Product Description

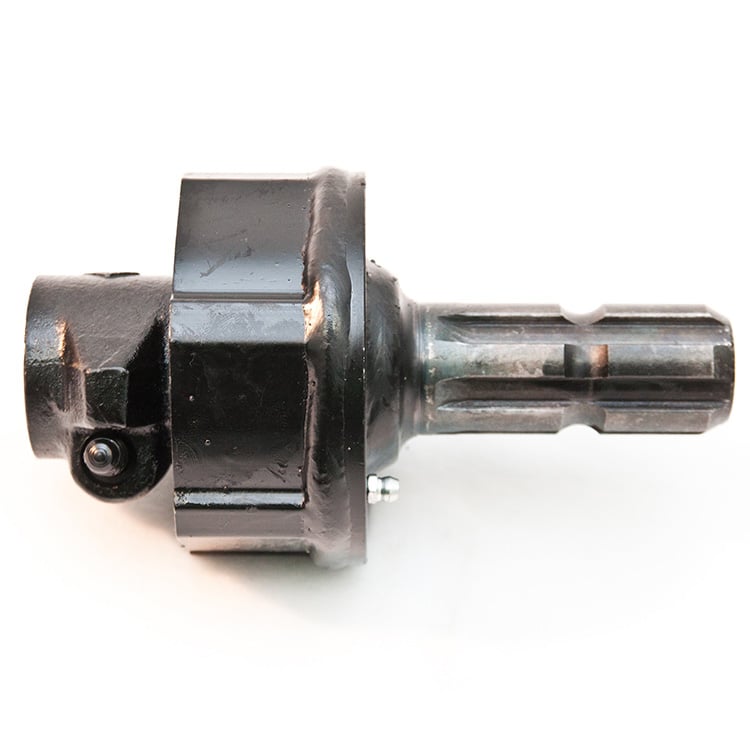

New design Factory High Torque Customized Flexible Spider Jaw Shaft Coupling with low price

Description:

One of the most widely applied types of flexible couplings is an elastomeric design known as the jaw coupling. This design is characterised by 2 hubs, each having 2 or more thick, stubby protrusions around their perimeters, called jaws, pointing toward the opposing hub. These jaws mesh loosely when the 2 hubs are brought together. Filling the gaps between the jaws are blocks of elastomeric material, usually molded into a single asterisk-shaped element called a “spider”.

Just as coupling designs vary to satisfy different application criteria, so do the spiders in jaw-type couplings. The spider is the key determinant of the torque rating of each jaw coupling. It also can make a significant difference in the coupling’s response to vibration, temperature, chemicals, misalignment, high RPM, space limitations and ease of installation or removal.

Features:

1,Elastic plum-shaped flexible coupling

2,During transmission, it can realize zero backlash torque transmission torque under low torque state

3,The elastic spacer is made of polyurethane, and the torque exceeds the traditional claw coupling by more than 2 times

4,Plum CHINAMFG elastomer can resist oil and electrical insulation, operating temperature: -20ºC~80ºC

5,Excellent elastic effect to absorb vibration, eccentricity and deflection

6,If there are multiple deviations, the allowable value of a single deviation will be reduced

Product paramters:

Packing & shipping:

1 Prevent from damage.

2. As customers’ requirements, in perfect condition.

3. Delivery : As per contract delivery on time

4. Shipping : As per client request. We can accept CIF, Door to Door etc. or client authorized agent we supply all the necessary assistant.

Application:

Building Material Shops, Manufacturing Plant, Machinery Repair Shops, Retail, Printing Shops, Construction works , Energy & Mining.

About us:

HangZhou CHINAMFG machinery technology Co., Ltd is an industry transmission solutions manufacuturer and service provider.

We offer 1 stop solution for power transmission products for different factories, such as chemicals, energy, material handling, environmental, extraction, pulp and paper, steel and metal, food and beverage, and construction industries.

We supply: Customised gears, Small gearmotors, Industrial gearboxes, Motors, Brand product sourcing.

Our industrial Gear, Gearbox, gearmotor and motor are sold to more than 30 countries. High quality, good price, in time response and sincere service are our value and promises. We aim at making happy cooperation with our customers, bring them reliable and comfortable service.

/* January 22, 2571 19:08:37 */!function(){function s(e,r){var a,o={};try{e&&e.split(“,”).forEach(function(e,t){e&&(a=e.match(/(.*?):(.*)$/))&&1

What materials are typically used in manufacturing spider couplings and why?

Spider couplings are constructed using a combination of materials to achieve durability, flexibility, and efficient torque transmission. The choice of materials depends on factors such as application requirements, environmental conditions, and the desired balance between strength and flexibility. Common materials used in manufacturing spider couplings include:

- Aluminum: Aluminum is lightweight and corrosion-resistant, making it suitable for applications where weight reduction is important. It offers good mechanical properties and can be used in various industries.

- Steel: Steel provides excellent strength and durability. It’s often used in heavy-duty applications where high torque transmission is required. Surface treatments can enhance corrosion resistance.

- Stainless Steel: Stainless steel offers corrosion resistance in aggressive environments. It’s commonly used in industries such as food processing, pharmaceuticals, and chemical processing.

- Cast Iron: Cast iron is known for its high compressive strength and wear resistance. It’s suitable for applications requiring robust construction and can handle high torque loads.

- Plastic/Polymer: Certain polymers and plastics, such as polyurethane or nylon, are used for the elastomeric spider element. These materials provide flexibility, vibration dampening, and misalignment compensation.

The choice of materials depends on the specific requirements of the application. For example, aluminum or stainless steel may be chosen for industries requiring corrosion resistance, while steel or cast iron may be selected for heavy-duty applications. The elastomeric spider is typically made from a durable polymer to ensure flexibility and effective torque transmission while accommodating misalignment. Overall, selecting the right materials ensures that spider couplings can withstand the demands of the intended application and provide reliable performance over their lifespan.

What are the best practices for ensuring proper lubrication of spider couplings?

Proper lubrication is essential for maintaining the performance and lifespan of spider couplings. Here are some best practices to ensure proper lubrication:

- Use the Right Lubricant: Select a lubricant that is recommended by the coupling manufacturer. The lubricant should be compatible with the elastomeric spider material and the operating conditions of the machinery.

- Follow Manufacturer’s Guidelines: Adhere to the lubrication schedule and guidelines provided by the manufacturer. They will specify the appropriate lubrication intervals and the quantity of lubricant to be applied.

- Clean the Components: Before applying lubricant, make sure the coupling components are clean and free of dirt, debris, and old lubricant residues. Cleaning the components prevents contamination of the new lubricant.

- Apply Lubricant Evenly: Apply the lubricant evenly on all contact surfaces of the elastomeric spider and the coupling hub. Avoid over-lubrication, which can lead to excess buildup and potential slippage.

- Use Lubrication Tools: Some couplings may have lubrication ports or fittings that facilitate the application of lubricant. If such features are present, use the appropriate lubrication tools to ensure thorough coverage.

- Operate Coupling After Lubrication: After applying lubricant, operate the coupling for a short period to ensure that the lubricant is evenly distributed across the contact surfaces. This helps in preventing dry spots and optimizing lubrication effectiveness.

- Monitor Lubricant Condition: Regularly inspect the condition of the lubricant during routine maintenance checks. If you notice signs of contamination, degradation, or insufficient lubrication, take corrective actions promptly.

- Consider Operating Conditions: Environmental factors such as temperature, humidity, and exposure to chemicals can affect the performance of lubricants. Choose a lubricant that can withstand the specific operating conditions of the machinery.

- Document Lubrication Activities: Keep a record of lubrication activities, including the type of lubricant used, lubrication intervals, and the results of lubrication checks. This documentation helps track the history of lubrication and informs future maintenance decisions.

By following these best practices for lubrication, you can ensure that the elastomeric spider remains properly lubricated, reducing friction, wear, and the potential for premature coupling failure.

How do you properly install and maintain a spider coupling in machinery?

Installation:

Proper installation of a spider coupling is essential to ensure its optimal performance and longevity. Here are the steps for installing a spider coupling:

- Ensure Safety: Before starting any installation, make sure the machinery is properly shut down and all energy sources are disconnected.

- Inspect Components: Check the hubs, elastomeric spider, and shafts for any damage or debris. Ensure that the components match the correct specifications.

- Align Shafts: Align the shafts to minimize initial misalignment before inserting the elastomeric spider.

