Product Description

Power Transmission Abrasion-Resistant Elastic Curved Flexible CHINAMFG Star Drive Spider Plum PU Gasket Jaw Rubber Type Coupling

Manufacturer of Couplings, Fluid Coupling, JAW Coupling, can interchange and replacement of lovejoy coupling and so on.

A coupling can interchange and replacement of lovejoy coupling is a device used to connect 2 shafts together at their ends for the purpose of transmitting power. The primary purpose of couplings is to join 2 pieces of rotating equipment while permitting some degree of misalignment or end movement or both. In a more general context, a coupling can also be a mechanical device that serves to connect the ends of adjacent parts or objects. Couplings do not normally allow disconnection of shafts during operation, however there are torque limiting couplings which can slip or disconnect when some torque limit is exceeded. Selection, installation and maintenance of couplings can lead to reduced maintenance time and maintenance cost.

Coupling is a jaw type coupling that works for a variety of light duty to heavy duty motors used in electric power transmission.

This is 1 of our safest types of products. The reason being that these couplings work even when the elastomer fails and there is no metal to metal contact.

They perform in well-standing oil, grease, moisture, sand, and dirt and nearly 850,000 bore combinations that can be customised as per the customer’s needs.

They are used in light-weight, medium, or heavy electrical motors and devices for power transmission through internal combustion.

Features

1. Hubs made of cast iron GG25.

2. Torsionally flexible, maintenance free, vibration-damping.

3. Axial plug-in, fail-safe.

4. Varying elastomer hardness of spiders.

5. Compact design with small flywheel effect.

6 Easy assembly / dis-assembly of the coupling hubs Short mounting length.

Production workshop:

Company information:

/* January 22, 2571 19:08:37 */!function(){function s(e,r){var a,o={};try{e&&e.split(“,”).forEach(function(e,t){e&&(a=e.match(/(.*?):(.*)$/))&&1

Are there any industry standards or guidelines for designing and using spider couplings?

Yes, there are industry standards and guidelines that provide recommendations for designing, selecting, and using spider couplings in various mechanical systems. These standards help ensure the safe and reliable operation of spider couplings in industrial applications. Some of the relevant standards include:

- AGMA 9002-B15: This American Gear Manufacturers Association (AGMA) standard provides guidelines for the selection and application of flexible couplings, including spider couplings. It covers topics such as coupling types, misalignment, torque capacity, and lubrication.

- ISO 14691: This International Organization for Standardization (ISO) standard specifies methods for testing the torsional stiffness of flexible couplings, including spider couplings. It outlines procedures for determining the dynamic torsional stiffness and related parameters.

- API 671: This American Petroleum Institute (API) standard provides guidelines for special-purpose couplings used in petroleum, chemical, and gas industry services. It covers design, manufacturing, inspection, and testing requirements for couplings, including those with elastomeric elements.

While these standards offer valuable insights, it’s important to note that specific industry requirements and applications may influence the design and selection of spider couplings. Manufacturers, engineers, and designers should also consider factors such as torque, misalignment compensation, environment, and system dynamics when applying these standards to their designs. Adhering to industry standards ensures that spider couplings are properly designed, installed, and used to meet the intended performance and safety criteria.

What are the symptoms of spider coupling wear or deterioration, and how can they be identified?

Spider couplings, like other mechanical components, can experience wear and deterioration over time due to factors such as torque, misalignment, and environmental conditions. Identifying the symptoms of wear is crucial for maintaining coupling performance and preventing unexpected failures. Here are some common symptoms of spider coupling wear and deterioration:

- Vibration and Noise: Increased vibration or unusual noise during operation can indicate wear in the spider coupling. Excessive wear can lead to reduced dampening of vibrations and increased noise levels.

- Reduced Torque Transmission: If the coupling is no longer transmitting torque efficiently, it may indicate wear or damage to the elastomeric spider. Reduced torque transmission can result in decreased equipment performance.

- Visible Cracks or Tears: Inspect the elastomeric spider for visible cracks, tears, or signs of deformation. These issues can lead to uneven load distribution and compromised coupling function.

- Uneven Shaft Movement: Misalignment caused by wear can lead to uneven movement of connected shafts. This can be observed through irregular motion or wobbling during operation.

- Increased Heat Generation: If the coupling is generating more heat than usual, it may indicate excessive friction due to wear. Overheating can accelerate wear and affect coupling performance.

- Irregular Performance: If machinery or equipment connected by the coupling experiences irregular or unpredictable behavior, it could be a sign of coupling wear affecting torque transmission.

To identify these symptoms, regular visual inspections, vibration analysis, and performance monitoring are recommended. If any of these symptoms are observed, it’s advisable to replace the worn or damaged spider coupling with a new one. Routine maintenance and timely replacement can help ensure the continued reliability and performance of spider couplings in mechanical systems.

