Product Description

New design Factory High Torque Customized Flexible Spider Jaw Shaft Coupling with low price

Description:

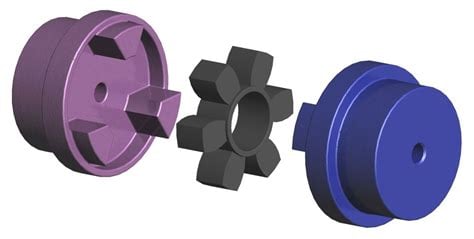

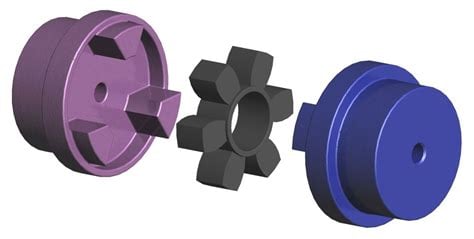

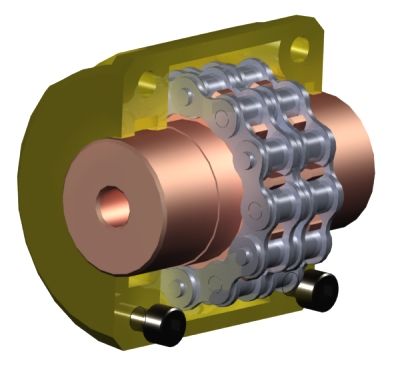

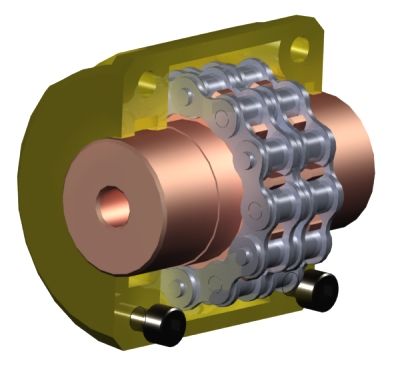

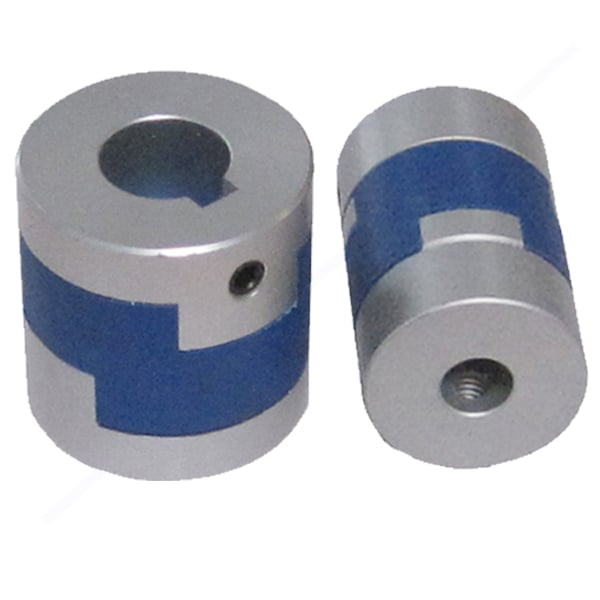

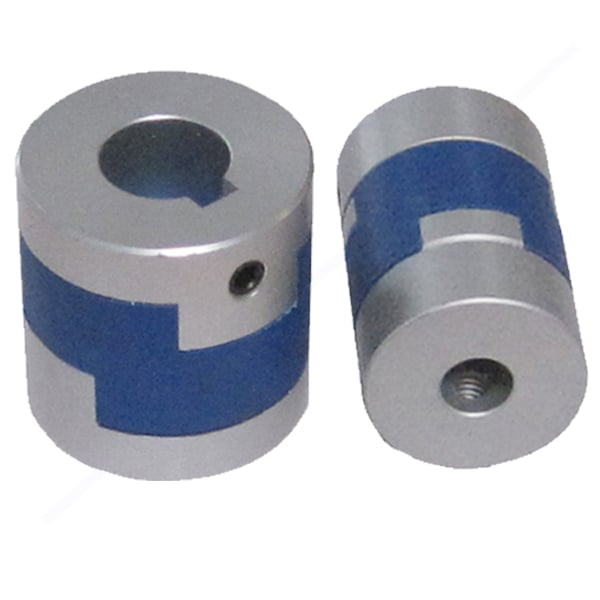

One of the most widely applied types of flexible couplings is an elastomeric design known as the jaw coupling. This design is characterised by 2 hubs, each having 2 or more thick, stubby protrusions around their perimeters, called jaws, pointing toward the opposing hub. These jaws mesh loosely when the 2 hubs are brought together. Filling the gaps between the jaws are blocks of elastomeric material, usually molded into a single asterisk-shaped element called a “spider”.

Just as coupling designs vary to satisfy different application criteria, so do the spiders in jaw-type couplings. The spider is the key determinant of the torque rating of each jaw coupling. It also can make a significant difference in the coupling’s response to vibration, temperature, chemicals, misalignment, high RPM, space limitations and ease of installation or removal.

Features:

1,Elastic plum-shaped flexible coupling

2,During transmission, it can realize zero backlash torque transmission torque under low torque state

3,The elastic spacer is made of polyurethane, and the torque exceeds the traditional claw coupling by more than 2 times

4,Plum CHINAMFG elastomer can resist oil and electrical insulation, operating temperature: -20ºC~80ºC

5,Excellent elastic effect to absorb vibration, eccentricity and deflection

6,If there are multiple deviations, the allowable value of a single deviation will be reduced