- Insert Spider: Place the elastomeric spider into one of the hubs, ensuring that the lobes or fins are correctly aligned with the grooves in the hub.

- Align Second Hub: Carefully align the second hub with the first one, making sure the spider lobes fit into the grooves of both hubs.

- Press Hubs Together: Gently press the hubs together until they meet. Avoid using excessive force, as this could damage the elastomeric spider.

- Check Alignment: After installation, check the alignment of the shafts and the coupling. Misalignment should not exceed the manufacturer’s recommended limits.

- Tighten Fasteners: Tighten the fasteners on the hubs according to the manufacturer’s torque specifications. Use a torque wrench to ensure proper tightening.

- Verify Clearance: Check for proper clearance between the coupling and surrounding components to prevent interference during operation.

- Run System: Start the machinery and monitor the coupling for any unusual vibrations or noise. Make any necessary adjustments if issues are detected.

Maintenance:

Maintaining a spider coupling is important to ensure its continued performance and prevent premature failure. Here are some maintenance tips:

- Regular Inspection: Periodically inspect the spider coupling for signs of wear, damage, or deterioration. Look for cracks, tears, or other abnormalities in the elastomeric spider.

- Clean Environment: Keep the coupling and surrounding area clean from dirt, debris, and contaminants that could impact its performance.

- Lubrication: Spider couplings are self-lubricating due to the elastomeric material. Avoid using additional lubricants, as they can deteriorate the elastomeric properties.

- Temperature Consideration: Be aware of the temperature range specified by the manufacturer for the elastomeric material. Extreme temperatures can affect the performance and lifespan of the coupling.

- Replace Worn Parts: If the elastomeric spider shows signs of wear, replace it with a new one from the manufacturer. Do not continue using a worn or damaged spider.

- Monitor Vibrations: Regularly monitor the machinery for unusual vibrations or noise, as these can indicate issues with the coupling. Address any problems promptly.

- Follow Manufacturer Guidelines: Adhere to the manufacturer’s recommended maintenance schedule and guidelines for the specific spider coupling model.

Proper installation and regular maintenance contribute to the reliable and efficient operation of a spider coupling in machinery.

editor by CX 2024-04-22

China wholesaler 2017 Gr PU Rubber Spider / Shaft Coupling

Product Description

Product description

|

Material |

Materials for silicon,fluorine,NBR,FPM,EPDM,SILCONE ACM,HNBR |

| Inspection Equipments | Excellent chemical and physical property, excellent oil- resistance, high temperature stability, etc. |

| Tolerance | +/-0.05mm |

| Drawing Format | PDF/DWG/DXF/IGS/STEP,etc |

| Application field | Parts are used on vehicles, printing machines, food processing machines, textile machines, electronic machines, etc. |

| Manufacturing process | CNC machining Broaching, Drilling, Milling, Other Machining Services, Rapid Prototyping, Turning, |

| Shape | As per your drawing Or your sample |

| Color service | Customization |

| QC inspection |

Make sure 100% inspection before the delivery |

| Advantages | Maintenance,acturally HRC coupling doesn’t need maintenance. |

| Environmental, elastic components make HRC coupling applies to a variety of working conditions. | |

|

Reliable transmission, in case of elastic component is damaged, the dog segment wichcasted siamesedly still keep the transmission processing reliably. |

|

|

Economic, HRC couplings have already been made of optimization design,which make transmission power match the transmission shaft diameter. |

|

| Good recovery capacity, elastic components can reduce the load at the CHINAMFG moments, and the deviation is a major consideration when designing. | |

|

Adaptability of misalignment, HRC can coupling contains parallel shift, angle shift and axis shift which happen some times. |

Application and analysis

Our warehouse

Custom rubber parts

Custom plastic parts

Packing & Delivery

Packaging Details: plastic bag packing inside, carton packing outside, or customized packing.

Port:Xihu (West Lake) Dis.g port, ZheJiang city.

Lead Time :

| Quantity(Pieces) | 1 – 1000 | 1001 – 10000 | 10001 – 50000 | >50000 |

| Est. Time(days) | 5 | 12 | 18 | To be negotiated |

Place order steps

Our Services:

1. Convenient: 24th Hours sales/After-sales Service online or on the phone.

2. Quality Assurance: We will discuss with you and supply you the best quality comfortable to your market.

3. Quick delivery: Time is money, we promise we always will deliver the goods quicker than others.

4. According to customers’ drawing,customized specifications are welcomed.

5. Small orders can be accepted.

Packing

Company Profile

SHEN ZHOU CHINAMFG RUBBER & PLASTIC CO.,LTD was founded in 2000. The factory located in industrial zone of HangZhou city, ZheJiang province, china.

We have Plastic injection molding workshop and rubber compression molding workshops.Our main products includes Bakelit Knobs,Pull Handle,rubber door stops, door guard, roller, rubber bumpers, Rubber grommets, vibration dampers, seals, plastic corner, injection plastic brackets, injection plastic shell.to undertake various kinds of rubber molding and plastic injection parts, customize according to drawing and samples.

The products have been exported to America, Europe, Oceania, Middle East, Southeast Asia and other regions and countries, and hope to build more business Cooperation with new client from all over the world.

FAQ

Q1: Are you a manufacturer or a trading company?

A1: We are the original manufacturer of custom rubber parts and custom plastic parts.

Q2: Where is your company located?

A2: Our company is located in HangZhou City, ZheJiang Province, China.

Q3: Could I get free samples?

A3: We could provide small samples for free, but air freight or sea freight should be borne by customer side.

Q4: What should I provide in order to get an offer?

A4: Customers are required to provide material, inner diameter, outer diameter, cross section distance and quantity.

Q5: How is the goods packed by your factory?

A5: The goods are normally packed by plastic bags, carton boxes with pallets or wooden boxes.

Q6: What are the incoterms applied?

A6: The incoterms applied are FOB, CIF and CFR.

Q7: What are the payment terms accepted?

A7: We accept Alibaba Trade Assurance, T/T, L/C and West Union.

Q8: What about the delivery time?

A8: The goods are normally dellivered to customer side within 7-30 days based CHINAMFG the mode of transport required.

/* March 10, 2571 17:59:20 */!function(){function s(e,r){var a,o={};try{e&&e.split(“,”).forEach(function(e,t){e&&(a=e.match(/(.*?):(.*)$/))&&1

Are there any industry standards or guidelines for designing and using spider couplings?

Yes, there are industry standards and guidelines that provide recommendations for designing, selecting, and using spider couplings in various mechanical systems. These standards help ensure the safe and reliable operation of spider couplings in industrial applications. Some of the relevant standards include:

- AGMA 9002-B15: This American Gear Manufacturers Association (AGMA) standard provides guidelines for the selection and application of flexible couplings, including spider couplings. It covers topics such as coupling types, misalignment, torque capacity, and lubrication.

- ISO 14691: This International Organization for Standardization (ISO) standard specifies methods for testing the torsional stiffness of flexible couplings, including spider couplings. It outlines procedures for determining the dynamic torsional stiffness and related parameters.

- API 671: This American Petroleum Institute (API) standard provides guidelines for special-purpose couplings used in petroleum, chemical, and gas industry services. It covers design, manufacturing, inspection, and testing requirements for couplings, including those with elastomeric elements.

While these standards offer valuable insights, it’s important to note that specific industry requirements and applications may influence the design and selection of spider couplings. Manufacturers, engineers, and designers should also consider factors such as torque, misalignment compensation, environment, and system dynamics when applying these standards to their designs. Adhering to industry standards ensures that spider couplings are properly designed, installed, and used to meet the intended performance and safety criteria.

Are there any specific maintenance practices for ensuring the longevity of spider couplings?

Yes, implementing proper maintenance practices is crucial for ensuring the longevity and optimal performance of spider couplings. Here are some specific maintenance practices to consider:

- Regular Inspections: Conduct routine visual inspections of the coupling to identify any signs of wear, damage, or misalignment. Regular inspections allow you to detect issues early and address them before they escalate.

- Lubrication: Follow the manufacturer’s recommendations for lubrication intervals and use the appropriate lubricant. Proper lubrication reduces friction, prevents excessive wear, and maintains coupling efficiency.

- Alignment Checks: Ensure that the shafts connected by the coupling are properly aligned. Misalignment can accelerate wear and compromise coupling performance. Regular alignment checks are essential, especially after maintenance or changes in operating conditions.

- Torque Checks: Periodically check the torque values of fasteners such as bolts, nuts, and screws that secure the coupling components. Proper torque ensures the coupling remains securely fastened.

