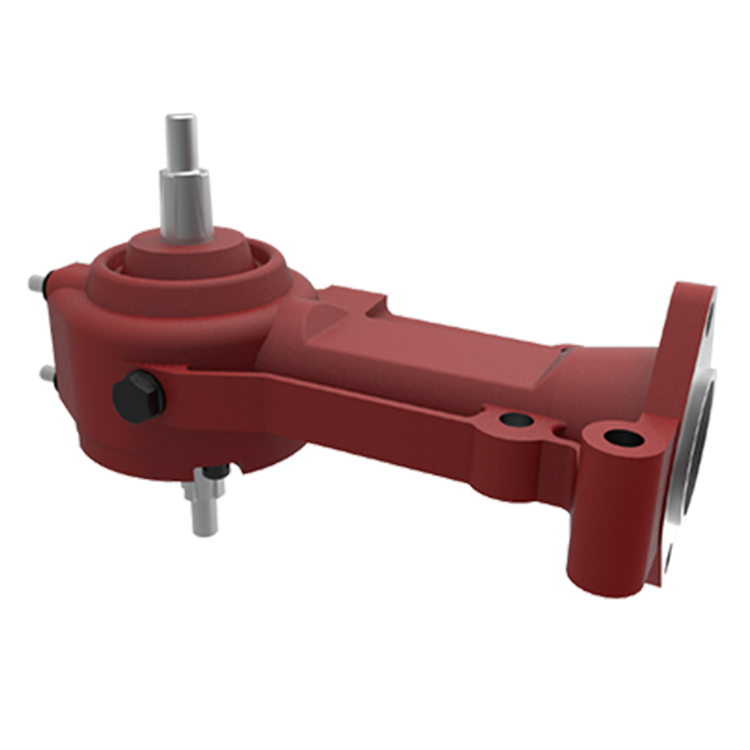

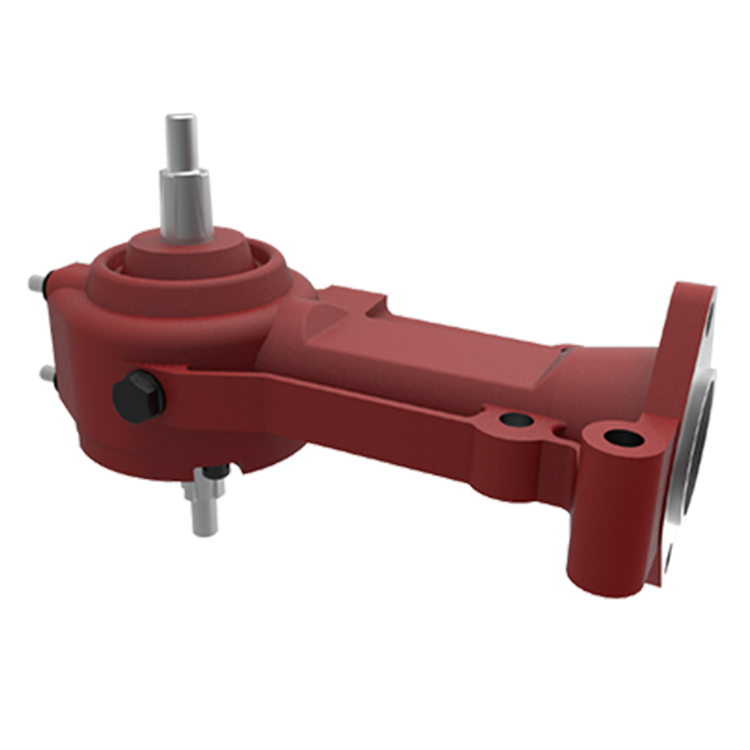

Product Description

New design Factory High Torque Customized Flexible Spider Jaw Shaft Coupling with low price

Description:

One of the most widely applied types of flexible couplings is an elastomeric design known as the jaw coupling. This design is characterised by 2 hubs, each having 2 or more thick, stubby protrusions around their perimeters, called jaws, pointing toward the opposing hub. These jaws mesh loosely when the 2 hubs are brought together. Filling the gaps between the jaws are blocks of elastomeric material, usually molded into a single asterisk-shaped element called a “spider”.

