Product Description

Stainless Steel Coupling Gear Rigid Roller Chain Fluid Tyre Grid Jaw Spider HRC Nm Motor Flange Gear Pump Rubber Spline Shaft Flexible Universal Joint Coupling

Product Description

Main products

Coupling refers to a device that connects 2 shafts or shafts and rotating parts, rotates together during the transmission of motion and power, and does not disengage under normal conditions. Sometimes it is also used as a safety device to prevent the connected parts from bearing excessive load, which plays the role of overload protection.

Couplings can be divided into rigid couplings and flexible couplings.

Rigid couplings do not have buffering property and the ability to compensate the relative displacement of 2 axes. It is required that the 2 axes be strictly aligned. However, such couplings are simple in structure, low in manufacturing cost, convenient in assembly and disassembly, and maintenance, which can ensure that the 2 axes are relatively neutral, have large transmission torque, and are widely used. Commonly used are flange coupling, sleeve coupling and jacket coupling.

Flexible coupling can also be divided into flexible coupling without elastic element and flexible coupling with elastic element. The former type only has the ability to compensate the relative displacement of 2 axes, but cannot cushion and reduce vibration. Common types include slider coupling, gear coupling, universal coupling and chain coupling; The latter type contains elastic elements. In addition to the ability to compensate the relative displacement of 2 axes, it also has the functions of buffering and vibration reduction. However, due to the strength of elastic elements, the transmitted torque is generally inferior to that of flexible couplings without elastic elements. Common types include elastic sleeve pin couplings, elastic pin couplings, quincunx couplings, tire type couplings, serpentine spring couplings, spring couplings, etc

Coupling performance

1) Mobility. The movability of the coupling refers to the ability to compensate the relative displacement of 2 rotating components. Factors such as manufacturing and installation errors between connected components, temperature changes during operation and deformation under load all put CHINAMFG requirements for mobility. The movable performance compensates or alleviates the additional load between shafts, bearings, couplings and other components caused by the relative displacement between rotating components.

(2) Buffering. For the occasions where the load is often started or the working load changes, the coupling shall be equipped with elastic elements that play the role of cushioning and vibration reduction to protect the prime mover and the working machine from little or no damage.

(3) Safe, reliable, with sufficient strength and service life.

(4) Simple structure, easy to assemble, disassemble and maintain.

How to select the appropriate coupling type

The following items should be considered when selecting the coupling type.

1. The size and nature of the required transmission torque, the requirements for buffering and damping functions, and whether resonance may occur.

2. The relative displacement of the axes of the 2 shafts is caused by manufacturing and assembly errors, shaft load and thermal expansion deformation, and relative movement between components.

3. Permissible overall dimensions and installation methods, and necessary operating space for assembly, adjustment and maintenance. For large couplings, they should be able to be disassembled without axial movement of the shaft.

In addition, the working environment, service life, lubrication, sealing, economy and other conditions should also be considered, and a suitable coupling type should be selected by referring to the characteristics of various couplings.

If you cannot determine the type, you can contact our professional engineer

Related products

Company Profile

Our Equipments

Main production equipment:

Large lathe, surface grinder, milling machine, gear shaper, spline milling machine, horizontal broaching machine, gear hobbing machine, shaper, slotting machine, bench drilling machine, radial drilling machine, boring machine, band sawing machine, horizontal lathe, end milling machine, crankshaft grinder, CNC milling machine, casting equipment, etc.

Inspection equipment:

Dynamic balance tester, high-speed intelligent carbon and sulfur analyzer, Blochon optical hardness tester, Leeb hardness tester, magnetic yoke flaw detector, special detection, modular fixture (self-made), etc.

Machining equipments

Heat equipment

Our Factory

Application – Photos from our partner customers

Company Profile

Our leading products are mechanical transmission basic parts – couplings, mainly including universal couplings, drum gear couplings, elastic couplings and other 3 categories of more than 30 series of varieties. It is widely used in metallurgical steel rolling, wind power, hydropower, mining, engineering machinery, petrochemical, lifting, paper making, rubber, rail transit, shipbuilding and marine engineering and other industries.

Our factory takes the basic parts of national standards as the benchmark, has more than 40 years of coupling production experience, takes “scientific management, pioneering and innovation, ensuring quality and customer satisfaction” as the quality policy, and aims to continuously provide users with satisfactory products and services. The production is guided by reasonable process, and the ISO9001:2015 quality management system standard is strictly implemented. We adhere to the principle of continuous improvement and innovation of coupling products. In recent years, it has successfully developed 10 national patent products such as SWF cross shaft universal coupling, among which the double cross shaft universal joint has won the national invention patent, SWF cross shaft universal coupling has won the new product award of China’s general mechanical parts coupling industry and the ZHangZhoug Province new product science and technology project.

Our factory has strong technical force, excellent process equipment, complete professional production equipment, perfect detection means, excellent after-sales service, various products and complete specifications. At the same time, we can provide the design and manufacturing of special non-standard products according to the needs of users. Our products sell well at home and abroad, and are trusted by the majority of users. We sincerely welcome friends from all walks of life at home and abroad to visit and negotiate for common development.p

Are there any industry standards or guidelines for designing and using spider couplings?

