Product Description

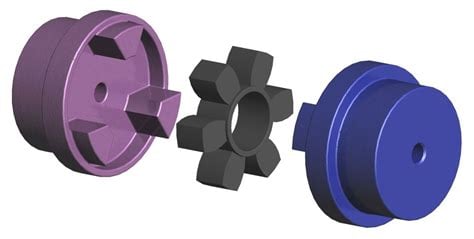

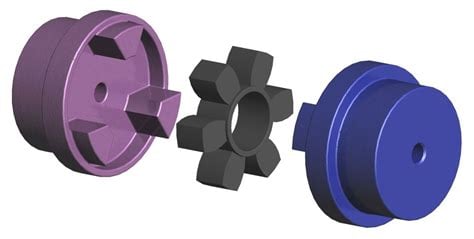

Gr65 CHINAMFG Coupling Spiders Shaft Connection 134*69*25 Screw Portable Air Compressor Coupling

Structure:Jaw / Spider Flexible or Rigid:Flexible

Standard or Nonstandard:Standard Material:PU, or others, PU

Brand Name:Y&F Place of Origin:HangZhou, China (Mainland)

Model Number:Elastic spider Item:spider coupling rubber

Color:Red color Size:GR65

MOQ:1 Pcs, also depend on you needs Specification:134*69*25

Supply Ability

Supply Ability:

3000 Piece/Pieces per Month

Packaging & Delivery

Packaging Details

In standard export packing:suche as carton, plastic bags etc.

HangZhou,China

Lead Time :

In 3-7 days or according to your orders

|

Place of Origin |

HangZhou, China (Mainland) |

|

Brand Name |

YNF/Y&F |

|

Property |

High/low temperature resistance, oil and fuel resistance, weathering resistance, O zone resistance etc. |

|

Shape |

According to your requirement. |

|

Color |

Red color |

|

Material |

Jaw,Spider,Rubber |

|

Delivery |

Within 10 days after payment |

|

Packing |

Plastic bag & carton box or according to your requirements. |

|

Application |

Excavator/Digger |

Why choose us:

Quality Controll

Competitive price

OEM Service

Experience more than 20 years’ experience

Wholesaler We supply a wide range of spare parts for excavators

Main products:

Seal Series:

arm cylinder seal kit, Boom cylinder seal kit, Bucket cylinder seal kit, main pump seal kit, travel motor seal kit,

swing motor seal kit, control valve seal kit, center joint seal kit, track adjust seal kit, bushings,

floating seals, o-ring box, pusher, etc.

Engine parts:

cylinder heads, cylinder blocks, crankshafts, camshafts, connecting rods, water pumps, turbo chargers,

engine assys, fan blades, main bearing and connecting rod bearings, pistons, piston rings, liner kits, etc.

Hydraulic parts:

hydraulic cylinder assembly, gear pump assembly, hydraulic pump assembly, travel motor assembly, final drive assembly, swing motor assembly,

main valve assembly, service valves, gasket kits, etc.

Electric Parts:

solenoid valves, water sensors, pressure sensors, throttle motors, stop solenoid, controllers, monitors, etc.

Other Parts:

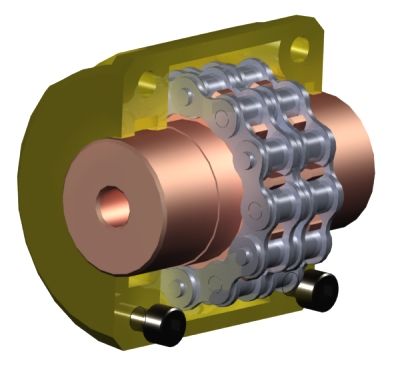

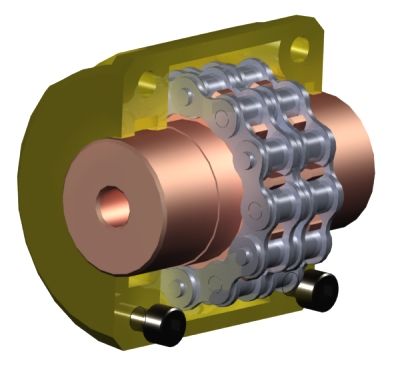

seal kits, bushings, floating seals, o-ring box, pushers, couplings, engine cushions, bearings, gears, fuel filter