Just as coupling designs vary to satisfy different application criteria, so do the spiders in jaw-type couplings. The spider is the key determinant of the torque rating of each jaw coupling. It also can make a significant difference in the coupling’s response to vibration, temperature, chemicals, misalignment, high RPM, space limitations and ease of installation or removal.

Features:

1,Elastic plum-shaped flexible coupling

2,During transmission, it can realize zero backlash torque transmission torque under low torque state

3,The elastic spacer is made of polyurethane, and the torque exceeds the traditional claw coupling by more than 2 times

4,Plum CHINAMFG elastomer can resist oil and electrical insulation, operating temperature: -20ºC~80ºC

5,Excellent elastic effect to absorb vibration, eccentricity and deflection

6,If there are multiple deviations, the allowable value of a single deviation will be reduced

Product paramters:

Packing & shipping:

1 Prevent from damage.

2. As customers’ requirements, in perfect condition.

3. Delivery : As per contract delivery on time

4. Shipping : As per client request. We can accept CIF, Door to Door etc. or client authorized agent we supply all the necessary assistant.

Application:

Building Material Shops, Manufacturing Plant, Machinery Repair Shops, Retail, Printing Shops, Construction works , Energy & Mining.

About us:

HangZhou CHINAMFG machinery technology Co., Ltd is an industry transmission solutions manufacuturer and service provider.

We offer 1 stop solution for power transmission products for different factories, such as chemicals, energy, material handling, environmental, extraction, pulp and paper, steel and metal, food and beverage, and construction industries.

We supply: Customised gears, Small gearmotors, Industrial gearboxes, Motors, Brand product sourcing.

Our industrial Gear, Gearbox, gearmotor and motor are sold to more than 30 countries. High quality, good price, in time response and sincere service are our value and promises. We aim at making happy cooperation with our customers, bring them reliable and comfortable service.

/* January 22, 2571 19:08:37 */!function(){function s(e,r){var a,o={};try{e&&e.split(“,”).forEach(function(e,t){e&&(a=e.match(/(.*?):(.*)$/))&&1

What materials are typically used in manufacturing spider couplings and why?

Spider couplings are constructed using a combination of materials to achieve durability, flexibility, and efficient torque transmission. The choice of materials depends on factors such as application requirements, environmental conditions, and the desired balance between strength and flexibility. Common materials used in manufacturing spider couplings include:

- Aluminum: Aluminum is lightweight and corrosion-resistant, making it suitable for applications where weight reduction is important. It offers good mechanical properties and can be used in various industries.

- Steel: Steel provides excellent strength and durability. It’s often used in heavy-duty applications where high torque transmission is required. Surface treatments can enhance corrosion resistance.

- Stainless Steel: Stainless steel offers corrosion resistance in aggressive environments. It’s commonly used in industries such as food processing, pharmaceuticals, and chemical processing.

- Cast Iron: Cast iron is known for its high compressive strength and wear resistance. It’s suitable for applications requiring robust construction and can handle high torque loads.

- Plastic/Polymer: Certain polymers and plastics, such as polyurethane or nylon, are used for the elastomeric spider element. These materials provide flexibility, vibration dampening, and misalignment compensation.

The choice of materials depends on the specific requirements of the application. For example, aluminum or stainless steel may be chosen for industries requiring corrosion resistance, while steel or cast iron may be selected for heavy-duty applications. The elastomeric spider is typically made from a durable polymer to ensure flexibility and effective torque transmission while accommodating misalignment. Overall, selecting the right materials ensures that spider couplings can withstand the demands of the intended application and provide reliable performance over their lifespan.

What are the best practices for ensuring proper lubrication of spider couplings?

Proper lubrication is essential for maintaining the performance and lifespan of spider couplings. Here are some best practices to ensure proper lubrication:

- Use the Right Lubricant: Select a lubricant that is recommended by the coupling manufacturer. The lubricant should be compatible with the elastomeric spider material and the operating conditions of the machinery.

- Follow Manufacturer’s Guidelines: Adhere to the lubrication schedule and guidelines provided by the manufacturer. They will specify the appropriate lubrication intervals and the quantity of lubricant to be applied.

- Clean the Components: Before applying lubricant, make sure the coupling components are clean and free of dirt, debris, and old lubricant residues. Cleaning the components prevents contamination of the new lubricant.