Yes, there are industry standards and guidelines that provide recommendations for designing, selecting, and using spider couplings in various mechanical systems. These standards help ensure the safe and reliable operation of spider couplings in industrial applications. Some of the relevant standards include:

- AGMA 9002-B15: This American Gear Manufacturers Association (AGMA) standard provides guidelines for the selection and application of flexible couplings, including spider couplings. It covers topics such as coupling types, misalignment, torque capacity, and lubrication.

- ISO 14691: This International Organization for Standardization (ISO) standard specifies methods for testing the torsional stiffness of flexible couplings, including spider couplings. It outlines procedures for determining the dynamic torsional stiffness and related parameters.

- API 671: This American Petroleum Institute (API) standard provides guidelines for special-purpose couplings used in petroleum, chemical, and gas industry services. It covers design, manufacturing, inspection, and testing requirements for couplings, including those with elastomeric elements.

While these standards offer valuable insights, it’s important to note that specific industry requirements and applications may influence the design and selection of spider couplings. Manufacturers, engineers, and designers should also consider factors such as torque, misalignment compensation, environment, and system dynamics when applying these standards to their designs. Adhering to industry standards ensures that spider couplings are properly designed, installed, and used to meet the intended performance and safety criteria.

How do you diagnose and troubleshoot issues related to spider couplings in machinery systems?

Diagnosing and troubleshooting issues with spider couplings requires a systematic approach to identify the root cause of the problem and implement effective solutions. Here are the steps to diagnose and troubleshoot spider coupling-related issues:

- Visual Inspection: Conduct a thorough visual inspection of the coupling, looking for visible signs of wear, damage, or misalignment. Check for cracks, tears, and irregularities in the elastomeric spider.

- Vibration Analysis: Use vibration analysis tools to assess vibration levels during operation. Elevated vibration can indicate issues such as misalignment, wear, or unbalanced loads.

- Performance Monitoring: Monitor the performance of connected machinery or equipment. If there’s a decrease in torque transmission, efficiency, or overall performance, it could be attributed to coupling problems.

- Alignment Check: Ensure proper alignment between shafts connected by the coupling. Misalignment can cause uneven load distribution and lead to coupling wear.

- Temperature Monitoring: Monitor the temperature of the coupling during operation. Abnormal temperature increases could point to excessive friction and wear.

- Inspect Fasteners: Check for loose or worn-out fasteners such as bolts, nuts, and screws that secure the coupling components. Loose fasteners can contribute to misalignment and coupling issues.

- Inspect Lubrication: Check the lubrication of the coupling components. Inadequate or degraded lubrication can lead to increased friction and wear.

- Consider Environmental Factors: Evaluate the operating environment for factors such as temperature variations, humidity, and exposure to chemicals. Environmental conditions can affect coupling performance.

- Review Maintenance Records: Review the maintenance history and records of the coupling and connected equipment. This can provide insights into past issues and potential causes.

Based on the diagnostic results, appropriate troubleshooting steps can be taken. These might include adjusting alignment, replacing damaged components, re-lubricating, or replacing the elastomeric spider. Regular maintenance and prompt troubleshooting are essential to ensure the reliable and efficient operation of machinery systems utilizing spider couplings.

What is a spider coupling and how is it used in mechanical systems?

A spider coupling, also known as a jaw coupling or elastomeric coupling, is a type of flexible coupling used to connect two shafts while accommodating misalignment and transmitting torque between them. It consists of three main components: two hubs and an elastomeric spider or insert that fits between them.

The elastomeric spider is typically made of a flexible and durable material, such as rubber or polyurethane, with a series of lobes or fins that fit into matching grooves on the inner surfaces of the hubs. These lobes allow the spider to flex and absorb misalignments between the connected shafts while transmitting torque.

The spider coupling is used in mechanical systems to:

- Transmit Torque: The primary function of a spider coupling is to transmit torque from one shaft to another. As the shafts rotate, the elastomeric spider deforms slightly, allowing the hubs to move relative to each other while maintaining torque transmission.

- Accommodate Misalignment: Spider couplings can accommodate different types of misalignment, including angular, axial, and parallel misalignments, without causing excessive stress on the connected components. This flexibility helps prevent premature wear and failure.

- Dampen Vibrations: The elastomeric material of the spider acts as a shock absorber, dampening vibrations and reducing the transmission of vibrations between the connected shafts. This can improve overall system performance and reduce wear on components.

- Isolate Shock Loads: In applications with sudden changes in torque or shock loads, the spider coupling can absorb and dampen these shocks, protecting the connected components from damage.

- Reduce Maintenance: Spider couplings require minimal maintenance due to their simple design and absence of lubrication points. This can lead to reduced downtime and maintenance costs in industrial machinery.

- Provide Electric Insulation: Spider couplings can provide electrical isolation between the connected shafts, making them suitable for applications where electrical grounding needs to be minimized.