Are there different types of spider couplings available for various uses?

Yes, there are different types of spider couplings available to suit various industrial applications and requirements. These variations in design and material offer flexibility in choosing the right coupling for specific uses. Here are some common types of spider couplings:

- Standard Jaw Couplings: These couplings feature a simple design with two hubs and an elastomeric spider. They are suitable for general-purpose applications that require misalignment compensation and torque transmission.

- Curved Jaw Couplings: These couplings have curved lobes on the elastomeric spider, allowing for increased misalignment compensation and dampening of vibrations. They offer higher torque capacity and are commonly used in pumps, compressors, and conveyors.

- Spider Couplings with Spacer: These couplings include a spacer between the hubs, allowing for greater axial misalignment compensation. They are used in applications with longer distances between shafts.

- Lovejoy Couplings: Lovejoy couplings are a specific brand of spider couplings known for their high torque capacity, durability, and ease of installation. They come in various styles, including standard, curved jaw, and split type.

- Bowex Couplings: Bowex couplings are designed for applications with high torque requirements and aggressive operating conditions. They offer excellent misalignment compensation and are used in heavy-duty machinery.

- Insert Material Variations: Spider couplings come with elastomeric inserts made from various materials such as rubber, polyurethane, and thermoplastic. These materials offer different levels of flexibility, temperature resistance, and chemical resistance.

- Electrically Insulating Spider Couplings: Some spider couplings are designed with electrically insulating materials to prevent electrical current transmission between shafts. These couplings are used in applications where electrical isolation is critical.

The choice of spider coupling type depends on factors such as torque requirements, misalignment compensation needed, operating conditions, and industry-specific requirements. Proper selection ensures optimal performance, extended equipment lifespan, and reduced maintenance needs.

editor by CX 2024-04-09

China manufacturer Power Transmission Abrasion-Resistant Elastic Curved Flexible CHINAMFG Star Drive Spider Plum PU Gasket Jaw Rubber Type Coupling

Product Description

Power Transmission Abrasion-Resistant Elastic Curved Flexible CHINAMFG Star Drive Spider Plum PU Gasket Jaw Rubber Type Coupling

Manufacturer of Couplings, Fluid Coupling, JAW Coupling, can interchange and replacement of lovejoy coupling and so on.

A coupling can interchange and replacement of lovejoy coupling is a device used to connect 2 shafts together at their ends for the purpose of transmitting power. The primary purpose of couplings is to join 2 pieces of rotating equipment while permitting some degree of misalignment or end movement or both. In a more general context, a coupling can also be a mechanical device that serves to connect the ends of adjacent parts or objects. Couplings do not normally allow disconnection of shafts during operation, however there are torque limiting couplings which can slip or disconnect when some torque limit is exceeded. Selection, installation and maintenance of couplings can lead to reduced maintenance time and maintenance cost.

Coupling is a jaw type coupling that works for a variety of light duty to heavy duty motors used in electric power transmission.

This is 1 of our safest types of products. The reason being that these couplings work even when the elastomer fails and there is no metal to metal contact.

They perform in well-standing oil, grease, moisture, sand, and dirt and nearly 850,000 bore combinations that can be customised as per the customer’s needs.

They are used in light-weight, medium, or heavy electrical motors and devices for power transmission through internal combustion.

Features

1. Hubs made of cast iron GG25.

2. Torsionally flexible, maintenance free, vibration-damping.

3. Axial plug-in, fail-safe.

4. Varying elastomer hardness of spiders.

5. Compact design with small flywheel effect.

6 Easy assembly / dis-assembly of the coupling hubs Short mounting length.

Production workshop:

Company information:

/* March 10, 2571 17:59:20 */!function(){function s(e,r){var a,o={};try{e&&e.split(“,”).forEach(function(e,t){e&&(a=e.match(/(.*?):(.*)$/))&&1

What are the common challenges associated with spider coupling misalignment and how can they be addressed?

Misalignment is a common challenge in spider couplings that can lead to reduced efficiency, increased wear, and potential coupling failure. Here are the common challenges associated with misalignment and how they can be addressed:

- Reduced Torque Transmission: Misalignment can decrease the effective torque transmitted between the shafts, leading to inefficiency and potential overload. Regularly check and align the shafts according to the manufacturer’s recommendations to ensure proper torque transmission.

- Vibration and Noise: Misalignment can cause excessive vibrations and noise in the machinery. Implement precision alignment techniques during installation to minimize misalignment-induced vibrations and noise.

- Increased Wear: Misalignment results in uneven loading on the elastomeric spider, causing premature wear and potential failure. Regularly inspect the coupling for signs of wear and replace the elastomeric spider if necessary. Address misalignment promptly to prevent excessive wear.