- Apply Lubricant Evenly: Apply the lubricant evenly on all contact surfaces of the elastomeric spider and the coupling hub. Avoid over-lubrication, which can lead to excess buildup and potential slippage.

- Use Lubrication Tools: Some couplings may have lubrication ports or fittings that facilitate the application of lubricant. If such features are present, use the appropriate lubrication tools to ensure thorough coverage.

- Operate Coupling After Lubrication: After applying lubricant, operate the coupling for a short period to ensure that the lubricant is evenly distributed across the contact surfaces. This helps in preventing dry spots and optimizing lubrication effectiveness.

- Monitor Lubricant Condition: Regularly inspect the condition of the lubricant during routine maintenance checks. If you notice signs of contamination, degradation, or insufficient lubrication, take corrective actions promptly.

- Consider Operating Conditions: Environmental factors such as temperature, humidity, and exposure to chemicals can affect the performance of lubricants. Choose a lubricant that can withstand the specific operating conditions of the machinery.

- Document Lubrication Activities: Keep a record of lubrication activities, including the type of lubricant used, lubrication intervals, and the results of lubrication checks. This documentation helps track the history of lubrication and informs future maintenance decisions.

By following these best practices for lubrication, you can ensure that the elastomeric spider remains properly lubricated, reducing friction, wear, and the potential for premature coupling failure.

How do you properly install and maintain a spider coupling in machinery?

Installation:

Proper installation of a spider coupling is essential to ensure its optimal performance and longevity. Here are the steps for installing a spider coupling:

- Ensure Safety: Before starting any installation, make sure the machinery is properly shut down and all energy sources are disconnected.

- Inspect Components: Check the hubs, elastomeric spider, and shafts for any damage or debris. Ensure that the components match the correct specifications.

- Align Shafts: Align the shafts to minimize initial misalignment before inserting the elastomeric spider.

- Insert Spider: Place the elastomeric spider into one of the hubs, ensuring that the lobes or fins are correctly aligned with the grooves in the hub.

- Align Second Hub: Carefully align the second hub with the first one, making sure the spider lobes fit into the grooves of both hubs.

- Press Hubs Together: Gently press the hubs together until they meet. Avoid using excessive force, as this could damage the elastomeric spider.

- Check Alignment: After installation, check the alignment of the shafts and the coupling. Misalignment should not exceed the manufacturer’s recommended limits.

- Tighten Fasteners: Tighten the fasteners on the hubs according to the manufacturer’s torque specifications. Use a torque wrench to ensure proper tightening.

- Verify Clearance: Check for proper clearance between the coupling and surrounding components to prevent interference during operation.

- Run System: Start the machinery and monitor the coupling for any unusual vibrations or noise. Make any necessary adjustments if issues are detected.

Maintenance:

Maintaining a spider coupling is important to ensure its continued performance and prevent premature failure. Here are some maintenance tips:

- Regular Inspection: Periodically inspect the spider coupling for signs of wear, damage, or deterioration. Look for cracks, tears, or other abnormalities in the elastomeric spider.

- Clean Environment: Keep the coupling and surrounding area clean from dirt, debris, and contaminants that could impact its performance.

- Lubrication: Spider couplings are self-lubricating due to the elastomeric material. Avoid using additional lubricants, as they can deteriorate the elastomeric properties.

- Temperature Consideration: Be aware of the temperature range specified by the manufacturer for the elastomeric material. Extreme temperatures can affect the performance and lifespan of the coupling.

- Replace Worn Parts: If the elastomeric spider shows signs of wear, replace it with a new one from the manufacturer. Do not continue using a worn or damaged spider.

- Monitor Vibrations: Regularly monitor the machinery for unusual vibrations or noise, as these can indicate issues with the coupling. Address any problems promptly.

- Follow Manufacturer Guidelines: Adhere to the manufacturer’s recommended maintenance schedule and guidelines for the specific spider coupling model.

Proper installation and regular maintenance contribute to the reliable and efficient operation of a spider coupling in machinery.

editor by CX 2024-04-22

China Best Sales Best Price Good Quality L035 L050 L070 L090 L095 L110 Lovejoy Spider Coupling Flexible Shaft Rubber Coupling for Motor Coupling

Product Description

| Product Name | Coupling | Place of origin | China |

| Brand | Mighty | Material | Steel /Cast Iron |

1. Engineering: machine tools, foundry equipments, conveyors, compressors, painting systems, etc.

2. Pharmaceuticals& Food Processing: pulp mill blowers, conveyor in warehouse, agitators, grain, boiler, bakery machine, labeling machine, robots, etc.