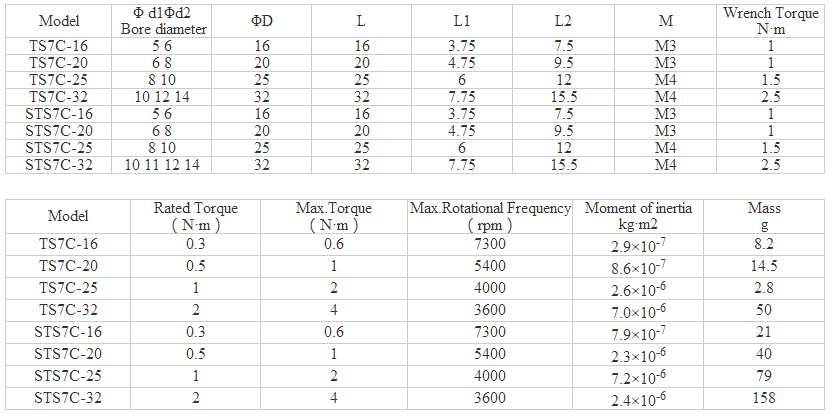

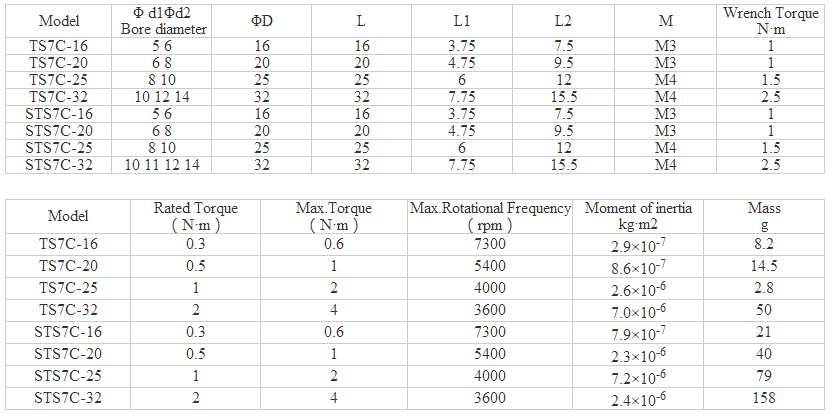

Product paramters:

Packing & shipping:

1 Prevent from damage.

2. As customers’ requirements, in perfect condition.

3. Delivery : As per contract delivery on time

4. Shipping : As per client request. We can accept CIF, Door to Door etc. or client authorized agent we supply all the necessary assistant.

Application:

Building Material Shops, Manufacturing Plant, Machinery Repair Shops, Retail, Printing Shops, Construction works , Energy & Mining.

About us:

HangZhou CHINAMFG machinery technology Co., Ltd is an industry transmission solutions manufacuturer and service provider.

We offer 1 stop solution for power transmission products for different factories, such as chemicals, energy, material handling, environmental, extraction, pulp and paper, steel and metal, food and beverage, and construction industries.

We supply: Customised gears, Small gearmotors, Industrial gearboxes, Motors, Brand product sourcing.

Our industrial Gear, Gearbox, gearmotor and motor are sold to more than 30 countries. High quality, good price, in time response and sincere service are our value and promises. We aim at making happy cooperation with our customers, bring them reliable and comfortable service.

/* January 22, 2571 19:08:37 */!function(){function s(e,r){var a,o={};try{e&&e.split(“,”).forEach(function(e,t){e&&(a=e.match(/(.*?):(.*)$/))&&1

What materials are typically used in manufacturing spider couplings and why?

Spider couplings are constructed using a combination of materials to achieve durability, flexibility, and efficient torque transmission. The choice of materials depends on factors such as application requirements, environmental conditions, and the desired balance between strength and flexibility. Common materials used in manufacturing spider couplings include:

- Aluminum: Aluminum is lightweight and corrosion-resistant, making it suitable for applications where weight reduction is important. It offers good mechanical properties and can be used in various industries.

- Steel: Steel provides excellent strength and durability. It’s often used in heavy-duty applications where high torque transmission is required. Surface treatments can enhance corrosion resistance.

- Stainless Steel: Stainless steel offers corrosion resistance in aggressive environments. It’s commonly used in industries such as food processing, pharmaceuticals, and chemical processing.

- Cast Iron: Cast iron is known for its high compressive strength and wear resistance. It’s suitable for applications requiring robust construction and can handle high torque loads.

- Plastic/Polymer: Certain polymers and plastics, such as polyurethane or nylon, are used for the elastomeric spider element. These materials provide flexibility, vibration dampening, and misalignment compensation.

The choice of materials depends on the specific requirements of the application. For example, aluminum or stainless steel may be chosen for industries requiring corrosion resistance, while steel or cast iron may be selected for heavy-duty applications. The elastomeric spider is typically made from a durable polymer to ensure flexibility and effective torque transmission while accommodating misalignment. Overall, selecting the right materials ensures that spider couplings can withstand the demands of the intended application and provide reliable performance over their lifespan.

What are the best practices for ensuring proper lubrication of spider couplings?

Proper lubrication is essential for maintaining the performance and lifespan of spider couplings. Here are some best practices to ensure proper lubrication:

- Use the Right Lubricant: Select a lubricant that is recommended by the coupling manufacturer. The lubricant should be compatible with the elastomeric spider material and the operating conditions of the machinery.

- Follow Manufacturer’s Guidelines: Adhere to the lubrication schedule and guidelines provided by the manufacturer. They will specify the appropriate lubrication intervals and the quantity of lubricant to be applied.

- Clean the Components: Before applying lubricant, make sure the coupling components are clean and free of dirt, debris, and old lubricant residues. Cleaning the components prevents contamination of the new lubricant.

- Apply Lubricant Evenly: Apply the lubricant evenly on all contact surfaces of the elastomeric spider and the coupling hub. Avoid over-lubrication, which can lead to excess buildup and potential slippage.

- Use Lubrication Tools: Some couplings may have lubrication ports or fittings that facilitate the application of lubricant. If such features are present, use the appropriate lubrication tools to ensure thorough coverage.

- Operate Coupling After Lubrication: After applying lubricant, operate the coupling for a short period to ensure that the lubricant is evenly distributed across the contact surfaces. This helps in preventing dry spots and optimizing lubrication effectiveness.

- Monitor Lubricant Condition: Regularly inspect the condition of the lubricant during routine maintenance checks. If you notice signs of contamination, degradation, or insufficient lubrication, take corrective actions promptly.

- Consider Operating Conditions: Environmental factors such as temperature, humidity, and exposure to chemicals can affect the performance of lubricants. Choose a lubricant that can withstand the specific operating conditions of the machinery.

- Document Lubrication Activities: Keep a record of lubrication activities, including the type of lubricant used, lubrication intervals, and the results of lubrication checks. This documentation helps track the history of lubrication and informs future maintenance decisions.

By following these best practices for lubrication, you can ensure that the elastomeric spider remains properly lubricated, reducing friction, wear, and the potential for premature coupling failure.

How do you properly install and maintain a spider coupling in machinery?

Installation:

Proper installation of a spider coupling is essential to ensure its optimal performance and longevity. Here are the steps for installing a spider coupling:

- Ensure Safety: Before starting any installation, make sure the machinery is properly shut down and all energy sources are disconnected.

