that they are both safe and gender-neutral.

Overload safety couplings protect rotating power transmission components from overloads. Overload protection devices are installed on electric motors to cut off power if the current exceeds a certain limit. Likewise, fluid couplings in conveyors are equipped with melting plug elements that allow the fluid to escape when the system becomes too hot. Mechanical force transmission devices, such as shear bolts, are designed with overload protection in mind.

A common design of an overload safety mechanical coupling consists of two or more arms and hubs separated by a plastic spider. Each coupling body has a set torque threshold. Exceeding this threshold may damage the spider or damage the jaws. In addition, the spider tends to dampen vibration and absorb axial extension. This coupling style is nearly backlash free, electrically isolating, and can tolerate very little parallel misalignment.

A mechanical coupling may also be a universal joint or jaw-clutch coupling. Its basic function is to connect the driver and driven shafts, and limits torque transfer. These devices are typically used in heavy-duty industries, such as steel plants and rolling mills. They also work well with industrial conveyor systems.

CZPT Pulley

The CZPT Pulley coupling family offers a comprehensive range of couplings for motors of all types. Not only does this range include standard motor couplings, but also servo couplings, which require ultra-precise control. CZPT Pulley couplings are also suitable for engine applications where high shocks and vibrations are encountered.

CZPT Pulley couplings have a “sliced” body structure, which allows for excellent torsional stiffness and strength. They are corrosion-resistant and can withstand high rotational speeds. The couplings’ design also ensures accurate shaft rotation while limiting shaft misalignment.

CZPT Pulley has introduced the CPU Pin Type couplings, which are effective at damping vibration and maintain zero backlash. They are also made from aluminum and are capable of absorbing heat. They come with recessed tightening screws. They can handle speeds up to 4,000 RPM, and are RoHS-compliant.

editor by czh 2023-01-29

China IEC 61386 20mm 25mm Zinc Die Cast Set Screw EMT Coupling /EMT Pipe Coupling coupling episodes

Item Description

IEC 61386~/8822 0571 mm 25mm zinc die cast Established Screw emt Coupling /EMT Pipe Coupling

Description:

EMT Established Screw Coupling

EMT Coupling – Zinc

EMT zinc Coupling

American Standard

Dimensions: 20MM,25MM,32MM, 40MM, 50MM

Set-screw kind

Material: Zinc Die Forged

TOPELE zinc emt couplings are utilised in dry place to hook up the finishes of 2 unthreaded EMT conduits collectively. CZPT EMT zinc established-screw couplings give concrete restricted connections when taped. In addition, These set-screw couplings eliminate the want to thread bald conduits to match previous threaded couplings. EMT conduit couplings are pure zinc content for superb corrosion protection in damp location.

Specifications:

|

SSCPI-20MM |

20MM |

Set-Screw Variety |

|

SSCPI-25MM |

25MM |

Set-Screw Variety |

|

SSCPI-32MM |

32MM |

Established-Screw Type |

|

SSCPI-40MM |

40MM |

Established-Screw Type |

|

SSCPI-50MM |

50MM |

Set-Screw Type |

Applications:

IEC 61386 ZINC Established SCREW EMT couplings

•Connect & properly CZPT EMT conduit to EMT conduit

•May be utilised indoors and outdoors

•Body made with die-forged zinc alloy

•Set screw made with zinc-plated steel

•Application sort : EMT

•Electrical Product Kind : Common Fitting

•Fitting kind : Coupling

•Paintable/Stainable : No

|

US $0.07-1.02 / Piece | |

1,000 Pieces (Min. Order) |

###

| Color: | Silver |

|---|---|

| IP Rating: | IP68 |

| Surface Treatment: | Galvanised |

| Application: | Electrical Wiring System |

| Material: | Zinc |

| Certification: | IEC61386 |

###

| Samples: |

US$ 0/Piece

1 Piece(Min.Order) |

|---|

###

| Customization: |

Available

|

|---|

###

|

SSCPI-20MM |

20MM |

Set-Screw Type |

|

SSCPI-25MM |

25MM |

Set-Screw Type |

|

SSCPI-32MM |

32MM |

Set-Screw Type |

|

SSCPI-40MM |

40MM |

Set-Screw Type |

|

SSCPI-50MM |

50MM |

Set-Screw Type |

|

US $0.07-1.02 / Piece | |

1,000 Pieces (Min. Order) |

###

| Color: | Silver |

|---|---|

| IP Rating: | IP68 |

| Surface Treatment: | Galvanised |

| Application: | Electrical Wiring System |

| Material: | Zinc |

| Certification: | IEC61386 |

###

| Samples: |

US$ 0/Piece

1 Piece(Min.Order) |

|---|

###

| Customization: |

Available

|

|---|

###

|

SSCPI-20MM |

20MM |

Set-Screw Type |

|

SSCPI-25MM |

25MM |

Set-Screw Type |

|

SSCPI-32MM |

32MM |

Set-Screw Type |

|

SSCPI-40MM |

40MM |

Set-Screw Type |

|

SSCPI-50MM |

50MM |

Set-Screw Type |

What Is a Coupling?

A coupling is a device that connects two shafts together. It transmits power from one to the other and is used to join rotating equipment. It can also allow for some degree of misalignment and end movement. It is used in mechanical engineering and manufacturing. To learn more about couplings, read this article. Mechanical connection between two objectsThe present invention relates to a method and assembly for forming a mechanical connection between two objects. The methods of this invention are suitable for connecting both solid and hollow objects. For example, the method can be used to make mechanical connections between two cylinders. This method is particularly useful for connecting two cylinders that are positioned near each other.

Mechanical connection between two objectsThe present invention relates to a method and assembly for forming a mechanical connection between two objects. The methods of this invention are suitable for connecting both solid and hollow objects. For example, the method can be used to make mechanical connections between two cylinders. This method is particularly useful for connecting two cylinders that are positioned near each other.

Absorbs vibration

A coupling insert is a part of a vehicle’s drivetrain that absorbs vibrations. These inserts are designed to prevent couplings from moving out of phase. However, the coupling inserts themselves can wear out and need to be replaced. Universal joints are an alternative if the coupling is out of phase by more than one degree. In addition, internal bearings in the coupling need to be lubricated and replaced when they begin to show signs of wear.

Another embodiment of the invention includes a flexible coupling 25 that includes rearwardly-extending lugs that extend toward the coupling member 23. These lugs interdigitate with corresponding lugs on the coupling member 23. They are spaced circumferentially. A first elastic member 28 is interposed between lugs 26 and 27, and is adapted to yield in a counterclockwise direction. As a result, it absorbs torsional vibrations.

Blocks heat transfer

Thermal coupling occurs when a solid block is thermally coupled to the air or fluid passing through it. The amount of heat transferred through a solid block depends on the heat transfer coefficients of the materials. This paper presents a numerical model to understand how heat transfers through different block materials. This work also describes the thermal resistance network for a one-dimensional block.

In some cases, thermal coupling increases the heat transfer mechanism. As illustrated in FIG. 1D, a heatpipe coupler 112 couples two heatpipes 110-1 and 110-2. This configuration allows the pipes to be coupled to the heat source and to the condenser. In addition, the heat pipe couplers may have bellows at the ends to help facilitate linear motion.