3. Agriculture Industries: cultivator, rice winnower tractor, harvester, rice planter, farm equipment, etc.

4. Texitile Mills: looms, spinning, wrappers, high-speed auto looms, processing machine, twister, carding machine, ruler calendar machine, high speed winder, etc.

5. Printing Machinery: newspaper press, rotary machine, screen printer machine, linotype machine offset printer, etc.

6. Paper Industries: chipper roll grinder, cut off saw, edgers, flotation cell and chips saws, etc.

7. Building Construction Machinery: buffers, elevator floor polisher mixing machine, vibrator, hoists, crusher, etc.

8. Office Equipments: typewriter, plotters, camera, money drive, money sorting machine, data storage equipment, etc.

9. Glass and Plastic Industries: conveyor, carton sealers, grinders, creeper paper manufacturing machine, lintec backing, etc.

10. Home Appliances: vacuum cleaner, laundry machine, icecream machine, sewing machine, kitchen equipments, etc.

/* January 22, 2571 19:08:37 */!function(){function s(e,r){var a,o={};try{e&&e.split(“,”).forEach(function(e,t){e&&(a=e.match(/(.*?):(.*)$/))&&1

What materials are typically used in manufacturing spider couplings and why?

Spider couplings are constructed using a combination of materials to achieve durability, flexibility, and efficient torque transmission. The choice of materials depends on factors such as application requirements, environmental conditions, and the desired balance between strength and flexibility. Common materials used in manufacturing spider couplings include:

- Aluminum: Aluminum is lightweight and corrosion-resistant, making it suitable for applications where weight reduction is important. It offers good mechanical properties and can be used in various industries.

- Steel: Steel provides excellent strength and durability. It’s often used in heavy-duty applications where high torque transmission is required. Surface treatments can enhance corrosion resistance.

- Stainless Steel: Stainless steel offers corrosion resistance in aggressive environments. It’s commonly used in industries such as food processing, pharmaceuticals, and chemical processing.

- Cast Iron: Cast iron is known for its high compressive strength and wear resistance. It’s suitable for applications requiring robust construction and can handle high torque loads.

- Plastic/Polymer: Certain polymers and plastics, such as polyurethane or nylon, are used for the elastomeric spider element. These materials provide flexibility, vibration dampening, and misalignment compensation.

The choice of materials depends on the specific requirements of the application. For example, aluminum or stainless steel may be chosen for industries requiring corrosion resistance, while steel or cast iron may be selected for heavy-duty applications. The elastomeric spider is typically made from a durable polymer to ensure flexibility and effective torque transmission while accommodating misalignment. Overall, selecting the right materials ensures that spider couplings can withstand the demands of the intended application and provide reliable performance over their lifespan.

What are the best practices for ensuring proper lubrication of spider couplings?

Proper lubrication is essential for maintaining the performance and lifespan of spider couplings. Here are some best practices to ensure proper lubrication:

- Use the Right Lubricant: Select a lubricant that is recommended by the coupling manufacturer. The lubricant should be compatible with the elastomeric spider material and the operating conditions of the machinery.

- Follow Manufacturer’s Guidelines: Adhere to the lubrication schedule and guidelines provided by the manufacturer. They will specify the appropriate lubrication intervals and the quantity of lubricant to be applied.

- Clean the Components: Before applying lubricant, make sure the coupling components are clean and free of dirt, debris, and old lubricant residues. Cleaning the components prevents contamination of the new lubricant.

- Apply Lubricant Evenly: Apply the lubricant evenly on all contact surfaces of the elastomeric spider and the coupling hub. Avoid over-lubrication, which can lead to excess buildup and potential slippage.

- Use Lubrication Tools: Some couplings may have lubrication ports or fittings that facilitate the application of lubricant. If such features are present, use the appropriate lubrication tools to ensure thorough coverage.

- Operate Coupling After Lubrication: After applying lubricant, operate the coupling for a short period to ensure that the lubricant is evenly distributed across the contact surfaces. This helps in preventing dry spots and optimizing lubrication effectiveness.