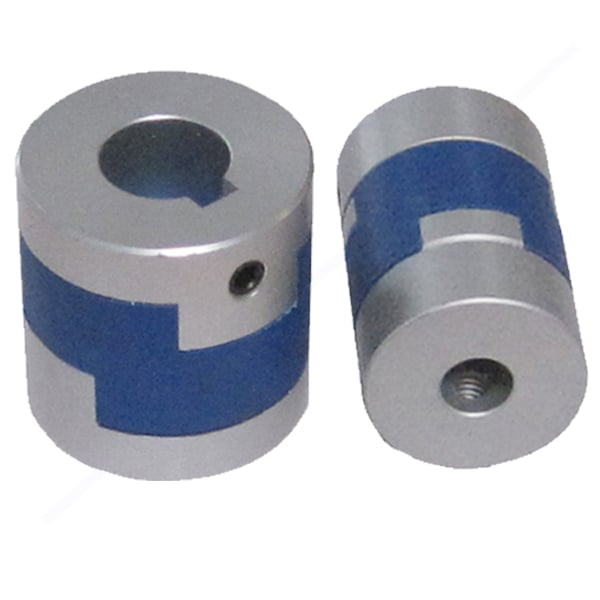

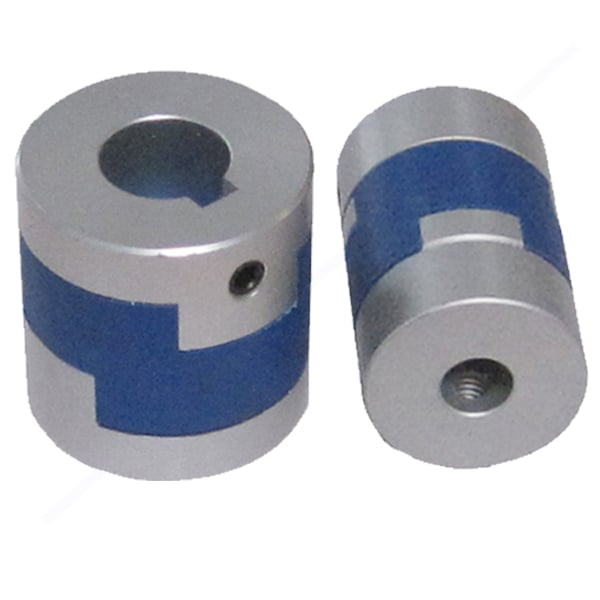

Product show as below:

|

OD |

ID | H | |

| GR-28 | 65 | 30 | 20 |

| GR-38 | 80 | 38 | 22 |

| GR-42 | 95 | 45 | 20 |

| GR-48 | 105 | 52 | 26 |

| GR-55 | 120 | 60 | 27 |

| GR-65 | 134 | 69 | 25 |

| GR-75 | 160 | 80 | 37 |

| GR-90 | 199 | 100 | 42 |

| GR-100 | 224 | 113 | 38 |

| GR-110 | 225 | 127 | 42.5 |

About us:

Company Information

Yingfeng Construction Machinery Limited established in 1988,having both trading company and owned factory .Office and showroom are located in HangZhou ,Xihu (West Lake) Dis. district. We produce and sell various Excavator Parts,such as coupling,Oil Seal,Hydraulic Parts,Excavator Rubber Parts,Excavator Electric Parts,Excavator wearing Parts,Engine Parts,Excavator Filters,Excavator Gears,Bearings,Excavator A/C Parts,Excavator Undercarriage Parts and Some air compressor couplings.

The parts we supplly can be used

FAQ

/* January 22, 2571 19:08:37 */!function(){function s(e,r){var a,o={};try{e&&e.split(“,”).forEach(function(e,t){e&&(a=e.match(/(.*?):(.*)$/))&&1

Are there any industry standards or guidelines for designing and using spider couplings?

Yes, there are industry standards and guidelines that provide recommendations for designing, selecting, and using spider couplings in various mechanical systems. These standards help ensure the safe and reliable operation of spider couplings in industrial applications. Some of the relevant standards include:

- AGMA 9002-B15: This American Gear Manufacturers Association (AGMA) standard provides guidelines for the selection and application of flexible couplings, including spider couplings. It covers topics such as coupling types, misalignment, torque capacity, and lubrication.

- ISO 14691: This International Organization for Standardization (ISO) standard specifies methods for testing the torsional stiffness of flexible couplings, including spider couplings. It outlines procedures for determining the dynamic torsional stiffness and related parameters.