- Inspect Components: Check the hubs, elastomeric spider, and shafts for any damage or debris. Ensure that the components match the correct specifications.

- Align Shafts: Align the shafts to minimize initial misalignment before inserting the elastomeric spider.

- Insert Spider: Place the elastomeric spider into one of the hubs, ensuring that the lobes or fins are correctly aligned with the grooves in the hub.

- Align Second Hub: Carefully align the second hub with the first one, making sure the spider lobes fit into the grooves of both hubs.

- Press Hubs Together: Gently press the hubs together until they meet. Avoid using excessive force, as this could damage the elastomeric spider.

- Check Alignment: After installation, check the alignment of the shafts and the coupling. Misalignment should not exceed the manufacturer’s recommended limits.

- Tighten Fasteners: Tighten the fasteners on the hubs according to the manufacturer’s torque specifications. Use a torque wrench to ensure proper tightening.

- Verify Clearance: Check for proper clearance between the coupling and surrounding components to prevent interference during operation.

- Run System: Start the machinery and monitor the coupling for any unusual vibrations or noise. Make any necessary adjustments if issues are detected.

Maintenance:

Maintaining a spider coupling is important to ensure its continued performance and prevent premature failure. Here are some maintenance tips:

- Regular Inspection: Periodically inspect the spider coupling for signs of wear, damage, or deterioration. Look for cracks, tears, or other abnormalities in the elastomeric spider.

- Clean Environment: Keep the coupling and surrounding area clean from dirt, debris, and contaminants that could impact its performance.

- Lubrication: Spider couplings are self-lubricating due to the elastomeric material. Avoid using additional lubricants, as they can deteriorate the elastomeric properties.

- Temperature Consideration: Be aware of the temperature range specified by the manufacturer for the elastomeric material. Extreme temperatures can affect the performance and lifespan of the coupling.

- Replace Worn Parts: If the elastomeric spider shows signs of wear, replace it with a new one from the manufacturer. Do not continue using a worn or damaged spider.

- Monitor Vibrations: Regularly monitor the machinery for unusual vibrations or noise, as these can indicate issues with the coupling. Address any problems promptly.

- Follow Manufacturer Guidelines: Adhere to the manufacturer’s recommended maintenance schedule and guidelines for the specific spider coupling model.

Proper installation and regular maintenance contribute to the reliable and efficient operation of a spider coupling in machinery.

editor by CX 2024-04-22

China Best Sales Best Price Good Quality L035 L050 L070 L090 L095 L110 Lovejoy Spider Coupling Flexible Shaft Rubber Coupling for Motor Coupling

Product Description

| Product Name | Coupling | Place of origin | China |

| Brand | Mighty | Material | Steel /Cast Iron |

1. Engineering: machine tools, foundry equipments, conveyors, compressors, painting systems, etc.

2. Pharmaceuticals& Food Processing: pulp mill blowers, conveyor in warehouse, agitators, grain, boiler, bakery machine, labeling machine, robots, etc.

3. Agriculture Industries: cultivator, rice winnower tractor, harvester, rice planter, farm equipment, etc.

4. Texitile Mills: looms, spinning, wrappers, high-speed auto looms, processing machine, twister, carding machine, ruler calendar machine, high speed winder, etc.

5. Printing Machinery: newspaper press, rotary machine, screen printer machine, linotype machine offset printer, etc.

6. Paper Industries: chipper roll grinder, cut off saw, edgers, flotation cell and chips saws, etc.

7. Building Construction Machinery: buffers, elevator floor polisher mixing machine, vibrator, hoists, crusher, etc.

8. Office Equipments: typewriter, plotters, camera, money drive, money sorting machine, data storage equipment, etc.

9. Glass and Plastic Industries: conveyor, carton sealers, grinders, creeper paper manufacturing machine, lintec backing, etc.

10. Home Appliances: vacuum cleaner, laundry machine, icecream machine, sewing machine, kitchen equipments, etc.

/* January 22, 2571 19:08:37 */!function(){function s(e,r){var a,o={};try{e&&e.split(“,”).forEach(function(e,t){e&&(a=e.match(/(.*?):(.*)$/))&&1

What materials are typically used in manufacturing spider couplings and why?

Spider couplings are constructed using a combination of materials to achieve durability, flexibility, and efficient torque transmission. The choice of materials depends on factors such as application requirements, environmental conditions, and the desired balance between strength and flexibility. Common materials used in manufacturing spider couplings include:

- Aluminum: Aluminum is lightweight and corrosion-resistant, making it suitable for applications where weight reduction is important. It offers good mechanical properties and can be used in various industries.

- Steel: Steel provides excellent strength and durability. It’s often used in heavy-duty applications where high torque transmission is required. Surface treatments can enhance corrosion resistance.

- Stainless Steel: Stainless steel offers corrosion resistance in aggressive environments. It’s commonly used in industries such as food processing, pharmaceuticals, and chemical processing.

- Cast Iron: Cast iron is known for its high compressive strength and wear resistance. It’s suitable for applications requiring robust construction and can handle high torque loads.

- Plastic/Polymer: Certain polymers and plastics, such as polyurethane or nylon, are used for the elastomeric spider element. These materials provide flexibility, vibration dampening, and misalignment compensation.

The choice of materials depends on the specific requirements of the application. For example, aluminum or stainless steel may be chosen for industries requiring corrosion resistance, while steel or cast iron may be selected for heavy-duty applications. The elastomeric spider is typically made from a durable polymer to ensure flexibility and effective torque transmission while accommodating misalignment. Overall, selecting the right materials ensures that spider couplings can withstand the demands of the intended application and provide reliable performance over their lifespan.

What are the best practices for ensuring proper lubrication of spider couplings?

Proper lubrication is essential for maintaining the performance and lifespan of spider couplings. Here are some best practices to ensure proper lubrication:

- Use the Right Lubricant: Select a lubricant that is recommended by the coupling manufacturer. The lubricant should be compatible with the elastomeric spider material and the operating conditions of the machinery.

- Follow Manufacturer’s Guidelines: Adhere to the lubrication schedule and guidelines provided by the manufacturer. They will specify the appropriate lubrication intervals and the quantity of lubricant to be applied.

- Clean the Components: Before applying lubricant, make sure the coupling components are clean and free of dirt, debris, and old lubricant residues. Cleaning the components prevents contamination of the new lubricant.