- Monitor Lubricant Condition: Regularly inspect the condition of the lubricant during routine maintenance checks. If you notice signs of contamination, degradation, or insufficient lubrication, take corrective actions promptly.

- Consider Operating Conditions: Environmental factors such as temperature, humidity, and exposure to chemicals can affect the performance of lubricants. Choose a lubricant that can withstand the specific operating conditions of the machinery.

- Document Lubrication Activities: Keep a record of lubrication activities, including the type of lubricant used, lubrication intervals, and the results of lubrication checks. This documentation helps track the history of lubrication and informs future maintenance decisions.

By following these best practices for lubrication, you can ensure that the elastomeric spider remains properly lubricated, reducing friction, wear, and the potential for premature coupling failure.

What is a spider coupling and how is it used in mechanical systems?

A spider coupling, also known as a jaw coupling or elastomeric coupling, is a type of flexible coupling used to connect two shafts while accommodating misalignment and transmitting torque between them. It consists of three main components: two hubs and an elastomeric spider or insert that fits between them.

The elastomeric spider is typically made of a flexible and durable material, such as rubber or polyurethane, with a series of lobes or fins that fit into matching grooves on the inner surfaces of the hubs. These lobes allow the spider to flex and absorb misalignments between the connected shafts while transmitting torque.

The spider coupling is used in mechanical systems to:

- Transmit Torque: The primary function of a spider coupling is to transmit torque from one shaft to another. As the shafts rotate, the elastomeric spider deforms slightly, allowing the hubs to move relative to each other while maintaining torque transmission.

- Accommodate Misalignment: Spider couplings can accommodate different types of misalignment, including angular, axial, and parallel misalignments, without causing excessive stress on the connected components. This flexibility helps prevent premature wear and failure.

- Dampen Vibrations: The elastomeric material of the spider acts as a shock absorber, dampening vibrations and reducing the transmission of vibrations between the connected shafts. This can improve overall system performance and reduce wear on components.

- Isolate Shock Loads: In applications with sudden changes in torque or shock loads, the spider coupling can absorb and dampen these shocks, protecting the connected components from damage.

- Reduce Maintenance: Spider couplings require minimal maintenance due to their simple design and absence of lubrication points. This can lead to reduced downtime and maintenance costs in industrial machinery.

- Provide Electric Insulation: Spider couplings can provide electrical isolation between the connected shafts, making them suitable for applications where electrical grounding needs to be minimized.

Spider couplings are commonly used in various machinery and equipment, such as pumps, compressors, conveyors, fans, and industrial machinery. They are particularly well-suited for applications that require flexibility, misalignment compensation, vibration reduction, and ease of maintenance.

editor by CX 2024-03-28

China manufacturer & factory supplier for Agricultural in Surabaya Indonesia flexible pto spline shaft front or rear drive shaft With high quality best price & service

corrosion- and use-resistant coiled tubing injector roller chain assemblies for the oil and fuel industries. Accessible in solitary and double pitch travel chain varieties with various dimensions and electrical power score. Attributes contain zinc-nickel and non-hexavalent chromate protective exterior coating, electrochemically bonded, and interference in shape protect plates.We are searching forward to developing effective business interactions with new customers about the world in the potential.

Overview

QuiOur goods are marketing properly in Chinese markets and some products sold in global markets are well acquired by Chinese and foreign clientele at residence and abroad.ck Specifics

- Condition:

-

New

- Warranty:

-

1.5 years

- Relevant Industries:

-

Production Plant, Farms, Agricultural Tractors Pto Travel Shaft Common Cr

- Soon after Warranty Service:

-

On-line help

- Regional Service Location:

-

None, Italy

- Showroom Area:

-

Malaysia

- Online video outgoing-inspection:

-

Presented

- Equipment Take a look at Report:

-

Provided

- Advertising and marketing Variety:

-

New Merchandise 2020

- Kind:

-

Shafts

- Use:

-

Cultivators

- Location of Origin:Zhejiang, China

- Model Name:

-

OEM

Worm-gear speed reducers have offered a rugged, adaptable, and expense-successful method of energy transmission for nearly a century. But their acceptance in modern years has been relatively diminished by inherent inefficiency and a status for sooner or later developing oil leaks. Extensive research into these two related troubles has pinpointed numerous contributing factors:

- certification:

-

CE

- Materials:

-

Steel

- Processing of yoke:

-

Forging

- Design:

-

Custom-made

- Certification:

-

CE Certification

Provide Capacity

- Provide Ability:

- 20000 Piece/Parts per Month

Packaging & Delivery

- Packaging Specifics

- Packing information:Iron pallet&picket carton&common export packaging

- Port

- NINGBO OR SHANGHAI

-

Guide Time

: -

Quantity(Pieces) 1 – 9999 If you’re searching for a 540 PTO shaft, 540 to a thousand PTO adapter, 540 PTO hydraulic pump, or a 540 PTO gearbox, appear no more. It is essential to substitute PTO parts that are worn or cracking before you have a significant breakdown that could be pricey and even harmful. We have PTO travel shafts as effectively as essential defend elements for your security. Our Eurocardan areas contain a assortment of sorts of clutches to boost the procedure of your electrical power get-off program. PTO shafts and accessories are an critical portion of the far more than 26,000 objects we have for farm, store, property and backyard.

>9999 Est. Time(times) 12 To be negotiated

On-line Customization

Relevant item

Business Profile

Packing & Shipping and delivery

Best China manufacturer & factory Wholesale Cheap Flexible Power transmission China Pto Shaft With high quality best price

We are aiming to meet the demands of the clients around the world.. a specialized supplier of a full range of chains, sprockets, gears, gear racks, V-belts, couplings and reducers, pto shaft, agricultural gearboxes….

Overview

Quick Details

- Warranty:

-

1.5 years

- Applicable Industries:

-

Manufacturing Plant

- After Warranty Service:

-

Online support

- Local Service Location:

-

none, Italy

- Showroom Location:

-

ITALY

- Type:

-

Shafts

- Place of Origin:Zhejiang, China

- Brand Name:

-

OEM

- certificate:

-

CE

- Material:

-

Metal

- Color:

-

Yellow&Black

- Processing of yoke:

-

Forging

- Processing of tube:

-

Cold drawn

- Design:

-

Customized

- Certificate:

-

CE Certificate

Supply Ability

- Supply Ability:

- 20000 Piece/Pieces per Month

Worm gears are typically manufactured by hobbing with a hob or cutting tool very similar to the worm that the gear mates with. The worm may be turned, hobbed, milled, or ground.

Packaging & Delivery

- Packaging Details

- Packing details:Iron pallet&wooden carton&standard export packaging

- Port

- ningbo or shanghai

Online Customization

PTO Shaft A PTO Adapter will be useful when operating Victory’s EMSD and EMHD Embankment Flail mowers. The absence of a PTO Adapter could cause the PTO shaft to conflict with the arm weldment, which connects to the CAT I/II 3 point hitch.

Product Information

Product Information

PTO Shaft

The power take-off (PTO) is a sophisticated mechanism, allowing implements to draw energy from the engine and transmit it to another application. It works as a mechanical gearbox which can be mounted on the vehicle’s transmission.

The power take-off shaft (PTO shaft) is a critical component, designed and manufactured for continuous heavy-duty use. A good PTO shaft should be strong enough to bear the torsion and shear stress and minimize vibration.

Setforge, the forging subsidiary of Ever-Power Group, manufactures cold extruded PTO shafts for all types of agriculture vehicles. Our PTO shafts offer great dependability and durability during daily use.

EP Group has been internationally recognized as a reliable global supplier. Our state-of-the-art manufacturing process and experienced engineers ensure the top-quality of all Farinia components.

| After Warranty Service | Video technical support |

| Applicable Industries | Manufacturing Plant |

| Local Service Location | Italy |

| Showroom Location | Italy |

| Warranty | 1.5 years |

| Type | Shafts |

| Place of Origin | China |

| China | Zhejiang |

| Brand Name | EPG |

| certificate | CE |

| Material | Metal |

| Color | Yellow&Black |

| Processing of yoke | Forging |

| Processing of tube | Cold drawn |

| Design | Customized |

| Certificate | CE Certificate |

Product Display

Product Display

6″ Rock Auger

Tie Rod Cylinder H …

Agricultural Gearb …

CompanyInfo

Company Profile

Ever-Power Group

EPG have high-tech machinery and test equipment. We can produceThe company was certified by ISO9001:2008 Quality Management System. world class high precision products.