- Heat Generation: Misalignment can generate heat due to friction between the elastomeric spider and the hubs. This can lead to accelerated wear and reduced coupling lifespan. Proper alignment helps minimize heat generation and associated issues.

- Shaft Fatigue: Severe misalignment can induce shaft fatigue and stress concentrations, leading to shaft failure over time. Avoid excessive misalignment and ensure that the coupling is properly aligned during installation.

- Reduced Service Life: Misalignment puts additional stress on the elastomeric spider, reducing its service life. Proper alignment and maintenance practices can extend the service life of the coupling.

- Performance Variations: Misalignment can lead to variations in performance and inconsistent operation of the machinery. Regularly monitor the coupling’s performance and address any issues promptly to ensure consistent operation.

To address these challenges, it’s crucial to prioritize precision alignment during the installation of the spider coupling. Follow the manufacturer’s guidelines for alignment tolerances and use alignment tools and techniques to achieve accurate alignment. Regular maintenance, including inspections and alignment checks, will help mitigate the negative effects of misalignment and ensure the reliable performance of spider couplings in industrial applications.

Are there any specific maintenance practices for ensuring the longevity of spider couplings?

Yes, implementing proper maintenance practices is crucial for ensuring the longevity and optimal performance of spider couplings. Here are some specific maintenance practices to consider:

- Regular Inspections: Conduct routine visual inspections of the coupling to identify any signs of wear, damage, or misalignment. Regular inspections allow you to detect issues early and address them before they escalate.

- Lubrication: Follow the manufacturer’s recommendations for lubrication intervals and use the appropriate lubricant. Proper lubrication reduces friction, prevents excessive wear, and maintains coupling efficiency.

- Alignment Checks: Ensure that the shafts connected by the coupling are properly aligned. Misalignment can accelerate wear and compromise coupling performance. Regular alignment checks are essential, especially after maintenance or changes in operating conditions.

- Torque Checks: Periodically check the torque values of fasteners such as bolts, nuts, and screws that secure the coupling components. Proper torque ensures the coupling remains securely fastened.

- Temperature Monitoring: Monitor the operating temperature of the coupling during normal operation. Abnormally high temperatures can indicate excessive friction and potential issues with the coupling.

- Environmental Considerations: If the machinery is operating in harsh or corrosive environments, take appropriate measures to protect the coupling from contaminants, chemicals, and moisture.

- Replacement of Elastomeric Spider: The elastomeric spider is a critical component of the coupling. Replace it if you notice signs of wear, cracks, tears, or deformation. Follow the manufacturer’s recommended replacement intervals.

- Documentation: Maintain records of maintenance activities, inspections, and any repairs performed on the coupling. This documentation helps track the history of the coupling and informs future maintenance decisions.

- Training and Education: Ensure that maintenance personnel are trained in proper coupling maintenance practices. This includes handling, installation, and lubrication procedures.

By adhering to these maintenance practices, you can extend the lifespan of spider couplings, reduce the likelihood of unexpected failures, and ensure the continued reliability of machinery systems.

How do you properly install and maintain a spider coupling in machinery?

Installation:

Proper installation of a spider coupling is essential to ensure its optimal performance and longevity. Here are the steps for installing a spider coupling:

- Ensure Safety: Before starting any installation, make sure the machinery is properly shut down and all energy sources are disconnected.

- Inspect Components: Check the hubs, elastomeric spider, and shafts for any damage or debris. Ensure that the components match the correct specifications.

- Align Shafts: Align the shafts to minimize initial misalignment before inserting the elastomeric spider.

- Insert Spider: Place the elastomeric spider into one of the hubs, ensuring that the lobes or fins are correctly aligned with the grooves in the hub.

- Align Second Hub: Carefully align the second hub with the first one, making sure the spider lobes fit into the grooves of both hubs.

- Press Hubs Together: Gently press the hubs together until they meet. Avoid using excessive force, as this could damage the elastomeric spider.

- Check Alignment: After installation, check the alignment of the shafts and the coupling. Misalignment should not exceed the manufacturer’s recommended limits.

- Tighten Fasteners: Tighten the fasteners on the hubs according to the manufacturer’s torque specifications. Use a torque wrench to ensure proper tightening.

- Verify Clearance: Check for proper clearance between the coupling and surrounding components to prevent interference during operation.

- Run System: Start the machinery and monitor the coupling for any unusual vibrations or noise. Make any necessary adjustments if issues are detected.

Maintenance:

Maintaining a spider coupling is important to ensure its continued performance and prevent premature failure. Here are some maintenance tips:

- Regular Inspection: Periodically inspect the spider coupling for signs of wear, damage, or deterioration. Look for cracks, tears, or other abnormalities in the elastomeric spider.