- Temperature Monitoring: Monitor the operating temperature of the coupling during normal operation. Abnormally high temperatures can indicate excessive friction and potential issues with the coupling.

- Environmental Considerations: If the machinery is operating in harsh or corrosive environments, take appropriate measures to protect the coupling from contaminants, chemicals, and moisture.

- Replacement of Elastomeric Spider: The elastomeric spider is a critical component of the coupling. Replace it if you notice signs of wear, cracks, tears, or deformation. Follow the manufacturer’s recommended replacement intervals.

- Documentation: Maintain records of maintenance activities, inspections, and any repairs performed on the coupling. This documentation helps track the history of the coupling and informs future maintenance decisions.

- Training and Education: Ensure that maintenance personnel are trained in proper coupling maintenance practices. This includes handling, installation, and lubrication procedures.

By adhering to these maintenance practices, you can extend the lifespan of spider couplings, reduce the likelihood of unexpected failures, and ensure the continued reliability of machinery systems.

What is a spider coupling and how is it used in mechanical systems?

A spider coupling, also known as a jaw coupling or elastomeric coupling, is a type of flexible coupling used to connect two shafts while accommodating misalignment and transmitting torque between them. It consists of three main components: two hubs and an elastomeric spider or insert that fits between them.

The elastomeric spider is typically made of a flexible and durable material, such as rubber or polyurethane, with a series of lobes or fins that fit into matching grooves on the inner surfaces of the hubs. These lobes allow the spider to flex and absorb misalignments between the connected shafts while transmitting torque.

The spider coupling is used in mechanical systems to:

- Transmit Torque: The primary function of a spider coupling is to transmit torque from one shaft to another. As the shafts rotate, the elastomeric spider deforms slightly, allowing the hubs to move relative to each other while maintaining torque transmission.

- Accommodate Misalignment: Spider couplings can accommodate different types of misalignment, including angular, axial, and parallel misalignments, without causing excessive stress on the connected components. This flexibility helps prevent premature wear and failure.

- Dampen Vibrations: The elastomeric material of the spider acts as a shock absorber, dampening vibrations and reducing the transmission of vibrations between the connected shafts. This can improve overall system performance and reduce wear on components.

- Isolate Shock Loads: In applications with sudden changes in torque or shock loads, the spider coupling can absorb and dampen these shocks, protecting the connected components from damage.

- Reduce Maintenance: Spider couplings require minimal maintenance due to their simple design and absence of lubrication points. This can lead to reduced downtime and maintenance costs in industrial machinery.

- Provide Electric Insulation: Spider couplings can provide electrical isolation between the connected shafts, making them suitable for applications where electrical grounding needs to be minimized.

Spider couplings are commonly used in various machinery and equipment, such as pumps, compressors, conveyors, fans, and industrial machinery. They are particularly well-suited for applications that require flexibility, misalignment compensation, vibration reduction, and ease of maintenance.

editor by CX 2024-01-23

China wholesaler Stainless Steel Coupling Transmission Machined Parts Gear Roller Chain Couplings Nm Mh Flange Elastic Spider Disc Elastomeric Rigid Jaw Flexible Shaft Coupling

Product Description

Stainless Steel Coupling Transmission Parts Gear High Quality Good Price Gear Roller Chain Couplings Nm Flange Flexible Elastomeric Stainless Steel Coupling

We are the leading top Chinese coupling manufacturer, and are specializing in various high quality coupling.

1. Material: Cast iron, Rubber.

2. OEM and ODM are available

3. High efficient in transmission

4. Finishing: Painted.

5. High quality with competitive price

6. Different models suitable for your different demands

7. Stock for different bore size on both sides available.

8. Application in wide range of environment.

9. Quick and easy mounting and disassembly.

10. Resistant to oil and electrical insulation.

11. Identical clockwise and anticlockwise rotational characteristics.

12. Small dimension, low weight, high transmitted torque.

13. It has good performance on compensating the misalignment.

Fluid couplings:

Features:

Improve the starting capability of electric motor, protect motor against overloading, damp shock, load

fluctuation and torsional vibration, and balance and load distribution in case of multimotor drives.

Applications:

Belt conveyers, csraper conveyers, and conveyers of all kinds Bucket elevators, ball mills, hoisters, crushers,

excavators, mixers, straighteners, cranes, etc.

Flange Flexible Coupling:

Flexible Coupling Model is widely used for its compact designing,easy installation,convenientmaintenance,small size and

light weight.As long as the’relative displacement between shafts is kept within the specified tolerance,the coupling will

operate the best function and a longer working life,thus it is greatly demanded in medium and minorpower transmission

systems drive by moters,such as speed reducers,hoists,compressor,spining &weaving machines and ball mills,permittable

relative displacement:Radial displacement 0.2-0.6mm ; Angel displacemente 0o 30′–1o 30′

Jaw Couplings:

Click here for more types of couplings

Our Services:

1.Design Services

Our design team has experience in cardan shaft relating to product design and development. If you have any needs for your new product or wish to make further improvements, we are here to offer our support.

2.Product Services

raw materials → Cutting → Forging →Rough machining →Shot blasting →Heat treatment →Testing →Fashioning →Cleaning→ Assembly→Packing→Shipping

3.Samples Procedure

We could develop the sample according to your requirement and amend the sample constantly to meet your need.

4.Research & Development

We usually research the new needs of the market and develop the new model when there is new cars in the market.

5.Quality Control

Every step should be special test by Professional Staff according to the standard of ISO9001 and TS16949.

Company Information:

/* March 10, 2571 17:59:20 */!function(){function s(e,r){var a,o={};try{e&&e.split(“,”).forEach(function(e,t){e&&(a=e.match(/(.*?):(.*)$/))&&1

What are the common challenges associated with spider coupling misalignment and how can they be addressed?

Misalignment is a common challenge in spider couplings that can lead to reduced efficiency, increased wear, and potential coupling failure. Here are the common challenges associated with misalignment and how they can be addressed:

- Reduced Torque Transmission: Misalignment can decrease the effective torque transmitted between the shafts, leading to inefficiency and potential overload. Regularly check and align the shafts according to the manufacturer’s recommendations to ensure proper torque transmission.

- Vibration and Noise: Misalignment can cause excessive vibrations and noise in the machinery. Implement precision alignment techniques during installation to minimize misalignment-induced vibrations and noise.

- Increased Wear: Misalignment results in uneven loading on the elastomeric spider, causing premature wear and potential failure. Regularly inspect the coupling for signs of wear and replace the elastomeric spider if necessary. Address misalignment promptly to prevent excessive wear.

- Heat Generation: Misalignment can generate heat due to friction between the elastomeric spider and the hubs. This can lead to accelerated wear and reduced coupling lifespan. Proper alignment helps minimize heat generation and associated issues.

- Shaft Fatigue: Severe misalignment can induce shaft fatigue and stress concentrations, leading to shaft failure over time. Avoid excessive misalignment and ensure that the coupling is properly aligned during installation.

- Reduced Service Life: Misalignment puts additional stress on the elastomeric spider, reducing its service life. Proper alignment and maintenance practices can extend the service life of the coupling.

- Performance Variations: Misalignment can lead to variations in performance and inconsistent operation of the machinery. Regularly monitor the coupling’s performance and address any issues promptly to ensure consistent operation.

To address these challenges, it’s crucial to prioritize precision alignment during the installation of the spider coupling. Follow the manufacturer’s guidelines for alignment tolerances and use alignment tools and techniques to achieve accurate alignment. Regular maintenance, including inspections and alignment checks, will help mitigate the negative effects of misalignment and ensure the reliable performance of spider couplings in industrial applications.

What are the symptoms of spider coupling wear or deterioration, and how can they be identified?

Spider couplings, like other mechanical components, can experience wear and deterioration over time due to factors such as torque, misalignment, and environmental conditions. Identifying the symptoms of wear is crucial for maintaining coupling performance and preventing unexpected failures. Here are some common symptoms of spider coupling wear and deterioration:

- Vibration and Noise: Increased vibration or unusual noise during operation can indicate wear in the spider coupling. Excessive wear can lead to reduced dampening of vibrations and increased noise levels.

- Reduced Torque Transmission: If the coupling is no longer transmitting torque efficiently, it may indicate wear or damage to the elastomeric spider. Reduced torque transmission can result in decreased equipment performance.

