FAQCommon Problem

Email: [email protected]

FAQ

What is a gear?What is the role of gears?Gear manufacturers announced for you

what isgear?

The toothed wheel-shaped parts are one of the most commonly used and important parts on the machines of gear manufacturers.Usually they are engaged in pairs, one of which rotates and the other is driven.Used to change the transmission direction, rotation direction, rotation speed, torque, etc.Also called cone.It is also used as a metaphor for the indispensable part of the whole business.

What is the role of gears?

Due to high transmission efficiency and transmission ratioAccurate and functionalWith the advantages of large rate range, gear mechanisms are widely used in industrial products, and their design and manufacturing level directly affects industrial production.The quality of the product.The gear teeth interlocking with each other will drive the other gear to rotate to transmit power.Divide the two gearsOpen, you can also use chains, crawlers, leather belts to drive the gears on both sides to transmit power.

For example, in a bicycle, it is the power gear from the pedal to the rear wheel.Similarly, in a car, gears transfer power from the crankshaft (the rotating shaft of power from the engine) to the drive shaft running under the car, which ultimately powers the wheels.We can connect any number of gears together, and they can have different shapes and sizes.Whenever we transfer electricity from one gear to another, we can do one of two things: Gearbox bicycle gears increase speed: if you connect two gears together, the first gear is more than the second gear, The second gear must turn faster to keep up.Therefore, this arrangement means that the second wheel rotates faster than the first wheel, but with less force.

The names and basic parameters of each part of the gear :

End surface-a plane perpendicular to the axis of the gear

Normal surface-the plane perpendicular to the tooth line of the gear

Tooth line──the line of intersection between the tooth surface and the indexing cylindrical surface

Base circle ── a circle on which the involute line of occurrence is purely rolling

Tooth width b ──The size of the gear teeth along the axial direction

Reference rack ──The rack cut out according to its standard gear specifications is called the reference rack

Pitch Circle ──The occlusal contact point of the two gears is called the pitch circle.

Pitch Diameter ──Pitch Diameter

Index circle ─ ─ Between the addendum circle and the root circle, a circle with a diameter of d is specified as the reference for calculating the size of each part of the gear. This circle is called the index circle.The size of the index circle is determined by the tooth pitch and the number of teeth.

Divided circumference dπ=mz, d= pz/π

1. Index circle: the circle on the gear as the reference of the gear size, denoted by d

2. Tooth pitch: the length of the indexing arc between two adjacent teeth on the same side profile, denoted by p

3. Modulus: the ratio of tooth pitch P to π, expressed in m

4. Pressure angle: the pressure angle a at the intersection of the involute tooth profile and the index circle, the national standard pressure angle is 20 degrees

5. Addendum height: the radial height from the index circle to the addendum circle, expressed in ha

6. Head clearance: After the two gears are assembled, the gap distance left by the two meshing teeth in the radial direction, denoted by C

7. Tooth root height: the radial height from the index circle to the tooth root circle, expressed in hf

8. Total tooth height: the radial height from the tooth tip circle to the tooth root circle, represented by h

★The correct meshing condition of spur gear: equal modulus and equal pressure angle

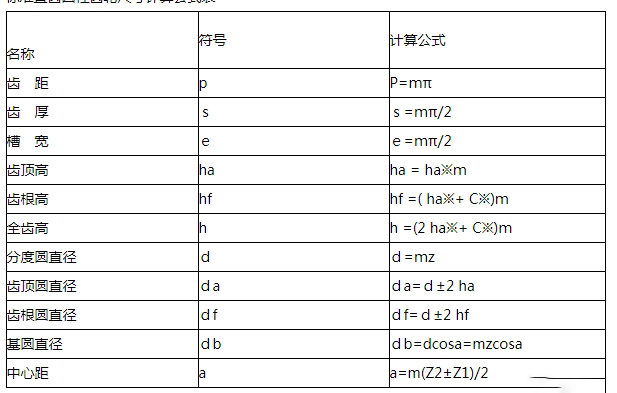

Standard spur gear size calculation formula table

- What is a coupling?Let you understand the principle of coupling in one minute 2019-11-13

- What is the way to disassemble and install the coupling? 2019-10-20

- Type and photo of coupling? 2019-10-18

- How to make the coupling give full play to a stronger practical effect? 2019-10-05

- What are the raw materials for the transmission gear 2019-10-02