- Clean Environment: Keep the coupling and surrounding area clean from dirt, debris, and contaminants that could impact its performance.

- Lubrication: Spider couplings are self-lubricating due to the elastomeric material. Avoid using additional lubricants, as they can deteriorate the elastomeric properties.

- Temperature Consideration: Be aware of the temperature range specified by the manufacturer for the elastomeric material. Extreme temperatures can affect the performance and lifespan of the coupling.

- Replace Worn Parts: If the elastomeric spider shows signs of wear, replace it with a new one from the manufacturer. Do not continue using a worn or damaged spider.

- Monitor Vibrations: Regularly monitor the machinery for unusual vibrations or noise, as these can indicate issues with the coupling. Address any problems promptly.

- Follow Manufacturer Guidelines: Adhere to the manufacturer’s recommended maintenance schedule and guidelines for the specific spider coupling model.

Proper installation and regular maintenance contribute to the reliable and efficient operation of a spider coupling in machinery.

editor by CX 2024-02-13

China manufacturer & factory supplier for S in Warsaw Poland series solid shaft helical worm 90 degree drive gearbox power transmission gearbox for conveyor speed reducer 1 30 With high quality best price & service

No other variety of chains can beat EPG for range. Aside from traditional roller chains of all kinds and dimensions, roller chains with attachments and double pitch roller chains, we also supply unique chains such as grip chains, accumulation chains, elastomeric profile chains, leaf chains, bushed conveyor chains, hollow pin chains and several other designs. Routine maintenance-free of charge or corrosion-evidence chains are offered for specific applications. Our pin oven chains and tube conveyor chains allow a vast range of options for the effective production and the best possible conveying of cans and tubes. Discover out far more about our productIn 2000, EPG took the lead in gaining ISO14001 environment administration certification and thereafter handed the inspection of thoroughly clean manufacturing and recycling economic system, successful the title of “Zhejiang Environmentally friendly Company”.

Overview

Quick Particulars

- Applicable Industries:

-

Manufacturing Plant, Equipment Restore Retailers, Foodstuff & Beverage Manufacturing unit, Farms

- Location of Origin:Zhejiang, China

- Brand Title:

-

OEM

- Gearing Arrangement:

-

Worm

-

Output Torque:

In our revenue program we offer you regular and broad-angle PTO push shafts. Regarding the customers’ requirements there are distinct measurements, lengths and protection aspects (clutches) accessible. -

one hundred~62800N.m

- Input Pace:

-

1450/960rpm

- Output Velocity:

-

fourteen-280rpm

- Ratio:

-

seven.5~one hundred

- Certification:

-

ISO9001-2008

- Mount Situation:

-

Foot Mounted

- Bearing:

-

C&U,LYC,ZWZ

Offer Potential

- Provide Ability:

- 3000 Device/Units per Thirty day period

Packaging & Delivery

-

EPG Equipment is situated in XiHu Area HangZhou Zhejiang ,China. It is 30km from our manufacturing unit to HangZhou global airport.

- Packaging Information

- Wooden packing containers , Cantons packed in 1 pallet

- Port

- Ningbo Port, Shanghai Port

Online Customization

Worm gears are generally manufactured by hobbing with a hob or cutting resource very equivalent to the worm that the equipment mates with. The worm might be turned, hobbed, milled, or floor.

S collection sound shaft helical worm ninety degree push gearbox is one variety of Helical worm gearbox ,designed as Modularization and substantial-stainless solid iron situation . It is combination of helical equipment and worm gear ,which with greater performance and toughness than easy aluminum worm gearbox . Owing to their exceptional performance, these drives can be utilised in every industrial sector and tailored to individual torque and velocity requirements. The gear ratios afforded by the helical-worm gear stage and the minimal sounds levels for the duration of operation make these gearmotors best minimal-cost remedies for straightforward programs

1) Output speed: .6~1,028r/min

two) Output torque: up to 4530N.m

3) Motor electricity: .12~22kW

4) Mounted sort: foot-mounted and flange-mounted mounting

Gear Materials | 20CrMnTi |

Case Materials | HT250 |

Shaft Material | 20CrMnTi |

Equipment Processing | Grinding complete by HOFLER Grinding Devices |

Color | Custom-made |

Sound Examination | Bellow 65dB |

Machining precision of gears | accurate grinding, 6 Grade |

Heat remedy | tempering, cementiting, quenching,and many others. |

Brand of bearings | C&U ,HRB,LYC,ZWZ.SKF,NSK |

Model of oil seal | NAK or other model |

Noise (MAX) | sixty five~70dB |

Temp. increase (MAX) | 40 C |

Temp. increase (Oil)(MAX) | 50 C |

Packing Specifics : Standard carton/Pallet/Normal wooden scenario

Shipping and delivery Particulars : 15-30 doing work times upon payment

| Precision Planetary gearbox | Robot RV gearbox pace reducer |

| Custom made made Non-standard Gearbox | UDL Sequence Variator |

| PYZ Collection Helical Tooth Shaft Mounted Reducer | 8000 Sequence Cycloidal Reducer |