- Visible Cracks or Tears: Inspect the elastomeric spider for visible cracks, tears, or signs of deformation. These issues can lead to uneven load distribution and compromised coupling function.

- Uneven Shaft Movement: Misalignment caused by wear can lead to uneven movement of connected shafts. This can be observed through irregular motion or wobbling during operation.

- Increased Heat Generation: If the coupling is generating more heat than usual, it may indicate excessive friction due to wear. Overheating can accelerate wear and affect coupling performance.

- Irregular Performance: If machinery or equipment connected by the coupling experiences irregular or unpredictable behavior, it could be a sign of coupling wear affecting torque transmission.

To identify these symptoms, regular visual inspections, vibration analysis, and performance monitoring are recommended. If any of these symptoms are observed, it’s advisable to replace the worn or damaged spider coupling with a new one. Routine maintenance and timely replacement can help ensure the continued reliability and performance of spider couplings in mechanical systems.

What is a spider coupling and how is it used in mechanical systems?

A spider coupling, also known as a jaw coupling or elastomeric coupling, is a type of flexible coupling used to connect two shafts while accommodating misalignment and transmitting torque between them. It consists of three main components: two hubs and an elastomeric spider or insert that fits between them.

The elastomeric spider is typically made of a flexible and durable material, such as rubber or polyurethane, with a series of lobes or fins that fit into matching grooves on the inner surfaces of the hubs. These lobes allow the spider to flex and absorb misalignments between the connected shafts while transmitting torque.

The spider coupling is used in mechanical systems to:

- Transmit Torque: The primary function of a spider coupling is to transmit torque from one shaft to another. As the shafts rotate, the elastomeric spider deforms slightly, allowing the hubs to move relative to each other while maintaining torque transmission.

- Accommodate Misalignment: Spider couplings can accommodate different types of misalignment, including angular, axial, and parallel misalignments, without causing excessive stress on the connected components. This flexibility helps prevent premature wear and failure.

- Dampen Vibrations: The elastomeric material of the spider acts as a shock absorber, dampening vibrations and reducing the transmission of vibrations between the connected shafts. This can improve overall system performance and reduce wear on components.

- Isolate Shock Loads: In applications with sudden changes in torque or shock loads, the spider coupling can absorb and dampen these shocks, protecting the connected components from damage.

- Reduce Maintenance: Spider couplings require minimal maintenance due to their simple design and absence of lubrication points. This can lead to reduced downtime and maintenance costs in industrial machinery.

- Provide Electric Insulation: Spider couplings can provide electrical isolation between the connected shafts, making them suitable for applications where electrical grounding needs to be minimized.

Spider couplings are commonly used in various machinery and equipment, such as pumps, compressors, conveyors, fans, and industrial machinery. They are particularly well-suited for applications that require flexibility, misalignment compensation, vibration reduction, and ease of maintenance.

editor by CX 2024-01-15

China wholesaler Transmission Parts Jaw Coupling Aluminum Flexible Plum Shaft Coupling with Spider

Product Description

Excellent powder metallurgy parts metallic sintered parts

We could offer various powder metallurgy parts including iron based and copper based with top quality and cheapest price, please only send the drawing or sample to us, we will according to customer’s requirement to make it. if you are interested in our product, please do not hesitate to contact us, we would like to offer the top quality and best service for you. thank you!

How do We Work with Our Clients

1. For a design expert or a big company with your own engineering team: we prefer to receive a fully RFQ pack from you including drawing, 3D model, quantity, pictures;

2. For a start-up company owner or green hand for engineering: just send an idea that you want to try, you don’t even need to know what casting is;

3. Our sales will reply you within 24 hours to confirm further details and give the estimated quote time;

4. Our engineering team will evaluate your inquiry and provide our offer within next 1~3 working days.

5. We can arrange a technical communication meeting with you and our engineers together anytime if required.

| Place of origin: | Jangsu,China |

| Type: | Powder metallurgy sintering |

| Spare parts type: | Powder metallurgy parts |

| Machinery Test report: | Provided |

| Material: | Iron,stainless,steel,copper |

| Key selling points: | Quality assurance |

| Mould type: | Tungsten steel |

| Material standard: | MPIF 35,DIN 3571,JIS Z 2550 |

| Application: | Small home appliances,Lockset,Electric tool, automobile, |

| Brand Name: | OEM SERVICE |

| Plating: | Customized |

| After-sales Service: | Online support |

| Processing: | Powder Metallurgr,CNC Machining |

| Powder Metallurgr: | High frequency quenching, oil immersion |

| Quality Control: | 100% inspection |

The Advantage of Powder Metallurgy Process

1. Cost effective

The final products can be compacted with powder metallurgy method ,and no need or can shorten the processing of machine .It can save material greatly and reduce the production cost .

2. Complex shapes

Powder metallurgy allows to obtain complex shapes directly from the compacting tooling ,without any machining operation ,like teeth ,splines ,profiles ,frontal geometries etc.

3. High precision

Achievable tolerances in the perpendicular direction of compacting are typically IT 8-9 as sintered,improvable up to IT 5-7 after sizing .Additional machining operations can improve the precision .

4. Self-lubrication

The interconnected porosity of the material can be filled with oils ,obtaining then a self-lubricating bearing :the oil provides constant lubrication between bearing and shaft ,and the system does not need any additional external lubricant .

5. Green technology

The manufacturing process of sintered components is certified as ecological ,because the material waste is very low ,the product is recyclable ,and the energy efficiency is good because the material is not molten.

FAQ

Q1: What is the type of payment?

A: Usually you should prepay 50% of the total amount. The balance should be pay off before shipment.

Q2: How to guarantee the high quality?

A: 100% inspection. We have Carl Zeiss high-precision testing equipment and testing department to make sure every product of size,appearance and pressure test are good.

Q3: How long will you give me the reply?

A: we will contact you in 12 hours as soon as we can.

Q4. How about your delivery time?

A: Generally, it will take 25 to 35 days after receiving your advance payment. The specific delivery time depends on the items and the quantity of your order. and if the item was non standard, we have to consider extra 10-15days for tooling/mould made.

Q5. Can you produce according to the samples or drawings?

A: Yes, we can produce by your samples or technical drawings. We can build the molds and fixtures.

Q6: How about tooling Charge?

A: Tooling charge only charge once when first order, all future orders would not charge again even tooling repair or under maintance.

Q7: What is your sample policy?

A: We can supply the sample if we have ready parts in stock, but the customers have to pay the sample cost and the courier cost.

Q8: How do you make our business long-term and good relationship?

A: 1. We keep good quality and competitive price to ensure our customers benefit ;

2. We respect every customer as our friend and we sincerely do business and make friends with them, no matter where they come from.

/* March 10, 2571 17:59:20 */!function(){function s(e,r){var a,o={};try{e&&e.split(“,”).forEach(function(e,t){e&&(a=e.match(/(.*?):(.*)$/))&&1

What materials are typically used in manufacturing spider couplings and why?

Spider couplings are constructed using a combination of materials to achieve durability, flexibility, and efficient torque transmission. The choice of materials depends on factors such as application requirements, environmental conditions, and the desired balance between strength and flexibility. Common materials used in manufacturing spider couplings include:

- Aluminum: Aluminum is lightweight and corrosion-resistant, making it suitable for applications where weight reduction is important. It offers good mechanical properties and can be used in various industries.

- Steel: Steel provides excellent strength and durability. It’s often used in heavy-duty applications where high torque transmission is required. Surface treatments can enhance corrosion resistance.

- Stainless Steel: Stainless steel offers corrosion resistance in aggressive environments. It’s commonly used in industries such as food processing, pharmaceuticals, and chemical processing.

- Cast Iron: Cast iron is known for its high compressive strength and wear resistance. It’s suitable for applications requiring robust construction and can handle high torque loads.

- Plastic/Polymer: Certain polymers and plastics, such as polyurethane or nylon, are used for the elastomeric spider element. These materials provide flexibility, vibration dampening, and misalignment compensation.

The choice of materials depends on the specific requirements of the application. For example, aluminum or stainless steel may be chosen for industries requiring corrosion resistance, while steel or cast iron may be selected for heavy-duty applications. The elastomeric spider is typically made from a durable polymer to ensure flexibility and effective torque transmission while accommodating misalignment. Overall, selecting the right materials ensures that spider couplings can withstand the demands of the intended application and provide reliable performance over their lifespan.

What are the best practices for ensuring proper lubrication of spider couplings?