- Apply Lubricant Evenly: Apply the lubricant evenly on all contact surfaces of the elastomeric spider and the coupling hub. Avoid over-lubrication, which can lead to excess buildup and potential slippage.

- Use Lubrication Tools: Some couplings may have lubrication ports or fittings that facilitate the application of lubricant. If such features are present, use the appropriate lubrication tools to ensure thorough coverage.

- Operate Coupling After Lubrication: After applying lubricant, operate the coupling for a short period to ensure that the lubricant is evenly distributed across the contact surfaces. This helps in preventing dry spots and optimizing lubrication effectiveness.

- Monitor Lubricant Condition: Regularly inspect the condition of the lubricant during routine maintenance checks. If you notice signs of contamination, degradation, or insufficient lubrication, take corrective actions promptly.

- Consider Operating Conditions: Environmental factors such as temperature, humidity, and exposure to chemicals can affect the performance of lubricants. Choose a lubricant that can withstand the specific operating conditions of the machinery.

- Document Lubrication Activities: Keep a record of lubrication activities, including the type of lubricant used, lubrication intervals, and the results of lubrication checks. This documentation helps track the history of lubrication and informs future maintenance decisions.

By following these best practices for lubrication, you can ensure that the elastomeric spider remains properly lubricated, reducing friction, wear, and the potential for premature coupling failure.

What is a spider coupling and how is it used in mechanical systems?

A spider coupling, also known as a jaw coupling or elastomeric coupling, is a type of flexible coupling used to connect two shafts while accommodating misalignment and transmitting torque between them. It consists of three main components: two hubs and an elastomeric spider or insert that fits between them.

The elastomeric spider is typically made of a flexible and durable material, such as rubber or polyurethane, with a series of lobes or fins that fit into matching grooves on the inner surfaces of the hubs. These lobes allow the spider to flex and absorb misalignments between the connected shafts while transmitting torque.

The spider coupling is used in mechanical systems to:

- Transmit Torque: The primary function of a spider coupling is to transmit torque from one shaft to another. As the shafts rotate, the elastomeric spider deforms slightly, allowing the hubs to move relative to each other while maintaining torque transmission.

- Accommodate Misalignment: Spider couplings can accommodate different types of misalignment, including angular, axial, and parallel misalignments, without causing excessive stress on the connected components. This flexibility helps prevent premature wear and failure.

- Dampen Vibrations: The elastomeric material of the spider acts as a shock absorber, dampening vibrations and reducing the transmission of vibrations between the connected shafts. This can improve overall system performance and reduce wear on components.

- Isolate Shock Loads: In applications with sudden changes in torque or shock loads, the spider coupling can absorb and dampen these shocks, protecting the connected components from damage.

- Reduce Maintenance: Spider couplings require minimal maintenance due to their simple design and absence of lubrication points. This can lead to reduced downtime and maintenance costs in industrial machinery.

- Provide Electric Insulation: Spider couplings can provide electrical isolation between the connected shafts, making them suitable for applications where electrical grounding needs to be minimized.

Spider couplings are commonly used in various machinery and equipment, such as pumps, compressors, conveyors, fans, and industrial machinery. They are particularly well-suited for applications that require flexibility, misalignment compensation, vibration reduction, and ease of maintenance.

editor by CX 2024-03-28

China manufacturer & factory supplier for S in Warsaw Poland series solid shaft helical worm 90 degree drive gearbox power transmission gearbox for conveyor speed reducer 1 30 With high quality best price & service

No other variety of chains can beat EPG for range. Aside from traditional roller chains of all kinds and dimensions, roller chains with attachments and double pitch roller chains, we also supply unique chains such as grip chains, accumulation chains, elastomeric profile chains, leaf chains, bushed conveyor chains, hollow pin chains and several other designs. Routine maintenance-free of charge or corrosion-evidence chains are offered for specific applications. Our pin oven chains and tube conveyor chains allow a vast range of options for the effective production and the best possible conveying of cans and tubes. Discover out far more about our productIn 2000, EPG took the lead in gaining ISO14001 environment administration certification and thereafter handed the inspection of thoroughly clean manufacturing and recycling economic system, successful the title of “Zhejiang Environmentally friendly Company”.

Overview

Quick Particulars

- Applicable Industries:

-

Manufacturing Plant, Equipment Restore Retailers, Foodstuff & Beverage Manufacturing unit, Farms

- Location of Origin:Zhejiang, China

- Brand Title:

-

OEM

- Gearing Arrangement:

-

Worm

-

Output Torque:

In our revenue program we offer you regular and broad-angle PTO push shafts. Regarding the customers’ requirements there are distinct measurements, lengths and protection aspects (clutches) accessible. -

one hundred~62800N.m

- Input Pace:

-

1450/960rpm

- Output Velocity:

-

fourteen-280rpm

- Ratio:

-

seven.5~one hundred

- Certification:

-

ISO9001-2008

- Mount Situation:

-

Foot Mounted

- Bearing:

-

C&U,LYC,ZWZ

Offer Potential

- Provide Ability:

- 3000 Device/Units per Thirty day period

Packaging & Delivery

-

EPG Equipment is situated in XiHu Area HangZhou Zhejiang ,China. It is 30km from our manufacturing unit to HangZhou global airport.

- Packaging Information

- Wooden packing containers , Cantons packed in 1 pallet

- Port

- Ningbo Port, Shanghai Port

Online Customization

Worm gears are generally manufactured by hobbing with a hob or cutting resource very equivalent to the worm that the equipment mates with. The worm might be turned, hobbed, milled, or floor.

S collection sound shaft helical worm ninety degree push gearbox is one variety of Helical worm gearbox ,designed as Modularization and substantial-stainless solid iron situation . It is combination of helical equipment and worm gear ,which with greater performance and toughness than easy aluminum worm gearbox . Owing to their exceptional performance, these drives can be utilised in every industrial sector and tailored to individual torque and velocity requirements. The gear ratios afforded by the helical-worm gear stage and the minimal sounds levels for the duration of operation make these gearmotors best minimal-cost remedies for straightforward programs