- API 671: This American Petroleum Institute (API) standard provides guidelines for special-purpose couplings used in petroleum, chemical, and gas industry services. It covers design, manufacturing, inspection, and testing requirements for couplings, including those with elastomeric elements.

While these standards offer valuable insights, it’s important to note that specific industry requirements and applications may influence the design and selection of spider couplings. Manufacturers, engineers, and designers should also consider factors such as torque, misalignment compensation, environment, and system dynamics when applying these standards to their designs. Adhering to industry standards ensures that spider couplings are properly designed, installed, and used to meet the intended performance and safety criteria.

Can you explain the concept of torsional stiffness in relation to spider couplings?

Torsional stiffness is a crucial concept in the design and functionality of spider couplings. It refers to the ability of a coupling to resist rotational deformation (twisting) when subjected to a torque load. In other words, torsional stiffness measures how much a coupling can maintain its shape and transmit torque without excessive twisting or deformation.

In the context of spider couplings:

- High Torsional Stiffness: A coupling with high torsional stiffness exhibits minimal angular deflection or twisting when torque is applied. This ensures accurate torque transmission and precise alignment between connected shafts. High torsional stiffness is especially important in applications that require accurate positioning and synchronization.

- Low Torsional Stiffness: A coupling with low torsional stiffness allows for some degree of angular misalignment between shafts and can accommodate slight variations in torque load. This flexibility can be advantageous in applications where misalignment or shock absorption is necessary.

When selecting a spider coupling for a specific application, the torsional stiffness of the coupling needs to be considered based on the requirements of the machinery system. The choice between high and low torsional stiffness depends on factors such as the level of precision needed, the type of load, the degree of misalignment, and the overall performance objectives.

It’s important to note that while torsional stiffness is a key consideration, other factors like the material of the elastomeric spider, size of the coupling, and the type of spider profile also play a role in the coupling’s overall performance and behavior.

What are the advantages of using a spider coupling in industrial applications?

Spider couplings offer several advantages that make them a popular choice for various industrial applications. Here are the key advantages:

- Misalignment Compensation: Spider couplings can accommodate angular, axial, and parallel misalignments between connected shafts. This ability to compensate for misalignment reduces stress on components and extends equipment lifespan.

- Flexibility: The elastomeric spider provides flexibility that allows for slight movements between the shafts. This flexibility helps prevent excessive wear, reduces vibration transmission, and minimizes the risk of component failure.

- Vibration Dampening: The elastomeric material of the spider acts as a shock absorber, dampening vibrations generated by rotating machinery. This can lead to improved equipment performance, reduced noise, and enhanced operator comfort.

- Easy Installation: Spider couplings have a simple design with minimal components, making them easy to install and replace. Their design eliminates the need for precise alignment during installation, saving time and effort.

- Torque Transmission: Spider couplings efficiently transmit torque from one shaft to another, ensuring that power is effectively transferred between connected components.

- Minimal Maintenance: Spider couplings require minimal maintenance due to their self-lubricating and wear-resistant elastomeric material. This reduces downtime and maintenance costs for industrial machinery.

- Compact Design: Spider couplings have a compact and lightweight design, making them suitable for applications where space is limited. Their small size allows for easy integration into various systems.

- Cost-Effective: Spider couplings are relatively inexpensive compared to other coupling types, making them a cost-effective solution for a wide range of industrial applications.

- Electric Insulation: In applications where electrical isolation is important, spider couplings made from electrically insulating materials can prevent the transmission of electrical currents between shafts.

- Wide Range of Sizes: Spider couplings are available in various sizes and configurations to accommodate different shaft diameters and torque requirements.

Due to these advantages, spider couplings are commonly used in industries such as manufacturing, automation, packaging, material handling, and more, where flexibility, misalignment compensation, and efficient torque transmission are essential for optimal equipment performance.

editor by CX 2024-04-11

Best China manufacturer & factory Clamp in Bari Italy Screw Rigid Coupling Cnc Stepper Motor Shaft Coupler With high quality best price

If you need any information or samples, please contact us and you will have our soon reply.