Proper lubrication is essential for maintaining the performance and lifespan of spider couplings. Here are some best practices to ensure proper lubrication:

- Use the Right Lubricant: Select a lubricant that is recommended by the coupling manufacturer. The lubricant should be compatible with the elastomeric spider material and the operating conditions of the machinery.

- Follow Manufacturer’s Guidelines: Adhere to the lubrication schedule and guidelines provided by the manufacturer. They will specify the appropriate lubrication intervals and the quantity of lubricant to be applied.

- Clean the Components: Before applying lubricant, make sure the coupling components are clean and free of dirt, debris, and old lubricant residues. Cleaning the components prevents contamination of the new lubricant.

- Apply Lubricant Evenly: Apply the lubricant evenly on all contact surfaces of the elastomeric spider and the coupling hub. Avoid over-lubrication, which can lead to excess buildup and potential slippage.

- Use Lubrication Tools: Some couplings may have lubrication ports or fittings that facilitate the application of lubricant. If such features are present, use the appropriate lubrication tools to ensure thorough coverage.

- Operate Coupling After Lubrication: After applying lubricant, operate the coupling for a short period to ensure that the lubricant is evenly distributed across the contact surfaces. This helps in preventing dry spots and optimizing lubrication effectiveness.

- Monitor Lubricant Condition: Regularly inspect the condition of the lubricant during routine maintenance checks. If you notice signs of contamination, degradation, or insufficient lubrication, take corrective actions promptly.

- Consider Operating Conditions: Environmental factors such as temperature, humidity, and exposure to chemicals can affect the performance of lubricants. Choose a lubricant that can withstand the specific operating conditions of the machinery.

- Document Lubrication Activities: Keep a record of lubrication activities, including the type of lubricant used, lubrication intervals, and the results of lubrication checks. This documentation helps track the history of lubrication and informs future maintenance decisions.

By following these best practices for lubrication, you can ensure that the elastomeric spider remains properly lubricated, reducing friction, wear, and the potential for premature coupling failure.

What is a spider coupling and how is it used in mechanical systems?

A spider coupling, also known as a jaw coupling or elastomeric coupling, is a type of flexible coupling used to connect two shafts while accommodating misalignment and transmitting torque between them. It consists of three main components: two hubs and an elastomeric spider or insert that fits between them.

The elastomeric spider is typically made of a flexible and durable material, such as rubber or polyurethane, with a series of lobes or fins that fit into matching grooves on the inner surfaces of the hubs. These lobes allow the spider to flex and absorb misalignments between the connected shafts while transmitting torque.

The spider coupling is used in mechanical systems to:

- Transmit Torque: The primary function of a spider coupling is to transmit torque from one shaft to another. As the shafts rotate, the elastomeric spider deforms slightly, allowing the hubs to move relative to each other while maintaining torque transmission.

- Accommodate Misalignment: Spider couplings can accommodate different types of misalignment, including angular, axial, and parallel misalignments, without causing excessive stress on the connected components. This flexibility helps prevent premature wear and failure.

- Dampen Vibrations: The elastomeric material of the spider acts as a shock absorber, dampening vibrations and reducing the transmission of vibrations between the connected shafts. This can improve overall system performance and reduce wear on components.

- Isolate Shock Loads: In applications with sudden changes in torque or shock loads, the spider coupling can absorb and dampen these shocks, protecting the connected components from damage.

- Reduce Maintenance: Spider couplings require minimal maintenance due to their simple design and absence of lubrication points. This can lead to reduced downtime and maintenance costs in industrial machinery.

- Provide Electric Insulation: Spider couplings can provide electrical isolation between the connected shafts, making them suitable for applications where electrical grounding needs to be minimized.

Spider couplings are commonly used in various machinery and equipment, such as pumps, compressors, conveyors, fans, and industrial machinery. They are particularly well-suited for applications that require flexibility, misalignment compensation, vibration reduction, and ease of maintenance.

editor by CX 2024-01-12

China wholesaler Star Type Spider Jaw Coupling Flexible Rubber Shaft Coupling

Product Description

Star Type Spider Jaw Coupling Flexible Rubber Shaft Coupling

Product Description

XL Flexible Coupling Flange -Type Star comprises a convex claw block can be avoided due to external constraints, internal deformation and centrifugal impact deformation; concave convex claw, the pressure on the surface of the involute tooth is very small, even under overload, the tooth will not wear or deformation.

Product Parameters

Features

The polyurethane elastomer is limited by convex claw block, which can avoid the internal deformation and external deformation caused by centrifugal force.

The concave surface with large claw makes the surface pressure on involute tooth very small.

Even if the tooth is overloaded, the tooth will not wear or deform.

It can compensate the displacement between the 2 transmission shafts well, and it is widely used.

Packaging & Shipping

Company Profile

HangZhou CHINAMFG machinery technology Co., Ltd is an industry transmission solutions manufacuturer and service provider.

We offer 1 stop solution for power transmission products for different factories, such as chemicals, energy, material handling, environmental, extraction, pulp and paper, steel and metal, food and beverage, and construction industries.

We supply: Customised gears, Small gearmotors, Industrial gearboxes, Motors, Brand product sourcing.

We offer renowned brand sourcing serivice for customers, such as Flender, SEW, ABB, Siemens, HYDAC, Parker, etc.

Our industrial Gear, Gearbox, gearmotor and motor are sold to more than 30 countries. High quality, good price, in time response and sincere service are our value and promises. We aim at making happy cooperation with our customers, bring them reliable and comfortable service.

/* March 10, 2571 17:59:20 */!function(){function s(e,r){var a,o={};try{e&&e.split(“,”).forEach(function(e,t){e&&(a=e.match(/(.*?):(.*)$/))&&1

What materials are typically used in manufacturing spider couplings and why?

Spider couplings are constructed using a combination of materials to achieve durability, flexibility, and efficient torque transmission. The choice of materials depends on factors such as application requirements, environmental conditions, and the desired balance between strength and flexibility. Common materials used in manufacturing spider couplings include:

- Aluminum: Aluminum is lightweight and corrosion-resistant, making it suitable for applications where weight reduction is important. It offers good mechanical properties and can be used in various industries.

- Steel: Steel provides excellent strength and durability. It’s often used in heavy-duty applications where high torque transmission is required. Surface treatments can enhance corrosion resistance.

- Stainless Steel: Stainless steel offers corrosion resistance in aggressive environments. It’s commonly used in industries such as food processing, pharmaceuticals, and chemical processing.

- Cast Iron: Cast iron is known for its high compressive strength and wear resistance. It’s suitable for applications requiring robust construction and can handle high torque loads.

- Plastic/Polymer: Certain polymers and plastics, such as polyurethane or nylon, are used for the elastomeric spider element. These materials provide flexibility, vibration dampening, and misalignment compensation.

The choice of materials depends on the specific requirements of the application. For example, aluminum or stainless steel may be chosen for industries requiring corrosion resistance, while steel or cast iron may be selected for heavy-duty applications. The elastomeric spider is typically made from a durable polymer to ensure flexibility and effective torque transmission while accommodating misalignment. Overall, selecting the right materials ensures that spider couplings can withstand the demands of the intended application and provide reliable performance over their lifespan.

Are there any specific maintenance practices for ensuring the longevity of spider couplings?

Yes, implementing proper maintenance practices is crucial for ensuring the longevity and optimal performance of spider couplings. Here are some specific maintenance practices to consider:

- Regular Inspections: Conduct routine visual inspections of the coupling to identify any signs of wear, damage, or misalignment. Regular inspections allow you to detect issues early and address them before they escalate.

- Lubrication: Follow the manufacturer’s recommendations for lubrication intervals and use the appropriate lubricant. Proper lubrication reduces friction, prevents excessive wear, and maintains coupling efficiency.

- Alignment Checks: Ensure that the shafts connected by the coupling are properly aligned. Misalignment can accelerate wear and compromise coupling performance. Regular alignment checks are essential, especially after maintenance or changes in operating conditions.

- Torque Checks: Periodically check the torque values of fasteners such as bolts, nuts, and screws that secure the coupling components. Proper torque ensures the coupling remains securely fastened.

- Temperature Monitoring: Monitor the operating temperature of the coupling during normal operation. Abnormally high temperatures can indicate excessive friction and potential issues with the coupling.

- Environmental Considerations: If the machinery is operating in harsh or corrosive environments, take appropriate measures to protect the coupling from contaminants, chemicals, and moisture.