| SLT Series Spiral Bevel Gearbox | SLSWL Sequence Worm Screw Jack |

| SLP Sequence Planetary Reducer | SLH/SLB Sequence Large Power Reducer |

| NMRV Collection Worm Reducer | BKM Collection Helical-hypoid Reducer |

| SLRC Sequence Helical Reducer | SLSMR Sequence Shaft Mounted Reducer |

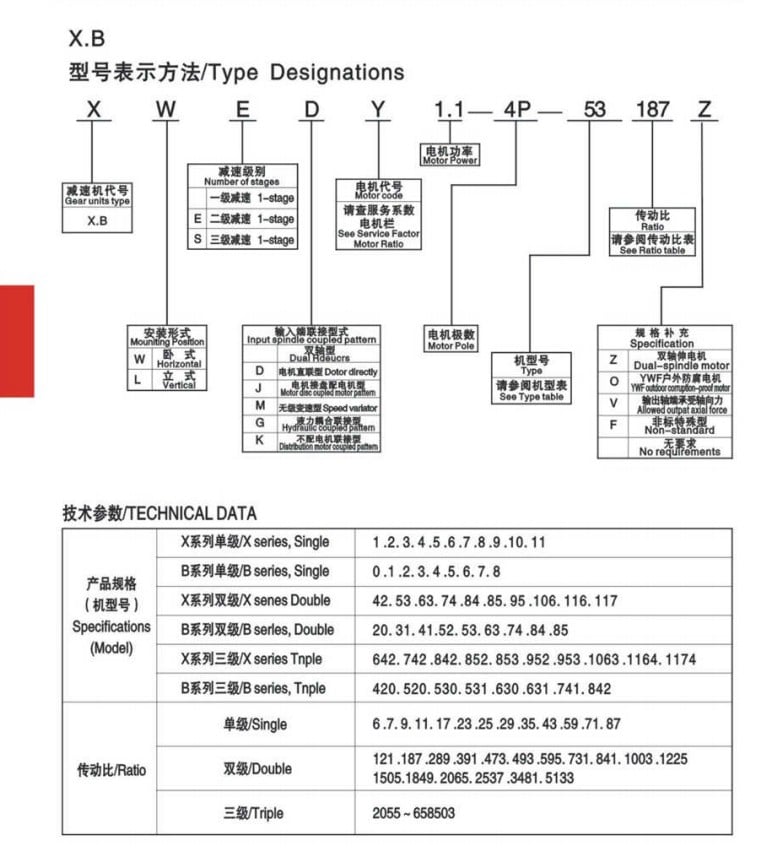

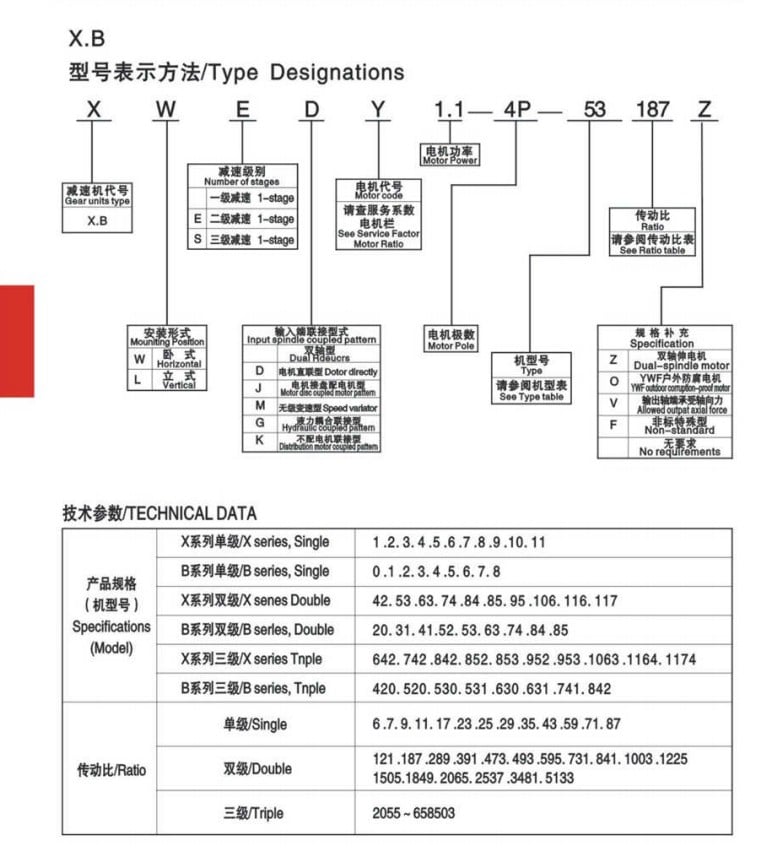

| SLXG Collection Shaft Mounted Reducer | X/B Sequence Cycloidal Reducer |

| SLR/SLF/SLK/SLS Series Helical Reducer |

Best China manufacturer & factory XB in Rawalpindi Pakistan cycloidal pin wheel speed gearbox variator drive power transmission cycloidal gearbox gear box marine engine with gearbox With high quality best price