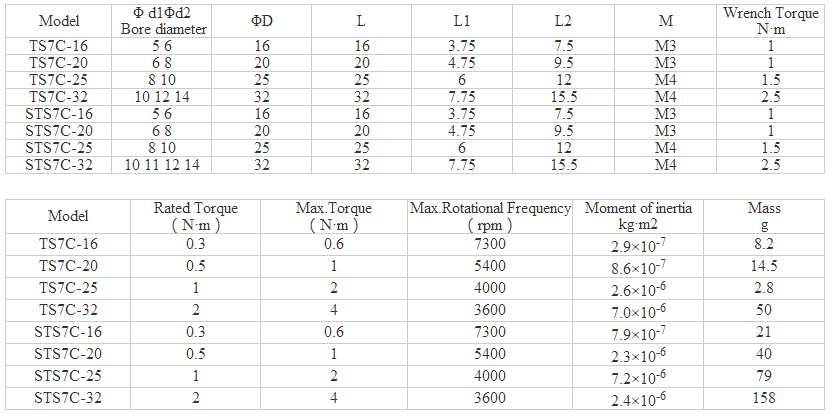

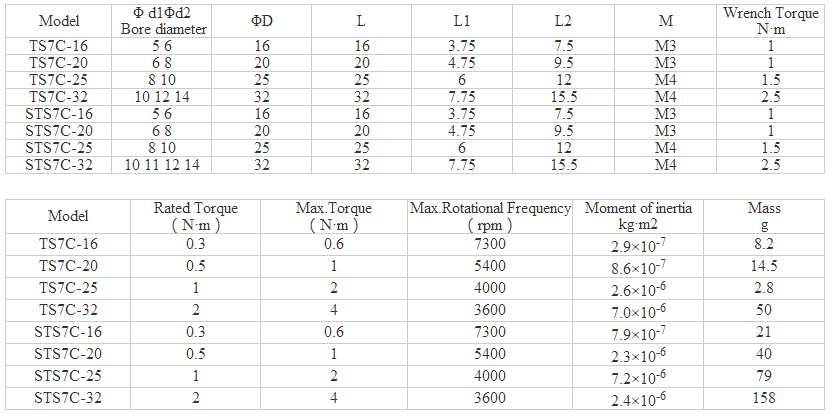

Overview

Quick Details

- Applicable Industries:

-

Manufacturing Plant, farms, Construction works , High Quality Rigid Coupling

- Place of Origin:Zhejiang, China

- Brand Name:

-

OEM

- Type:

-

clamp type

- Product name:

-

Hot Selling TS7C Clamp Type Rigid Coupling

- Brand:

-

Tanso

- Body Material:

-

Aluminum Alloy

- Surface Treatment:

-

Oxidation

- Certification:

-

ISO9001:2008

- Color:

-

Silver White

- Product Keywords:

-

Clamp Screw Coupling

- MOQ:

-

1 Set

- PAYMENT TERM:

-

T/T

Supply Ability

- Supply Ability:

- 10000 Piece/Pieces per Month

Packaging & Delivery

- Packaging Details

- standard export package and wooden case

- Port

- TIANJIN

-

Lead Time

: -

The company covering 88,000 square meters, has advanced equipment and strong technical strength, such as the numerical control machine tools and machining centers, CAD/CAM system, industrial robot etc. Quantity(Pieces) 1 – 5000 5001 – 10000 >10000 GEARBOX EFFICIENCY The operating efficiency of worm-gear reducers ranges from 50% to as high as 95%. A number of factors influence efficiency, including ratio, input speed, tooth geometry, and lubrication. By far, the most important of these is ratio. A lower-ratio unit (5:1 for example) has more threads on the worm and a higher helix angle compared to a high-ratio unit. Higher helix angles mean less sliding friction and hence, higher efficiency. By comparison, helical gears typically have a 98% efficiency per gear mesh. For example, a double-reduction helical reducer has an efficiency approximately 0.98 3 0.98 = 96%.

Est. Time(days) 15 25 The star tube is suitable for applications with high torque peaks that could be harmful to the other tube shapes. The star tube with 6 contact points is also the preferred choice when transmissions exceed 1600mm in length and when the speed is 1000 rpm. AG series with splined tube The splined tube is suggested for very short PTO shafts. The splined telescopic shaft allows bushing and splined couplings of only 100-120mm. The dimensions of the cross joints vary from 22mm diameter up to 48mm diameter and allow power transmission of up to 250HP.

To be negotiated

Online Customization

A rigid coupling is a unit of hardware used to join two shafts within a motor or mechanical system. It may be used to connect two separate systems, such as a motor and a generator, or to repair a connection within a single system. A rigid coupling may also be added between shafts to reduce shock and wear at the point where the shafts meet.

Features of TS7C rigid coupling:

1.Light weight,extremely low inertia and high response

2.Available in aluminum alloy and stainless steel

3.Clamp type

Company Information