- Replacement of Elastomeric Spider: The elastomeric spider is a critical component of the coupling. Replace it if you notice signs of wear, cracks, tears, or deformation. Follow the manufacturer’s recommended replacement intervals.

- Documentation: Maintain records of maintenance activities, inspections, and any repairs performed on the coupling. This documentation helps track the history of the coupling and informs future maintenance decisions.

- Training and Education: Ensure that maintenance personnel are trained in proper coupling maintenance practices. This includes handling, installation, and lubrication procedures.

By adhering to these maintenance practices, you can extend the lifespan of spider couplings, reduce the likelihood of unexpected failures, and ensure the continued reliability of machinery systems.

Are there different types of spider couplings available for various uses?

Yes, there are different types of spider couplings available to suit various industrial applications and requirements. These variations in design and material offer flexibility in choosing the right coupling for specific uses. Here are some common types of spider couplings:

- Standard Jaw Couplings: These couplings feature a simple design with two hubs and an elastomeric spider. They are suitable for general-purpose applications that require misalignment compensation and torque transmission.

- Curved Jaw Couplings: These couplings have curved lobes on the elastomeric spider, allowing for increased misalignment compensation and dampening of vibrations. They offer higher torque capacity and are commonly used in pumps, compressors, and conveyors.

- Spider Couplings with Spacer: These couplings include a spacer between the hubs, allowing for greater axial misalignment compensation. They are used in applications with longer distances between shafts.

- Lovejoy Couplings: Lovejoy couplings are a specific brand of spider couplings known for their high torque capacity, durability, and ease of installation. They come in various styles, including standard, curved jaw, and split type.

- Bowex Couplings: Bowex couplings are designed for applications with high torque requirements and aggressive operating conditions. They offer excellent misalignment compensation and are used in heavy-duty machinery.

- Insert Material Variations: Spider couplings come with elastomeric inserts made from various materials such as rubber, polyurethane, and thermoplastic. These materials offer different levels of flexibility, temperature resistance, and chemical resistance.

- Electrically Insulating Spider Couplings: Some spider couplings are designed with electrically insulating materials to prevent electrical current transmission between shafts. These couplings are used in applications where electrical isolation is critical.

The choice of spider coupling type depends on factors such as torque requirements, misalignment compensation needed, operating conditions, and industry-specific requirements. Proper selection ensures optimal performance, extended equipment lifespan, and reduced maintenance needs.

editor by CX 2023-12-25

High China torque gearbox belt drive parallel shaft reduction gearbox zq 500 zq500 speed reducer for crane – Supplier Manufacturer wholesaler Factory

For far more details.: Cell/Whatpp: +8613083988828

Shut up of shear pin which will shear in 50 percent if the put into action is subject matter to enough resistance Shear pin: the shear pin shaft I use for the chipper/shredder. The pushed finish yoke is in fact two pieces with a shear pin or bolt that holds the two parts as one particular for the duration of procedure. Need to the tools encounter a unexpected end the pin will take the shock and “shear off” avoiding any driveline injury. EPG Transmission provides efficiency and ease and comfort to the agriculture industry. Our totally automatic transmissions supply the overall performance and maneuverability that you need in off-highway operation, specifically in difficult environments.We can source a total-selection of energy transmission products like chains, sprockets and plate wheels, pulleys, gearboxes, motors, couplings, gears and racks pto shaft, agricultural gearboxes. EPG is willing to cooperate sincerely and produce typically with close friends!

Overview

Quick Specifics

- Relevant Industries:

-

Manufacturing Plant

- Brand name Title:

-

OEM

- Item NO:

-

SYF

- Rated Electrical power:

-

.twelve~200kw

- Solution title:

-

JZQ gear box

- Merchandise Search phrases:

-

gearbox for metallic flattening machine

- Coloration:

-

GreenBlueCustom

- ZQ Reducer gearbox:

-

ZQ Reducer

- gearbox:

-

Reducer gearbox

- gearbox for substance:

-

gearbox for dryer

- Equipment speed gearbox:

-

Zq equipment speed gearbox

- Material:

-

45C Metal

Packaging & Supply

-

Guide Time

: -

Amount(Items) one – a hundred >100 Est. Time(days) twenty To be negotiated

On the internet Customization

Item Description

ZQ Cylindrical equipment gearbox gear carburizing, quenching, grinding, higher bearing ability, low sounds largely employed for belt conveyor and a variety of sorts of transportation equipment, can also be used to push other common equipment. It has the benefits of higher bearing ability, long services lifestyle, little volume, higher effectiveness, light excess weight, for the input shaft and the output shaft is vertically arranged in the driving system.

The discipline of cylindrical gear gearbox is extensively utilized in metallurgical products, mining products, automation equipment, food equipment, packaging equipment, tobacco products and many others..

|

Specification |

Manufacturing Potential(t/h) |

Motor Electricity (kw) |

Pulley Pace (r/min) |

Gearbox Design |

Weight(t) |

|

Φ0.6×8 m |

one.five-2.eight |

4 |

8 |

JZQ 250-16- Ⅰ |

5.one |

|

Φ0.8×10 m |

three |

four |

7.five |

JZQ 350-16- Ⅰ |

six.9 |

|

Φ10×10 m |

three.three-4.nine |

5.5 |

5.8 |

JZQ 400-sixteen- Ⅰ |

seven.5 |

|

Φ1.2×10 m |

4-6 |

seven.five |

4.eight |

ZL 50-16- Ⅰ |

13.5 |

|

Φ1.5×12 m |

4-six |

ten |

4.8 |

JZQ 500- Ⅲ-2F |

eighteen.9 |

|

Φ1.5×15 m |

seven-12 |

18.five |

4.8 |

ZQ 500- Ⅲ-2F |

21 |

|

Φ1.8×12 m |

seven-12 |

18.five |

four.1 |

JZQ 50-16 Ⅱ-2 |

22.eighty three |

|

Φ2.2×12 m |

twelve |

eighteen.5 |

three.two |

JZQ 650- Ⅲ |

37.6 |

|

Φ2.2×14 m |

twelve |

22 |

3.2 |

JZQ 650- Ⅲ |

40 |

|

Φ2.2×16 m |

ten-13 |

thirty |

three.2 |

JZQ 750- Ⅲ |

45 |

|

Φ2.4×14 m |

10-14 |

30 |

three |

JZQ 750- Ⅲ |

fifty one |

|

Φ2.4×18 m |

twenty five |

37 |

three |

ZL85-13-Ⅰ |

54 |

|

Φ2.4×20 m |

32-36 |

37 |

three |

ZL 85-thirteen- Ⅰ |

fifty four.14 |

|

Φ3×20 m |

forty-fifty |

fifty five |

2.fifty nine |

ZL 100-sixteen- Ⅰ |

seventy eight |

|

Φ3×25 m |

45-fifty eight |

75 |

two.59 |

ZL 100-sixteen-I |

104.nine |

Zq Cylindrical equipment pace gearbox

Zq Cylindrical equipment speed gearbox is a 3-stage transmission of involute cylindrical equipment gearbox, largely utilised inmining, metallurgy, cement, construction, chemical sector, gentle industry, etc all types of mechanical equipment, reduction generate, is suited for the workplace becoming limited by the composition adopts the vertical set up, substantial-velocity spindle speed not much more than 1500 r/min, the operate setting to + 40 °C and forty °C -, can optimistic &unfavorable procedure.

Principal Functions

1.gear with higher toughness and minimal carbon alloy steel by carburizing quenching, tooth area hardness of HRC58-62, equipment are CNC grinding approach, higher precision, very good speak to.

two.transmission fee is substantial: single phase is increased than 96.five%, double phase is increased than 93%, grade 3 is increased than 90%.

3.secure operation, reduced sounds.

4.modest dimensions, light-weight excess weight, long support daily life, higher carrying ability.

five.straightforward to be disassembled and effortless to put in.

Our Organization

HangZhou EPT Group – 1 of the biggest gearbox manufacturer in China – Electromechanical Amenities Co. Ltd

HangZhou EPT Group – one particular of the most significant gearbox manufacturer in China – Electromechanical Products Co., Ltd.is a present business integrating improvement, layout, generation and income,Primary advertising items consist of gearbox motor,h2o pump,building equipment and components,bearings,components and electrical equipment,plastic products,Labour protection equipment.Our firm constantly comply with the procedure notion which is made up of individuals-oriented, innovation as the soul,be geared up for ….