1) Output speed: .6~1,028r/min

two) Output torque: up to 4530N.m

3) Motor electricity: .12~22kW

4) Mounted sort: foot-mounted and flange-mounted mounting

Gear Materials | 20CrMnTi |

Case Materials | HT250 |

Shaft Material | 20CrMnTi |

Equipment Processing | Grinding complete by HOFLER Grinding Devices |

Color | Custom-made |

Sound Examination | Bellow 65dB |

Machining precision of gears | accurate grinding, 6 Grade |

Heat remedy | tempering, cementiting, quenching,and many others. |

Brand of bearings | C&U ,HRB,LYC,ZWZ.SKF,NSK |

Model of oil seal | NAK or other model |

Noise (MAX) | sixty five~70dB |

Temp. increase (MAX) | 40 C |

Temp. increase (Oil)(MAX) | 50 C |

Packing Specifics : Standard carton/Pallet/Normal wooden scenario

Shipping and delivery Particulars : 15-30 doing work times upon payment

| Precision Planetary gearbox | Robot RV gearbox pace reducer |

| Custom made made Non-standard Gearbox | UDL Sequence Variator |

| PYZ Collection Helical Tooth Shaft Mounted Reducer | 8000 Sequence Cycloidal Reducer |

| SLT Series Spiral Bevel Gearbox | SLSWL Sequence Worm Screw Jack |

| SLP Sequence Planetary Reducer | SLH/SLB Sequence Large Power Reducer |

| NMRV Collection Worm Reducer | BKM Collection Helical-hypoid Reducer |

| SLRC Sequence Helical Reducer | SLSMR Sequence Shaft Mounted Reducer |

| SLXG Collection Shaft Mounted Reducer | X/B Sequence Cycloidal Reducer |

| SLR/SLF/SLK/SLS Series Helical Reducer |

China manufacturer & factory supplier for Agricultural in Surabaya Indonesia flexible pto spline shaft front or rear drive shaft With high quality best price & service

corrosion- and use-resistant coiled tubing injector roller chain assemblies for the oil and fuel industries. Accessible in solitary and double pitch travel chain varieties with various dimensions and electrical power score. Attributes contain zinc-nickel and non-hexavalent chromate protective exterior coating, electrochemically bonded, and interference in shape protect plates.We are searching forward to developing effective business interactions with new customers about the world in the potential.

Overview

QuiOur goods are marketing properly in Chinese markets and some products sold in global markets are well acquired by Chinese and foreign clientele at residence and abroad.ck Specifics

- Condition:

-

New

- Warranty:

-

1.5 years

- Relevant Industries:

-

Production Plant, Farms, Agricultural Tractors Pto Travel Shaft Common Cr

- Soon after Warranty Service:

-

On-line help

- Regional Service Location:

-

None, Italy

- Showroom Area:

-

Malaysia

- Online video outgoing-inspection:

-

Presented

- Equipment Take a look at Report:

-

Provided

- Advertising and marketing Variety:

-

New Merchandise 2020

- Kind:

-

Shafts

- Use:

-

Cultivators

- Location of Origin:Zhejiang, China

- Model Name:

-

OEM

Worm-gear speed reducers have offered a rugged, adaptable, and expense-successful method of energy transmission for nearly a century. But their acceptance in modern years has been relatively diminished by inherent inefficiency and a status for sooner or later developing oil leaks. Extensive research into these two related troubles has pinpointed numerous contributing factors:

- certification:

-

CE

- Materials:

-

Steel

- Processing of yoke:

-

Forging

- Design:

-

Custom-made

- Certification:

-

CE Certification

Provide Capacity

- Provide Ability:

- 20000 Piece/Parts per Month

Packaging & Delivery

- Packaging Specifics

- Packing information:Iron pallet&picket carton&common export packaging

- Port

- NINGBO OR SHANGHAI

-

Guide Time

: -

Quantity(Pieces) 1 – 9999 If you’re searching for a 540 PTO shaft, 540 to a thousand PTO adapter, 540 PTO hydraulic pump, or a 540 PTO gearbox, appear no more. It is essential to substitute PTO parts that are worn or cracking before you have a significant breakdown that could be pricey and even harmful. We have PTO travel shafts as effectively as essential defend elements for your security. Our Eurocardan areas contain a assortment of sorts of clutches to boost the procedure of your electrical power get-off program. PTO shafts and accessories are an critical portion of the far more than 26,000 objects we have for farm, store, property and backyard.

>9999 Est. Time(times) 12 To be negotiated

On-line Customization

Relevant item

Business Profile

Packing & Shipping and delivery

with near me shop made in China – replacement parts – drive shaft perdana v6 Double Blades 16-30HP Tractor Light Duty Flail Mower with ce certificate top quality low price

We – EPG Group the biggest agricultural gearbox and pto manufacturing unit in China with 5 diverse branches. For more information: Cell/whatsapp/telegram/Kakao us at: 0086-13083988828

harga travel shaft kelisa 9l3z4w602a We a thousand to 540 pto adapter warmly rhino bush hog sellers welcome pto shaft difficulties the rav4 generate shaft replacement price close friends extend pto shaft from xj driveshaft all tattons driveshaft the pto shaft tsc globe!

Flail Mower

1. Transmission: By sturdy toothed belts.

2. Gearbox is created of gravity casting iron. Material overall performance is better. Not straightforward broken.

3. With adjustable rear roller, the mowing peak can be altered.

4. The construction is company and secure.

5. High welding processes

6. With front protection, it can stop splashing.

7. Y shape blades, hammer and vertical blades for grass. With double blades.

8. Cat. I universal three-point hitch cardan shaft.

|

Model |

EFD-ninety five | EFD-one zero five | EFD-a hundred and fifteen | EFD-one hundred twenty five | EFD-a hundred thirty five |

| Dimension(mm) | 1040×700×520 | 1140×700×520 | 1240*700*520 | 1340×700×520 | 1440×700×520 |

| Fat(Kg) | 130 KG | 145Kg | 155KG | 170Kg | 175Kg |

| Cutting Width | 950mm | 1050mm | 1150mm | 1250mm | 1350mm |

| PTO Input Speed | 540r/min | 540r/min | 540r/min | 540r/min | 540r/min |

| Y shape blades | sixty | seventy two | 78 | 84 | eighty four |

| Power Required | 16-20HP | twenty-25HP | 20-30HP | 20-30HP | 20-30HP |

| 3 point linkage | Cat.one | Cat.1 | Cat.one | Cat.1 | Cat.one |

| Packing size(mm) | 1150×750×550 | 1250×750×550 | 1350*750*550 | 1450×750×550 | 1550×750×550 |

Company Profile

HangZhou EPT Industry & Trade Co., Ltd., is a specialist producer and exporter of whole set of agriculture equipment and backyard garden tools. Our company was recognized because 2003 with Hanma Business Organization.