our products are selling well in the American, European, South American and Asian markets. a specialized supplier of a full range of chains, sprockets, gears, gear racks, V-belts, couplings and reducers, pto shaft, agricultural gearboxes….

Overview

Quick Details

-

We designed, especially for our customers, a protective cone which is flexible and enables easier handling while coupling the PTO on the tractor or working machine. The flexible cone offers additional comfort when coupling the PTO, because you can get a good grip in the limited shaft space.

- Applicable Industries:

-

Manufacturing Plant, Machinery Repair Shops, Food & Beverage Factory, farms

BUILDING ON LEADERSHIP IN INNOVATION Our investments in research and development significantly exceed the industry average. This is a result of our distinctive culture of innovation.

- Place of Origin:Zhejiang, China

- Brand Name:

-

OEM

- Gearing Arrangement:

-

Cycloidal

- Output Torque:

-

4.5-34600N

- Input Speed:

-

1000-1800r/min

- Output Speed:

-

11-300r/min

- Type:

-

8000series

Supply Ability

- Supply Ability:

- 40000 Set/Sets per Year

Packaging & Our factory has obtained the certificate of China’s Farm Machinery Products Quality Authentication promulgated by the Farm Machinery Products Quality Authentication Centre of China. Delivery

- Packaging Details

- Standard wooden cases , or wooden pallet

- Port

- SHANGHAI PORT / NINGBO PORT

Online Customization

Product Description

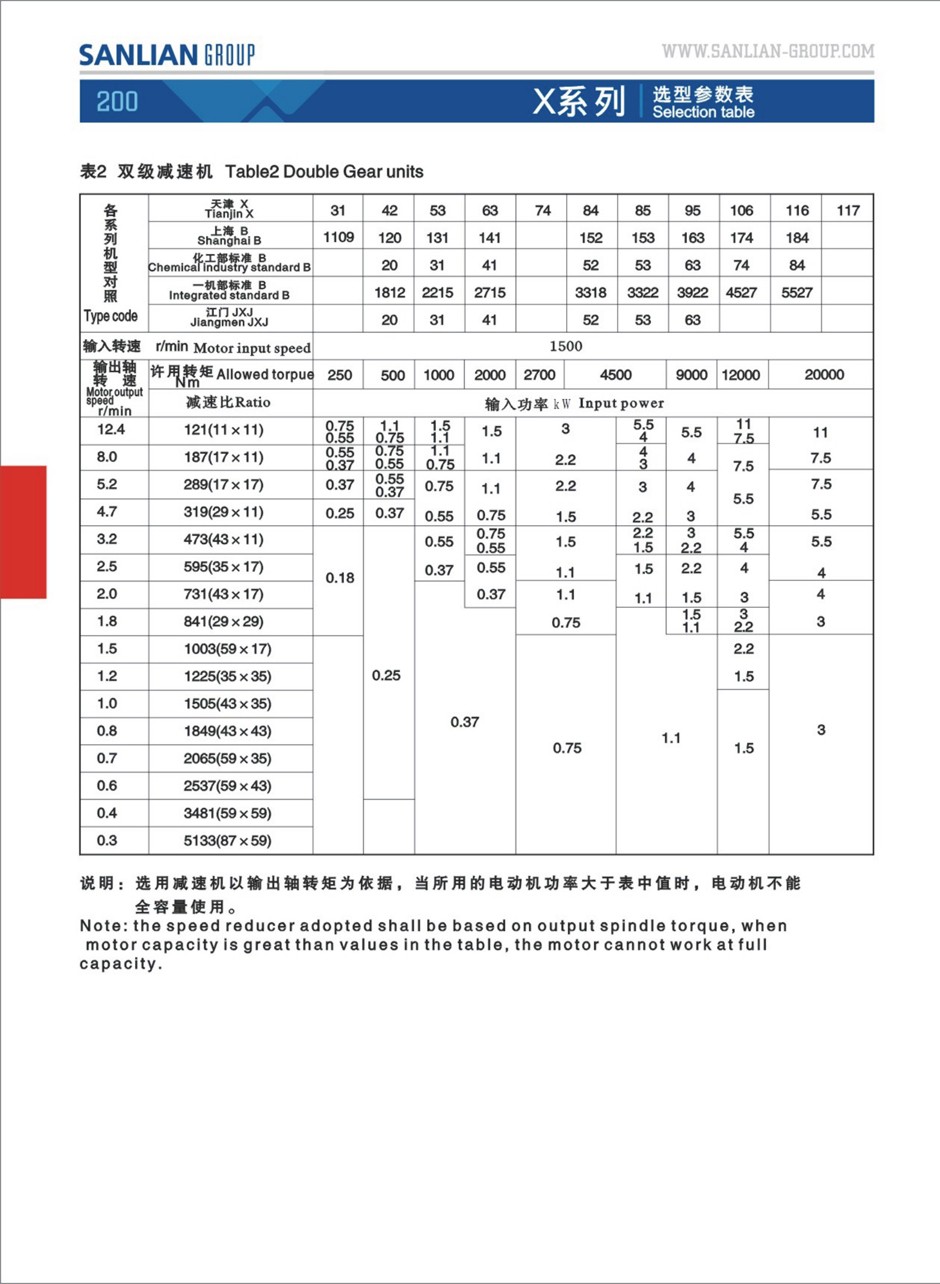

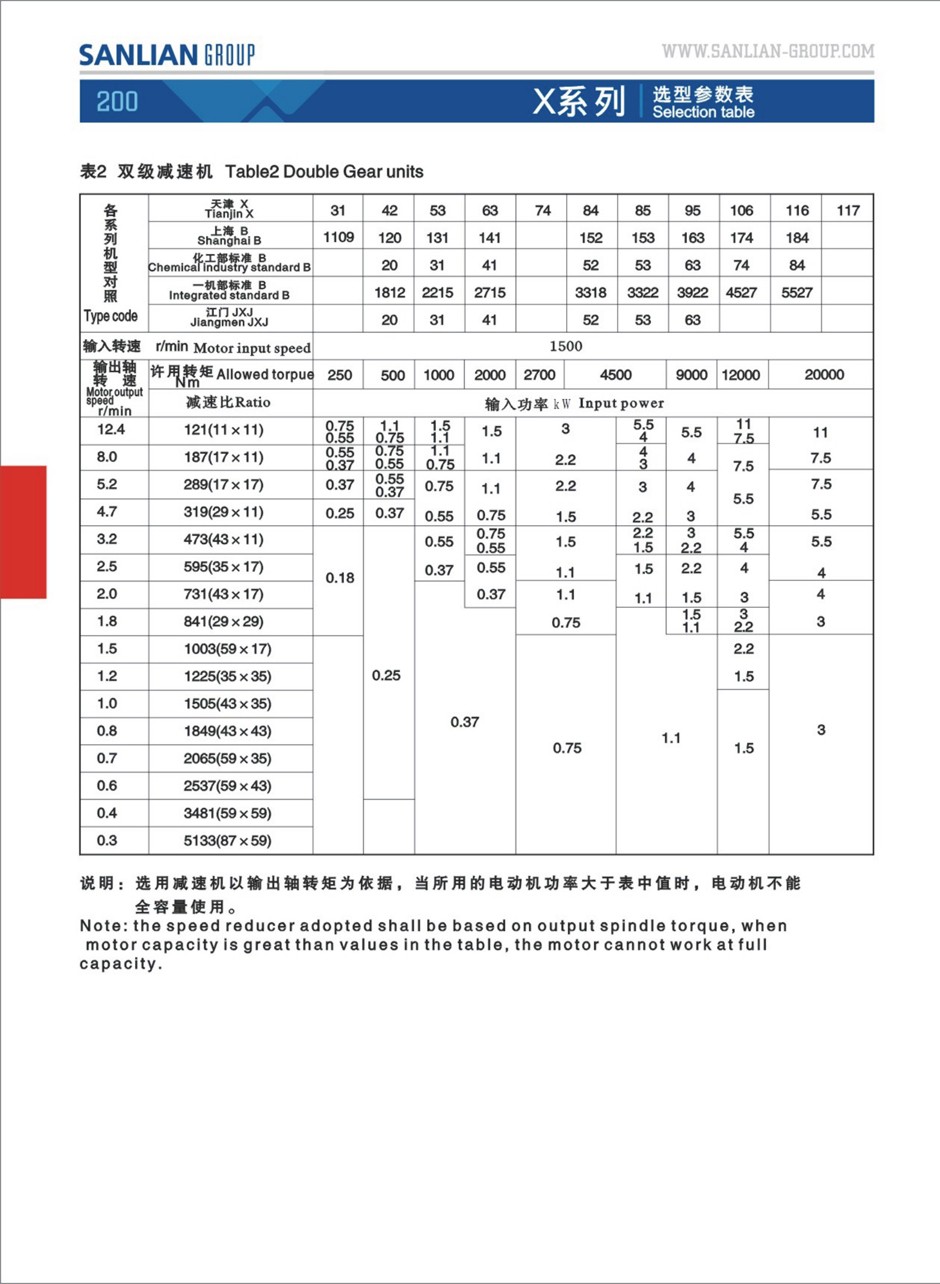

XB cycloidal pin wheel speed gearbox variator

Input Speed: 1000-1500rmp

Output Speed: 11-300rpm

Certification: ISO9001 CE Ex Power:0.09-132KW Warranty: 1Years

|

Product Name |

8000 series Cycloidal Pin Wheel Speed Reducer |

|

The Gear Material |

GCR15 |

|

The case Material |

Cast Iron |

|

Color |