Software region

Certifications

Sales territory

Packing & Shipping and delivery

|

Packaging |

|

|

Measurement |

500 (L) * five hundred (W) * four hundred (D) |

|

Excess weight |

1.2 T |

|

Packaging Specifics |

The standard package is picket box(Size: L*W*H). If export to european nations,the wood box will be fumigated.If container is way too tigher,we will use pe film for packing or pack it in accordance to buyers particular request. |

|

Packaging |

|

|

Dimensions |

five hundred (L) * five hundred (W) * 400 (D) |

|

Fat |

1.2 T |

|

Packaging Details |

The normal package deal is wooden box(Dimensions: L*W*H). If export to european nations around the world,the wooden box will be fumigated.If container is as well tigher,we will use pe film for packing or pack it according to buyers particular ask for. |

FAQ

Q1: Are you trading company or manufacturer ?

A: We are a maker in ZheJiang China.welcome to our manufacturing unit to have a visit.

Q2: How we decide on types and technical specs?

A:You can e mail us the sequence name & code (for case in point: WJ sequence worm gearbox) as properly as need information, these kinds of as motor energy, output velocity or ratio, provider aspect or your application…as considerably knowledge as attainable. If you can source some photos or drawings, it is far better.

Q3: How is your price? Can you supply any discount?

A: We will give the greatest cost we can base on your wants and the quantities.

This fall: How lengthy ought to I hold out for the suggestions after I send out the enquiry?

A: Inside of 12 hrs.

Q5: What is your merchandise guarantee period?

A:We offer you a single yr warranty since the vessel departure day remaining China.

Q6: What industries are your gearboxes getting used?

A:Our gearboxes are extensively utilized to metallurgical tools, mining tools, automation products, foodstuff machinery, packaging tools, tobacco tools and so on.

Make contact with us

Cellular: +86-13083988828 we chat # or 0086-571-88220971 (WeChat)

E-mail:hzptcorp (a) gmail.com

Fox:+86-571-88220972

Include:No.789 ShenHua Road, , XiHu District, HangZhou, ZheJiang, China

HangZhou EPT Group – one of the largest gearbox producer in China – Electromechanical Services Co. Ltd.

EPG – a single of the largest transmission factory in China, major goods: worm geared motors, agricultrual gearbox, planetary gear travel, helical,screw, beve gears and spare parts and agricultural components manunfacuter in China /For more details.: Mobile/Whatpp: +8613083988828

Farm wholesaler China how to measure pto shaft for bush hog Self Propelled Wheel Agriculture Pesticide Sprayer with ce certificate top quality low price

We – EPG Group the biggest agricultural gearbox and pto factory in China with five diverse branches. For a lot more information: Cell/whatsapp/telegram/Kakao us at: 0086-13083988828

jeep wrangler travel shaft Our 2002 chevy silverado push shaft merchandise how to take away the pto shaft on an 8n ford tractor is bmw e60 drive shaft popular semi generate shaft exported utilized pto shafts for sale to weasler pto shaft elements the vw sharan push shaft United pto pump coupling States, king kutter slip clutch Germany, Australia, Russia, Spain, Hungary, Zimbabwe, Ukraine, Nigeria, Peru, Brazil, Center and South The united states, Thailand, Pakistan, Indonesia, far more than sixty nations and locations. Our business is located in XiHu HangZhou Zhejiang Province. T

3WPZ-1200G kind self propelled spray increase sprayer

3WPZ-1200G collection of sprayer is suitable for spraying the medicament for the planter of bean, corn, cotton, grain.

Also for lawn,fruiter,vegetable, highway side tree. The ability could be 1200L, the spraying width could be 13.one-16m with 53hp.

Rewards:

•This variety of increase sprayer is a tractor mounted sprayer.

•Wide functioning scope,spraying for bean,cotton,corn etc.

•Wide spraying with to be 16m max.and the operating angle of this tractor sprayer could be modified.

•The capacity of mounted increase sprayer could be adjusted to meet up with distinct require from the person.

| Model | 3WPZ-1200G self-propelled spray increase sprayer | Pump Type | Plunger pump |

| Engine Model | 4L68 (Changchai) turbocharged EPT motor | Pump Model | OS-5200 |

| Power / Velocity | 53 hp 2400r / min | Pump Stress | 0-45kgf/cm² |

| Displacement Amount | China III | Pump Flow | 220-240L / Min |

| Gear | Forward gear 4,reverse gear 1 | Pump Speed | 600-800r / min |

| Drive Manner | Four-wheel push | Tank Capability | 1500L |

| Steering Mode | Hydraulic steering | Spray Height | 0.5-three. m |

| Mixing Approach | Circulating h2o mixing | Nozzle Design | No.3 |

| Folding Method | Hydraulic folding | Spray Angle | 110° |

| Spray Width | 16 m | Nozzle Movement | 1.2L / min |

| Vertical Peak | 1.eight m(customizable) | System Perform Pressure | 0.three-.5Mpa |

| Wheel Track | 1.ninety five-2.6 m(adjustable) | 3 Filtration Technique | Tank inlet, pump inlet, nozzle |

| Operating Efficiency | 21-30 acres / hour | Battery | 12v / 120AH |

| Walking Pace | ≤25Km / h | Front Tire Product | Tractor tires 9.5-24 |

| Overall Dimension | 5800 mm x 2900 mm x 3700 mm | Rear Tire Model | Tractor tires nine.5-24 |

| Weight | 3811Kg | Water Tank | 15L |

Q:Are you a manufacturing facility or trading firm?

A:We are a factory.

Q: How does your manufacturing unit do regarding top quality handle?

A: Quality is precedence. we often say wonderful value to high quality controlling from the quite beginning to the extremely conclude.

Q: Do you have a merchandise accessory?

A: Yes, we have the add-ons of the item.

Q:Can you customise the solution?

A:We can personalize the item.

Q: What’s your payment terms?

A: Payment terms is T/T or L/C,We accept all reasonable payment.

Q: How about delivery time of your machine?

A: The delivery time is in 60 working days. It depending your quantity.

High China Pressure Curved Flexible Drive Spider Jaw Shaft Star Coupling – Supplier Manufacturer wholesaler Factory

For far more information.: Mobile/Whatpp: +8613083988828

specialize in power transmission merchandise,pto shaft, agricultural gearboxes , CATV products, mechanical seal, hydraulic and Pheumatic, and advertising merchandise.EPG Machinery is situated in XiHu Location HangZhou Zhejiang ,China. It is 30km from our factory to HangZhou worldwide airport.

Overview

Rapid Particulars

- Applicable Industries:

-

Production Plant, farms, Building works , Metal Shaft Sleeve coupling

- Area of Origin:Zhejiang, China

- Brand name Identify:

-

OEM

- Item identify:

-

2018 Higher Good quality TS-S flexible jaw coupling

- Brand name:

-

Tanso

- Application:

-

Shaft Connections

- Human body Substance:

-

45# Steel

- Surface area Remedy:

-

Blackening

- Certification:

-

ISO9001:2008

- MOQ:

-

one Established

- Shipping TIME:

-

10-fifteen Days

- PAYMENT Term:

-

T/T

- Color:

-

Black

Offer Ability

- Offer Capacity:

- 5000 Set/Sets per Thirty day period

Packaging & Shipping and delivery

- Packaging Particulars

- regular export packing and wooden scenario

- Port

- XINGANG

-

Direct Time

: -

Amount(Sets) 1 – 500 501 – 5000 >5000 Est. Time(days) 7 15 To be negotiated

On-line Customization

versatile jaw coupling

Merchandise Description

A jaw coupling is a type of general goal electrical power transmission coupling that also can be utilized in motion manage (servo) apps. It is created to transmit torque (by connecting two shafts) while damping technique vibrations and accommodating misalignment, which guards other components from hurt. Jaw couplings are composed of 3 components: two metallic hubs and an elastomer insert referred to as an factor, but commonly referred to as a “spider”. The a few components press suit with each other with a jaw from every single hub equipped alternately with the lobes of the spider. Jaw coupling torque is transmitted via the elastomer lobes in compression.

The elastomer of the spider can be manufactured in various supplies and hardness, which enables the consumer to personalize the coupling to very best provide their software. Considerations for elastomer choice contain ability to dampen vibration, ability to deal with misalignment, operational temperature variety, speed of gear, and chemical circumstances.