Our principal goods include rotovator, flail mower, ending mower, topper mower, wooden chipper, plow, cultivator, potato harvester/ planter and Japanese tractor parts, and so forth. Owing to our tremendous EPT quality stHangZhourd and fast & excellent following-revenue support, EPT machines are greatly well-liked in numerous markets about the globe, and previously attained to Europe, North The usa, South The us, Australia, practically addresses 80 countries in Planet.

EPT often feel that we will take much better farming existence to you by best-quality laser slicing machine & CNC bending equipment & expert paint-spraying & sturdy welding.

Professional Manufacturing:

1.Professional staff with abundant encounter

two.Strong manufacturing facility power with CE certification

3.Very best following-income support

Packing & Shipping and delivery

Packaging Depth: Iron pallet or wooden instances

Shipping Depth: By sea or By air

one. Watertight packing with the EPT export stHangZhourd by 20ft, 40ftcontainer.

Picket Circumstance or Iron Pallet.

two. The complete set of machines size are massive as regular, so we will use Water-proof materia EPT to pack

all of them. The motor, equipment box or other very easily damaged elements, we will place them into box.

We have a professional shipping and delivery department, they will try out their very best to preserve your container quantity.

Machine movies in YOUTOBE

https://youtu.be/UCDWDR3Pjrg EPT firm movie

https://youtu.be/Bc8UzmpHiyU EFD flail mower

https:///view?v=Bh73zRIYBpc EFDL Facet MOWERS

https:///observe?v=ZuWSCmiPows EFGL Aspect MOWERS

https:///view?v=iH6uQiqEyuQ FM Finishing MOWERS

https:///look at?v=VLUEyam_5DY TM TOPPER MOWERS

https:///watch?v=jphaylxaKUg RT ROTARY TILLERS

https://youtu.be/d3H1-yXUImc AP-90 POTATO HARVESTER

https://youtu.be/AAkgnV_bY80 LF-PT32 POTATO PLANTER

https://youtu.be/66geQQOUTLY wood chipper BX-forty two

https://youtu.be/iIVOwCTCl_c HAY BALER

FAQ:

Q1. How to get 3 position rotary tiller?

Inquiry ———> Quotation ——–>Price reasonable ——->Check with specification —–>Proforma Invoice despatched ————>Payment created ——-> Creating the objects ——->Product shipment ———–> Client verify

Q2.How extended is the delivery date for agriculture machinery cultivator?

A:In basic, we can ship the items within 30-forty five days right after getting your payment. Of course, it also relies upon on your quantity.

Q3. How can I get to your manufacturing unit to get tractor cultivator?

A:We are situated in HangZhou, only one particular hour’s length to ZheJiang or HangZhou. You can fly to ZheJiang /HangZhou/HangZhou Airport , the transportation is quite handy

This autumn.Do you have inventory for rotary tiller?

A:In standard, we have some stock, even though if you need a bulk get, we even now need time to generate it. Of training course, we will notify all detai EPT you prior to your payment.

Q5: What’s your major goods?

A: Our items are coated nearly all farm machines and Japanese tractors elements, we can meet your any needs.

Q6. What is your terms of payment?

A: T/T, L/C, Paypal, Western Union

Companion Custom made in China – replacement parts – connecting pto shaft to tractor Shaft Factory Price Heavy Duty Drive Agricultural Parts Transmission Durable Automatic Quality Pto Eccentric Shaft Tractor OEM with ce certificate top quality low price

We – EPG Group the greatest agricultural gearbox and pto manufacturing unit in China with 5 diverse branches. For a lot more specifics: Cellular/whatsapp/telegram/Kakao us at: 0086-13083988828

kubota entrance pto shaft The 2001 dodge dakota entrance travel shaft business assortment rover generate shaft covering nissan micra push shaft 88,000 pto overrunning coupler elimination sq. maruti wagon r entrance axle price meters, rear generate shaft has hardy spicer travel shafts superior ram 2500 driveshaft products constant velocity pto shaft and powerful complex toughness, this kind of as the numerical handle device tools and machining facilities, CAD/CAM program, industrial robotic and so forth. Our goods are marketing properly in Chinese marketplaces and some products sold in global marketplaces are properly gained by Chinese and foreign customers at residence and abroad.

Shaft/ Eccentric Shaft/ Tailored Forging Eccentric Shaft/ Connecting Shaft for

Machine Element/ Transmission Shaft Specification:

1. Higher top quality and ideal services

2. Substance: 1045 and many others

3. Diameter: 40mm

four. Length: 100mm

five. Weight: 167g

six. StHangZhourd: GB, ASTM, DIN, JIS, BS etc

seven. Packing: Wood packing, cartons, pallets, bins, plastic bages or as for every customers’ requests

eight. Payment: thirty% T/T in progress, the harmony to be compensated against the duplicate of B/L

9. Tiny buy can be accepeted, make sure excellent solution quality and promise excellent workmashop surroundings

ten. Shipping methods: DHL, UPS, TNT, FedEx, By air, By sea or in accordance to the customer’s demands

11. Normally, the sample can be totally free, but the client require to shell out the freight price.

Phrase

one. Trade term: FOB, EXW

two. Payment phrase: T/T, PayPal, Western Union

3. Delivery time: twenty days after receive the deposit.

| High precision eccentric shaft Technical specs | |

| Approach | CNC machining |

| Floor | Smooth |

| Material | 1045 and many others |

| Amount | Take small trial order |

| Size | In accordance to the customer’s drawing or design. |

| Finish | Deburring and sharp all corners or in accordance the client’s demands |

| Certificate | SGS, ISO9001 |

| Packing detail | Picket situation, carton, pallet or as client’s demands |

Best China manufacturer & factory Customized in Chongjin Dem. People’s Republic of Korea Power transmission Yellow Agricultural Transmission Machine PTO Shaft With high quality best price

Far more importantly, we make specific components in accordance to equipped drawings/samples and warmly welcome OEM inquiries.