Blue,Green, or Customized |

|

HS Code |

84834090 |

|

Model |

8115 |

|

Delivery time |

10-15days |

|

Brand |

TIANGOU |

Certifications

Trade Shows

Packaging & Shipping

Packing Details : Standard carton/Pallet/Standard wooden case

Delivery Details : 15-30 working days upon payment

Company Information

other series product

| Precision Planetary gearbox | Robot RV gearbox speed reducer |

| Custom made Non-standard Gearbox | UDL Series Variator |

| PYZ Series Helical Tooth Shaft Mounted Reducer | 8000 Series Cycloidal Reducer |

| SLT Series Spiral Bevel Gearbox | SLSWL Series Worm Screw Jack |

| SLP Series Planetary Reducer | SLH/SLB Series High Power Reducer |

| NMRV Series Worm Reducer | BKM Series Helical-hypoid Reducer |

| SLRC Series Helical Reducer | SLSMR Series Shaft Mounted Reducer |

| SLXG Series Shaft Mounted Reducer | X/B Series Cycloidal Reducer |

| SLR/SLF/SLK/SLS Series Helical Reducer |

Related Products

Contact

B High Qualtiy series helical bevel gearbox right angle industrial gear units reducer gear box motor speed variator drive power transmission

In 2000, EPG took the direct in getting ISO14001 surroundings management certification and thereafter passed the inspection of cleanse production and recycling financial system, successful the title of “Zhejiang Eco-friendly Company”.

Overview

Fast Particulars

- Relevant Industries:

-

Creating Substance Retailers

- Gearing Arrangement:

-

Helical

- Output Torque:

-

470000Nm

- Input Velocity:

-

750-1500rpm

- Output Velocity:

-

1.seven~1200rpm

- Place of Origin:Zhejiang, China

- Model Identify:

-

OEM

- Certification:

-

ISO9001-2008

- Mount Situation:

-

Foot Mounted

- Bearing:

-

C&U

Offer Potential

- Provide Capability:

- 500 Unit/Units per Month

Packaging & Supply

- Packaging Details

- Standard wood circumstance

- Port

- Ningbo Port, Shanghai Port

-