Attributes of TS-S adaptable jaw coupling:

one.Double components & double structure for bigger misalignment

two.Damping vibration ,lower noise

3.Spacer struction can prolong doing work life

Item parameters

Organization Information

HangZhou EPT Couplings Co., Ltd. specializes in the investigation and creation of growth coupling sleeve, mechanical drives and mechanical seals. Thanks to our years of knowledge in research and advancement of couplings, and favorable conditions and dominant advantages in study and growth of higher-precision products and mass manufacturing, the company can meet up with customers’ calls for.

The business has passed the certification of ISO9001-2000 Good quality Management System, and realized CAD computer aided design and information management, integrating investigation, growth and production.strives to offer goods of best high quality and preferential rates.

Why Select Us???

1.Substantial good quality product—-Our tenet is “quality first”.Excellent content,specific

manufacturing procedures and rigid quality handle can generate excellent

good quality.

2.Aggressive cost—-We have our very own factory,scientific producing,

immediate-offering.So we can help save the cost and source lower cost.

three.Specialist—– Our professional engineer can response technical

concerns,assist you fix complex problems and support you pick the

most appropriate merchandise according to your requirment.

4.Delivery rapidly —–We are in close proximity to port,and we have professional forwarder.

Merchandise can be despatched out within 3 to 10 functioning times dependent on purchase quantity.

5.Best services—–Answering e-mails or solving inquiries well timed.

Shipping and delivery and update information on time.

Our Solutions

one. The queries about the coupling will be answered inside of 24 hours.

two. Update the procession of production.

three. Our specialist engineer can solution complex queries,assist you solve specialized difficulties and support you choose the most suitable product in accordance to your requirment.

four. Guarantee 12 months: Free replacement of defective merchandise inside 12 months.

Packaging & Transport

|

PACKING |

Internal Packing: Carton, Standard export packing or According to customer’s requirement Outer packing: picket circumstances or According to customer’s prerequisite |

|

SAMPLE TIME |

5–15 days |

|

Generation TIME |

7–35 days or According to customer’s requirement |

|

Shipping CLAUSE |

FOB Tianjin, CFR, CIF, Specific shipping and delivery |

|

PAYMENT Currency |

USD |

|

PAYMENT Techniques |

T/T (thirty% deposit 70%against bl duplicate) L/C MoneyGram Other payment terms we can negotiate |

FAQ

Q1: Are you investing organization or producer ?

A: We are manufacturing facility.

Q2:Do you give samples ? is it free or added ?

A: : Sure, we could supply the sample but not for free of charge.Actually we have a really very good cost principle, when you make the bulk get then expense of sample will be return to you.

Q3: How prolonged is your delivery time?

A: Normally it is three-10 days if the goods are in inventory. or it is seven-twenty five days if the products are not in stock, it is in accordance to quantity.

This autumn:How extended is your guarantee?

A: Our Guarantee is twelve month.

Q5 :Do you have inspection methods for coupling ?

A:a hundred% self-inspection before packing

Q6. What’s your payment?

1) a hundred% T/T

2) thirty% in progress, other individuals prior to shipment.

three) L/C

Q7:Can I have a check out to your manufacturing unit ahead of the buy?

A: Positive,welcome to pay a visit to our manufacturing facility.

Right here is our manufacturing unit tackle: Nancang Road, Botou, Hebei Province.

EPG – one of the most significant transmission manufacturing facility in China, principal goods: worm geared motors, agricultrual gearbox, planetary equipment generate, helical,screw, beve gears and spare components and agricultural components manunfacuter in ChinaFor much more info.: Cellular/Whatpp: +8613083988828

Wholesale wholesaler China double cv driveshaft Pto Drive Shaft for Farming Equipment Machine Parts with ce certificate top quality low price

We – EPG Group the greatest agricultural gearbox and pto factory in China with 5 distinct branches. For far more specifics: Cell/whatsapp/telegram/Kakao us at: 0086-13083988828

bush hog pto shaft parts The universal joint pto shaft organization pto pump coupling covering 2005 jeep liberty front push shaft 88,000 pto shaft hazards sq. vauxhall astra drive shaft meters, suburban generate shaft has pto travel shaft not functioning sophisticated pto shaft edmonton equipment damaged 540 pto shaft and strong specialized strength, this sort of as the numerical handle equipment equipment and machining facilities, CAD/CAM technique, industrial robot and so forth. It is our purpose to supply a extensive assortment of top quality merchandise at affordable prices, give the best service for buyers happy and add to our continued advancement.

Wholesale pto drive shaft for Farming Equipment Machine Parts

one. Tubes or Pipes

We have previously got Triangular profile tube and Lemon profile tube for all the collection we provide.

And we have some star tube, splined tube and other profile tubes needed by our clients (for a specific collection). (Remember to discover that our catalog doesnt incorporate all the products we generate)

If you w EPT tubes other than triangular or lemon, remember to supply drawings or pictures.

2.Finish yokes

We have got numerous varieties of fast launch yokes and basic bore yoke. I will recommend the usual kind for your reference.

You can also deliver drawings or photos to us if you can not find your item in our catalog.

three. Basic safety devices or clutches

I will connect the detai EPT of safety units for your reference. We’ve previously have Cost-free wheel (RA), Ratchet torque limiter(SA), Shear bolt torque limiter(SB), 3types of friction torque limiter (FF,FFS,FCS) and overrunning couplers(adapters) (FAS).

four.For any other a lot more EPT specifications with plastic guard, link technique, coloration of portray, bundle, and so forth., remember to come to feel free to enable me know.

Features:

one. We have been specialized in creating, producing drive shaft, steering coupler shaft, universal joints, which have exported to the United states of america, Europe, Australia and many others for years

two. Software to all kinds of common mechanical situation

3. Our items are of large intensity and rigidity.

four. Warmth resist EPT & Acid resistant

5. OEM orders are welcomed

Our manufacturing facility is a leading maker of PTO shaft yoke and universal joint.

We manufacture higher quality PTO yokes for a variety of autos, EPT equipment and gear. All products are constructed with rotating lighter.

We are presently exporting our items during the entire world, particularly to North The united states, South The united states, Europe, and Russia. If you are interested in any merchandise, make sure you do not hesitate to speak to us. We are searching ahead to turning into your suppliers in the near foreseeable future.

07+FF1 China High Quality Competitive Price Pto Cardan Shaft – Supplier Manufacturer wholesaler Factory

For more information.: Mobile/Whatpp: +8613083988828

The lemon tube is suitable for transmissible power of sixteen-35HP, it is the desired choice for large speeds and lower torque transmission. The two-lobe lemon tube grants reduced vibrations up to 2600 rpm with lengths not exceeding 800mm. AC collection with six-lobe tubes (star)Founded in the year 1997, we “EPG” are a dependable and famous Manufacturer of a broad range of Thresher Device, Thresher Gearbox and Chaff Cutters. We are a Proprietor company, which is found in HangZhou. We offer these goods in varied technical specs to achieve the full satisfaction of the clients. More, our powerful logistic help can make sure that these merchandise are sent inside the promised time-frame. Under the supervision of “Mr.Shen” (Proprietor), we have acquired large clientele in our region.Our product range consists of all types of helical gear, spur equipment, bevel gear, equipment rack, worm equipment, sprockets,chains, bearings, pto shaft, agricultural gearboxes.Main merchandise include: manure spreading truck, potato planting/harvesting equipment, disc plough, disc harrow, grass Mower/slasher, corn and wheat thershers, seeder, mouldboard plow, deep subsoiler equipment, rotary tiller, rear blade, fertilizer spreader, merge rice harvester, corn thresher, farm trailer, ridger, trencher, stubble cleaner, earth auger, cultivator and its add-ons: Plow disc blades, harrowing film, plough suggestion and share, cultivator tine, casting elements and many others.

Overview

Quick Details

- Warranty:

-

1.5 a long time

- Relevant Industries:

-

Producing Plant, OEM

- Soon after Guarantee Service:

-

Online support

- Neighborhood Service Location:

-

None, Italy

- Showroom Place:

-

None

- Sort:

-

Shafts

- Area of Origin:Zhejiang, China

- Model Title:

-

OEM

- certification:

-

CE

- Materials:

-

Metal

- Color:

-

Yellow&Black

- Processing of yoke:

-

Forging

- Processing of tube:

-

Chilly drawn

- Design and style:

-

Tailored

- Certification:

-

CE Certification

Supply Capacity

- Offer Ability:

- 10000 Piece/Parts for every Month pto cardan shaft

Packaging & Supply

- Packaging Specifics

- carton/iron crate pto cardan shaft

- Port

- ningbo or shanghai

On the web Customization

Merchandise Information

Merchandise Information