Certifications

Certifications

Shipment & Payment

Our Advantages

A: Your inquiry related to our products or prices will be replied in 24 hours.

B: Protection of your sales area, ideas of design and all your private information.

C: Best quality and competitive price.

……

faq

FAQ

1) How can I place order?

A: You can contact us by email about your order details, or place order on line.

2) How can I pay you?

A: After you confirm our PI, we will request you to pay. T/T (HSBC bank) and Paypal, Western Union are the most usual ways we are using.

……

Zl China pto shaft stock Lz Series High Quality Flexible Pin Gear Coupling with ce certificate top quality low price

We – EPG Group the biggest agricultural gearbox and pto factory in China with five diverse branches. For a lot more information: Cellular/whatsapp/telegram/Kakao us at: 0086-13083988828

Established in the year 1 0571 at EPG, we “EPG” are a Sole Proprietorship based company, engaged as the foremost Manufacturer of Mist Blower, Agricultural Gearbox and numerous much more. Our items are substantial in desire due to their premium good quality and affordable charges. Furthermore, we ensure to well timed supply these products to our clientele, by means of this we have obtained a massive customers base in the marketplace.

LZ Elastic Pin Equipment Coupling(GB/T5015-2003)

LZ Large Top quality Elastic Pin Equipment Coupling uses nylon rod to turn the column pin into the reverse hole between the two 50 percent coupling and the outer ring inner surface, and transfers the torque by means of the column pin to recognize the relationship in between two half couplings. It has specified shaft offset compensation ability and shock absorption efficiency. LZ Large Quality Elastic Pin Gear Coupling is symmetrical and interchangeable, extended lifestyle, allowing large axial movement, and has the performance of cushioning, damping, use resistance and so on. The shaft holes of the two axle head of the pin sort coupling of the LZ elastic column are all straight holes.

♦LZ Elastic Pin Gear Coupling Standard Parameter And Main Diamention(GB/T5015-2003)

| Model | Nominal Torque Tn Kn·m |

Pace (n) r/min |

Shaft gap diameter d |

Shaft gap duration | D | D1 | B | S | Rotary inertia kg·m2 |

Mass kg |

| Y variety J1sort | ||||||||||

| L | ||||||||||

| LZ1 | .112 | 5000 | 12-24 | 27-52 | 76 | forty | 42 | two.5 | .001 | one.67 |

| LZ2 | .twenty five | 5000 | sixteen-32 | forty four-82 | 90 | fifty | 50 | 2.five | .003 | 3.00 |

| LZ3 | .63 | 4500 | twenty five-42 | 44-112 | 118 | sixty five | 70 | three. | .twelve | 7.31 |

| LZ4 | one.8 | 4200 | forty-60 | eighty four-142 | 158 | 90 | 90 | four | .045 | 16.twenty |

| LZ5 | four.5 | 4000 | fifty-80 | eighty four-172 | 192 | one hundred twenty | 90 | 4 | .108 | 27.02 |

| LZ6 | eight | 3300 | sixty-ninety five | 107-172 | 230 | a hundred thirty | 112 | five | .242 | 40.fifty nine |

| LZ7 | eleven.two | 2900 | 70-one hundred ten | 107-212 | 260 | one hundred sixty | 112 | 5 | .443 | fifty nine.60 |

| LZ8 | 18 | 2500 | 80-a hundred thirty | 132-252 | three hundred | one hundred ninety | 128 | 6 | . 571 | ninety four.67 |

| LZ9 | 25 | 2300 | ninety-a hundred and fifty | 132-252 | 571 | 220 | a hundred and fifty | 7 | one.733 | thirteen.8 |

| LZ10 | 31.5 | 2100 | a hundred-one hundred seventy | 167-302 | 571 | 245 | 152 | eight | two.422 | 169.three |

| LZ11 | forty | 2000 | 110-one hundred eighty | 167-302 | 380 | 260 | 172 | 8 | three.369 | 203.1 |

| LZ12 | 63 | 1700 | a hundred thirty-200 | 202- 571 | 445 | 290 | 182 | 8 | 6.524 | 296.six |

| LZ13 | 100 | 1500 | one hundred fifty-240 | 202-410 | 571 | 345 | 218 | eight | 14.19 | 571 .two |

| LZ14 | 125 | 1400 | one hundred seventy-260 | 242-410 | 560 | 390 | 218 | eight | 21.sixty seven | 621.seven |