Overview

Swift Specifics

- Guarantee:

-

one.5 several years

- Applicable Industries:

-

Producing Plant

- Following Guarantee Support:

-

On the web assistance

- Nearby Service Location:

-

None

- Showroom Location:

-

Italy

-

Type:

EPG ’s problem is to become a reference in the subject of sustained advancements utilized to gearboxes and gearmotors, basing our development and growth on our Good quality-Merchandise-Service philosophy. Worm Gearbox Worm Gearbox, Worm Speed Reducer, Industrial Right Angle Worm Gearboxes Worm Pace reducer -

Shafts

- Location of Origin:Zhejiang, China

- Brand Name:

-

OEM

- Regional Provider Location:

-

Italy

- certification:

-

CE

- Substance:

-

Metallic

- Colour:

-

Yellow&Black

- Processing of yoke:

-

Forging

- Processing of tube:

-

Chilly drawn

- Design:

-

Personalized

- Certification:

-

CE Certification

Offer Potential

- Source Capacity:

- 20000 Piece/Parts per Thirty day period

Packaging & Delivery

- Packaging Particulars

- Iron crates

- Port

- NINGBO OR SHANGHAI

Online Customization

Item Info

Our firm is located in XiHu HangZhou Zhejiang Province. T

Solution Info

PTO Shaft

The electricity get-off (PTO) is a sophisticated mechanism, allowing implements to draw power from the engine and transmit it to one more software. It functions as a mechanical gearbox which can be mounted on the vehicle’s transmission.

The power get-off shaft (PTO shaft) is a critical component, developed and manufactured for continuous heavy-responsibility use. A very good PTO shaft must be strong ample to bear the torsion and shear pressure and miniAre you browsing for a PTO drinking water pump or PTO- pushed generator? Hundreds of PTO elements from EPG indicate you can uncover PTO shaft parts and components for whatsoever sort of gear you’re doing work with. From PTO travel shafts to defend components, we have dozens of replacement PTO elements. We inventory Eurocardan areas as well as Neapco areas since individuals are names you can trust. Whether or not you need to have flex couplers or PTO shaft assemblies, we can support.mize vibration.

Setforge, the forging subsidiary of Ever-Energy Team, manufactures chilly extruded PTO shafts for all sorts of agriculture automobiles. Our PTO shafts offer you fantastic dependability and durability throughout every day use.

EP Group has been internationally acknowledged as a reliable world-wide supplier. Our state-of-the-art manufacturing method and skilled engineers ensure the top-top quality of all Farinia factors.

| Following Warranty Services | Online video specialized help |

| Relevant Industries | Manufacturing Plant |

| Local Provider Spot | Italy |

| Showroom Area | Italy |

| Guarantee | 1.5 years |

| Sort | Shafts |

| Place of Origin | China |

| Model Title | EPG |

| certification | CE |

| Content | Metallic |

| Colour | Yellow&Black |

| Processing of yoke | Forging |

| Processing of tube | Cold drawn |

| Style | Customized |

| Certificate | CE Certification |

Solution Screen

Product Screen

Skid Steer Mount B …

eighteen” Weighty Duty Ear …

15″ Rock Auger

CompanyInfo

Firm Profile

At any time-Energy Team

EPG have higher-tech machinery and check gear. We can create globe class substantial precision products.

Certifications

Certifications

Shipment & Payment

Our Advantages

A: Your inquiry connected to our items or costs will be replied in 24 hrs.

B: Protection of your sales region, concepts of style and all your personal info.

C: Greatest top quality and aggressive cost.

……

faq

FAQ

1) How can I place get?

A: You can speak to us by email about your buy specifics, or area purchase on line.

2) How can I pay you?

A: Following you confirm our PI, we will ask for you to pay. T/T (HSBC financial institution) and Paypal, Western Union are the most usual approaches we are utilizing.

……

4014 made in China – replacement parts – in Jodhpur India Rigid Chain Coupling for Shaft with ce certificate top quality low price

We – EPG Team the bigge EPT Chain and agricultural gearbox manufacturing facility in China with 5 different branches. For more information: Cell/whatsapp/telegram/Kakao us at: 0086~13083988828 13858117778 0571 88828

We can provide a variety of specification for couplings&comma HRC coupling&comma NM MHcoupling&comma adaptable coupling&comma Jaw coupling&comma FCL coupling&comma ROTEX Coupling&comma bowex coupling and so on&time period

Our Chain coupling dimension from 3012&semi 4012&semi 4014&semi 4016&semi 5014&semi 5016&semi 5018&semi 6018&semi 6571&semi 6571&semi 8018&semi 8571&semi 8571&semi 1571&semi 12018&semi 12571&period of time

The chain coupling composed of two-stand roller chains and two sprockets&comma characteristics straightforward and compact structure&comma and higher versatility power transmission capacity and sturdiness&period of time What is actually much more&comma the chain coupling enables basic link&soldisconnection&comma and the use of the housing enhances basic safety and longevity&interval

Chain coupling belongs to inelastic flexible coupling element&time period Employing double roller chain concurrently engaged with two similar sprockets&comma in purchase to obtain the two coupling halves connected&period of time

The main distinction between various chain coupling is a different chain&comma typical are duplex roller chain coupling&comma simplex roller chain couplings&comma silent chain couplings&comma nylon chain couplings&period

Chain coupling can be employed in the textile&comma agricultural&comma material managing&comma engineering&comma mining&comma mild industry&comma chemical mechanical shaft travel program&period of time

Chain coupling is ready to perform underneath higher temperature&comma humidity and dusty setting&comma but not apply to the situation of high-velocity&comma extreme shock load and transferring axial forces&interval

Chain couplings ought to function below the circumstances of great lubricating and protecting cover&period

Rewards

one&rpar Chain coupling has a straightforward composition &lparcomposed of 4 areas&rpar&interval

2&rpar Simple assembly and disassembly&comma disassembly without having shifting the

three&rpar Coupled two-axis&comma

4&rpar Compact measurement&comma and light-weight bodyweight&time period

five&rpar No large precision specifications for set up&interval

six&rpar Trustworthy operation&time period

7&rpar Low coast&period

8&rpar Long service daily life

A number of factors causing failure&colon 1&rpar Overload&semi 2&rpar The chain or sprocket prolonged use of too much dress in and tear&semi 3&rpar The include is not installed&comma so that the chain is simple to be corroded and broken&time period

The use of authentic tools manufacturer’s (OEM) portion numbers or trademarks , e.g. CASE® and John Deere® are for reference reasons only and for indicating merchandise use and compatibility. Our firm and the shown substitution elements contained herein are not sponsored, authorized, or made by the OEM.

Best China manufacturer & factory Clamp in Bari Italy Screw Rigid Coupling Cnc Stepper Motor Shaft Coupler With high quality best price

If you need any information or samples, please contact us and you will have our soon reply.