Lead Time

: -

Quantity(Packing containers) 1 – one >1 Est. Time(times) 20 To be negotiated

Online Customization

Merchandise Description

B collection helical bevel gearbox right angle industrial gear models reducer gear box motor velocity variator drive electricity transmission

B sequence helical bevel gearboxe correct angle industrial gear units has the attributes of higher versatility,very good blend and heavy loading capacity, alongside with other merits such as effortless to attain numerous transmission ratios, higher effectiveness, reduced vibration and large permissible axis radial load.

one) Output velocity: one.7~1200r/min

2) Output torque: up to forty seven,000N.m

three) Motor power: 2.fifty two~5366kW

4) Mounted form: foot-mounted ,flange-mounted, axis mounted, shrink mounted

|

Merchandise Title |

B series helical bevel gearboxe proper angle industrial equipment models |

|

Housing Material |

HT 250 Solid Iron |

|

Equipment Material |

20CrMnTi |

|

Shaft Material |

20CrMnTi |

|

Gear Processing |

Grinding end by HOFLER Grinding Machines |

|

Color |

Customized |

|

Sound Check |

Bellow 65dB |

|

Warranty |

1 yr |

Organization information

Top quality manage

Packing

Packing Information : Standard carton/Pallet/Normal picket case

Shipping Details : 15-30 functioning days on payment

Supply

FAQ

Q1: What information must I inform you to confirm the merchandise?

A: Design/Size, Transmission Ratio, Shaft directions & Purchase quantity.

Q2: What can i do if I never know which 1 I need?

A: Never fear, Deliver as much details as you can, our crew will assist you locate the appropriate one you are searching for.

Q3: What is your product warranty period of time?

A:We supply a single year guarantee given that the vessel departure day remaining China.

If you have any question, pls truly feel cost-free to speak to us.

Speak to us