| LZ15 | a hundred and sixty | 1300 | a hundred ninety-three hundred | 282- 571 | 590 | 420 | 240 | 10 | 29.52 | 571 .5 |

| LZ16 | 250 | a thousand | 220-340 | 282- 571 | 695 | 490 | 265 | ten | 62.forty seven | 1144 |

| LZ17 | 571 | 950 | 240-380 | 330- 571 | 571 | 571 | 285 | 10 | 106. | one 571 |

| LZ18 | 450 | 850 | 250-420 | 330-650 | 860 | 605 | three hundred | 13 | a hundred seventy five.4 | 2062 |

| LZ19 | 630 | 571 | 280-450 | 380-650 | 571 | 695 | 322 | fourteen | 323.two | 3068 |

| LZ20 | 1120 | 650 | 320-five hundred | 380-650 | 1160 | 800 | 571 | 15 | 669.4 | 571 5 |

| LZ21 | 1800 | 530 | 380-630 | 450-800 | 1440 | 1571 | 360 | 18 | 1880 | 8699 |

| LZ22 | 2240 | five hundred | 420- 571 | 540-800 | 1520 | 1100 | 405 | 19 | two 571 | 9 571 |

| LZ23 | 2800 | 460 | 480-850 | 540-880 | 1640 | 1240 | 440 | twenty | 571 two | 12095 |

♦Product Demonstrate

♦Other Products List

| Transmission Machinery Components Title |

Design |

| Universal Coupling | WS,WSD,WSP |

| Cardan Shaft | SWC,SWP,SWZ |

| Tooth Coupling | CL,CLZ,GCLD,GIICL, GICL,NGCL,GGCL,GCLK |

| Disc Coupling | JMI,JMIJ,JMII,JMIIJ |

| Higher Versatile Coupling | LM |

| Chain Coupling | GL |

| Jaw Coupling | LT |

| Grid Coupling | JS |

♦Our Business

Our firm provides various varieties of products. Large good quality and sensible value. We adhere to the theory of “quality initial, provider very first, ongoing enhancement and innovation to satisfy the clients” for the administration and “zero defect, zero issues” as the high quality goal. To EPT our services, we offer the merchandise with very good good quality at the realistic price tag.

Welcome to customise merchandise from our manufacturing facility and you should supply your design drawings or speak to us if you need other requirements.

♦Our Solutions

one.Layout Providers

Our layout team has expertise in cardan shaft relating to product design and development. If you have any wants for your new item or would like to make additional advancements, we are here to offer our support.

two.Item Providers

uncooked materia EPT → Cutting → Forging →Rough machining →Shot blasting →Heat remedy →Testing →Fashioning →Cleaning→ Assembly→Packing→Shipping

3.Samples Process

We could create the sample according to your necessity and amend the sample continually to meet your need to have.

4.Study & Advancement

We usually study the new demands of the industry and develop the new design when there is new automobiles in the industry.

5.Good quality Handle

Every single step should be EPT check by Specialist Personnel according to the regular of ISO9001 and TS16949.

♦FAQ

Q 1: Are you investing business or maker?

A: We are a specialist producer specializing in manufacturing

different collection of couplings.

Q 2:Can you do OEM?

Yes, we can. We can do OEM & ODM for all the customers with personalized artworks of PDF or AI structure.

Q 3:How lengthy is your supply time?

Typically it is 20-30 times if the items are not in stock. It is according to quantity.

Q 4: Do you supply samples ? Is it free or extra ?

Of course, we could offer you the sample but not for cost-free.In fact we have a really very good value basic principle, when you make the bulk get then cost of sample will be deducted.

Q 5: How lengthy is your guarantee?

A: Our Guarantee is 12 month underneath normal circumstance.

Q 6: What is the MOQ?

A:Usually our MOQ is 1pcs.

Q 7: Do you have inspection procedures for coupling ?

A:one hundred% self-inspection just before packing.

Q 8: Can I have a check out to your manufacturing unit just before the get?

A: Certain,welcome to go to our manufacturing unit.

Q 9: What is actually your payment?

A:one) T/T. two) L/C

♦Contact Us

Net:

Insert: No.1 EPT Road,Chengnan park,HangZhou Town,ZheJiang Province,China