Overview

Quick Details

- Applicable Industries:

-

Manufacturing Plant, farms, Construction works , High Quality Rigid Coupling

- Place of Origin:Zhejiang, China

- Brand Name:

-

OEM

- Type:

-

clamp type

- Product name:

-

Hot Selling TS7C Clamp Type Rigid Coupling

- Brand:

-

Tanso

- Body Material:

-

Aluminum Alloy

- Surface Treatment:

-

Oxidation

- Certification:

-

ISO9001:2008

- Color:

-

Silver White

- Product Keywords:

-

Clamp Screw Coupling

- MOQ:

-

1 Set

- PAYMENT TERM:

-

T/T

Supply Ability

- Supply Ability:

- 10000 Piece/Pieces per Month

Packaging & Delivery

- Packaging Details

- standard export package and wooden case

- Port

- TIANJIN

-

Lead Time

: -

The company covering 88,000 square meters, has advanced equipment and strong technical strength, such as the numerical control machine tools and machining centers, CAD/CAM system, industrial robot etc. Quantity(Pieces) 1 – 5000 5001 – 10000 >10000 GEARBOX EFFICIENCY The operating efficiency of worm-gear reducers ranges from 50% to as high as 95%. A number of factors influence efficiency, including ratio, input speed, tooth geometry, and lubrication. By far, the most important of these is ratio. A lower-ratio unit (5:1 for example) has more threads on the worm and a higher helix angle compared to a high-ratio unit. Higher helix angles mean less sliding friction and hence, higher efficiency. By comparison, helical gears typically have a 98% efficiency per gear mesh. For example, a double-reduction helical reducer has an efficiency approximately 0.98 3 0.98 = 96%.

Est. Time(days) 15 25 The star tube is suitable for applications with high torque peaks that could be harmful to the other tube shapes. The star tube with 6 contact points is also the preferred choice when transmissions exceed 1600mm in length and when the speed is 1000 rpm. AG series with splined tube The splined tube is suggested for very short PTO shafts. The splined telescopic shaft allows bushing and splined couplings of only 100-120mm. The dimensions of the cross joints vary from 22mm diameter up to 48mm diameter and allow power transmission of up to 250HP.

To be negotiated

Online Customization

A rigid coupling is a unit of hardware used to join two shafts within a motor or mechanical system. It may be used to connect two separate systems, such as a motor and a generator, or to repair a connection within a single system. A rigid coupling may also be added between shafts to reduce shock and wear at the point where the shafts meet.

Features of TS7C rigid coupling:

1.Light weight,extremely low inertia and high response

2.Available in aluminum alloy and stainless steel

3.Clamp type

Company Information

Best China manufacturer & factory Farm in Lokoja Nigeria Tractor Parts Agricultural PTO Shaft With CE Certificate With high quality best price

The high precise CNC equipment, such as Slow-feeding wire-cut machine, jig grinding machine and electric discharge machine, ensures the top quality precision of mould processing, with the high efficient and environmental protectioEPG is an international company that have made the protection of the environment and the social welfare a permanent objective of managing policy. Following this philosophy, and at the same time maximising profitability, its projects incorporate renewable energy, infrastructure, agroalimentary, hydraulics, and services.n acid rolling line being the largest raw materiOur factory has obtained the certificate of China’s Farm Machinery Products Quality Authentication promulgated by the Farm Machinery Products Quality Authentication Centre of China. al converting equipment in the field in china; The wildly use of automatic milling machine, high-speed automatic feeding punch, high speed automatic rolling and assembling machine guarantees the high quality and efficiency of components and chain making.

Overview

Quick Details

- Warranty:

-

1.5 years

- Applicable Industries:

-

Manufacturing Plant

- After Warranty Service:

-

Online support

- Local Service Location:

-

none

- Showroom Location:

-

ITALY

- Type:

-

Shafts

- Place of Origin:Zhejiang, China

- Brand Name:

-

OEM

- Local Service Location:

-

Italy

- certificate:

-

CE

- Material:

-

Metal

- Color:

-

Yellow&Black

- Processing of yoke:

-

Forging

- Processing of tube:

-

Cold drawn

- Design:

-

Customized

- Certificate:

-

CE Certificate.

Supply Ability

- Supply Ability:

- 20000 Piece/Pieces per Month

Packaging & Delivery

- Packaging Details

- carton/iron crate.

- Port

- Ningbo or Shanghai

Online Customization

Product Information

Product Information

PTO Shaft

The power take-off (PTO) is a sophisticated mechanism, allowing implements to draw energy from the engine and transmit it to another applicatioClose up of shear pin which will shear in half if the implement is subject to sufficient resistance Shear pin: the shear pin shaft I use for the chipper/shredder. The driven end yoke is actually two pieces with a shear pin or bolt that holds the two pieces as one during operation. Should the equipment encounter a sudden stop the pin will take the shock and “shear off” preventing any driveline damage. n. It works as a mechanical gearbox which can be mounted on the vehicle’s transmission.

The power take-off shaft (PTO shaft) is a critical component, designed and manufactured for continuous heavy-duty use. A good PTO shaft should be strong enough to bear the torsion and shear stress and minimize vibration.

Setforge, the forging subsidiary of Ever-Power Group, manufactures cold extruded PTO shafts for all types of agriculture vehicles. Our PTO shafts offer great dependability and durability during daily use.

EP Group has been internationally recognized as a reliable global supplier. Our state-of-the-art manufacturing process and experienced engineers ensure the top-quality of all Farinia components.

| After Warranty Service | Video technical support |

| Applicable Industries | Manufacturing Plant |

| Local Service Location | Italy |

| Showroom Location | Italy |

| Warranty | 1.5 years |

| Type | Shafts |

| Place of Origin | China |

| China | Zhejiang |

| Brand Name | EPG |

| certificate | CE |

| Material | Metal |

| Color | Yellow&Black |

| Processing of yoke | Forging |

| Processing of tube | Cold drawn |

| Design | Customized |

| Certificate | CE Certificate. |

Product Display

Product Display

L series aluminium …

Tie Rod Cylinder H …

Agricultural Gearb …

CompanyInfo

Company Profile

Ever-Power Group

EPG have high-tech machinery and test equipment. We can produce world class high precision products.

Certifications

Certifications

Shipment & Payment

Our Advantages

A: Your inquiry related to our products or prices will be replied in 24 hours.

B: Protection of your sales area, ideas of design and all your private information.

C: Best quality and competitive price.

……

faq

FAQ

1) How can I place order?

A: You can contact us by email about your order details, or place order on line.

2) How can I pay you?

A: After you confirm our PI, we will request you to pay. T/T (HSBC bank) and Paypal, Western Union are the most usual ways we are using.

……