Spider couplings are commonly used in various machinery and equipment, such as pumps, compressors, conveyors, fans, and industrial machinery. They are particularly well-suited for applications that require flexibility, misalignment compensation, vibration reduction, and ease of maintenance.

editor by CX 2023-11-09

China manufacturer & factory supplier for JWB in Cairo Egypt series Worm Gear Ball Screw Jack With high quality best price & service

We have built up our solution range to react to the vastly various circumstances found in different industrial environments all around the entire world. From large market to precision production, we operate with stop-end users in practically each and every business and have professional solutions which are verified to offer a unique functionality benefit for your application.We also can design and style and make non-regular goods to meet customers’ particular specifications.

Overview

Rapid Particulars

- Applicable Industries:

-

Creating Content Retailers, Production Plant, Machinery Mend Stores, Farms, Design works , Foodstuff & Beverage Retailers

- Ratio:

-

up to thirty

- Mounting Placement:

-

Foot Mounted,flange Mounted

- Gear substance:

-

20CrMnTi

- Housing Material:

-

HT200

- Heat therapy:

-

Normalizing,carburizing,higher-frequency heating,quenching

- Warranty:

-

12 Months

- Bearing:

-

NSK,HRB,ZWZ,C&U,etc

- Certificate:

-

ISO9001:2015,ISO14001:2015

- Color:

-

Blue RWe distribute numerous other items that are not outlined over, but are nevertheless commonly offered. Really feel cost-free to give us a call or ship us an electronic mail. We are constantly prepared to aid.AL5010,gray RAL7040/7031

Offer Ability

- Source Ability:

- 5000 Piece/Parts per Thirty day period

Packaging & Delivery

- Packaging Particulars

- Plywood scenario

- Port

- Ningbo,Shanghai

-

Guide Time

: -

Quantity(Boxes) one – 10 >10 Est. Time(times) 15 To be negotiated

On the web Customization

Functions

First modular style, biomimetic area with owned intellectual residence appropriate.

Adopt German worm hob to process the worm wheel.

Minimal friction, extended lifecycle, high effectiveness.

Diverse drives, motor or other electrical power generate, also can be pushed by hand.

A variety of output kind.

Main used for

Hoist and tranOur goods are selling effectively in Chinese marketplaces and some merchandise bought in intercontinental marketplaces are nicely gained by Chinese and international customers at residence and overseas.sport

Constructing and building

Forest and paper

Metal processing

Agriculture and foods

Housing material | Solid iron/Ductile iron |

Housing hardness | HBS190-240 |

Equipment materials | 20CrMnTi alloy steel |

Area hardness of gears | HRC58°~62 ° |

Equipment core hardness | HRC33~4Slip clutch sort on the rotary tiller, once again slight oozing of grease on the UJ, do not grease the clutch these run dry and must be “slipped” at minimum once a yr to prevent rusting together0 |

Input / Output shaft substance | 42CrMo alloy metal |

Enter / Output shaft hardness | HRC25~30 |

Machining precision of gears | exact grinding, 6~5 Grade |

Lubricating oil | GB L-CKC220-460, Shell Omala220-460 |

Warmth therapy | tempering, cementiting, quenching, etc. |

Performance | ninety eight% |

Noise (MAX) | sixty~68dB |

Temp. increase (MAX) | 40°C |

Temp. increase (Oil)(MAX) | 50°C |

Vibration | ≤20µm |

Backlash | ≤20Arcmin |

Brand name of bearings | China top manufacturer bearing, HRB/LYC/ZWZ/C&U. Or other brand names asked for, SKF, FAG, INA, NSK. |

Brand name of oil seal | NAK — Taiwan or other makes requested |

Q: Are you buying and selling company or maker ?

Q: Are you buying and selling company or maker ?

A: We At any time-Electrical power Team one particular of the greatest transmission suppliers in the planet are manufacturing unit.

Q: How long is your shipping time?

A: Generally it is 5-10 times if the merchandise are in inventory. or it is 15-20 days if the merchandise are not in stock.

Q: Can we purchase 1 personal computer of every single merchandise for top quality screening?

A: Of course, we are happy to accept trial get for quality screening.

Q: What is your phrases of payment ?

A: Payment=1000USD, 30% T/T in advance, harmony ahead of shippment.

If you have other query, freely to contact us,please.

High qualtiy best price GCLD type gear couplings supplier factory manufacturer & exporter in China

Overview

Quick Details

Applicable Industries: :

Manufacturing Plant

Place of Origin:Zhejiang, China Brand Name: :

OEM

Supply Ability

Supply Ability: : 2000 Piece/Pieces per Day

Packaging & Delivery

We’ve built up our product range to respond to the vastly different conditions found in different industrial environments around the world. From heavy industry to precision manufacturing, we work with end-users in almost every industry and have specialist solutions which are proven to offer a distinct performance advantage for your application. Packaging Details: Neutral Packing Port: Shanghai Lead Time : :

| Quantity(Pieces) | 1 – 10 | >10 |

| Est. Time(days) | 10 | To be negotiated |

Online Customization

| Quantity(Pieces) | 1 | >1 |

| Est. Time(days) | 30 | To be negotiated |

Hangzhou Ever-Power Transmission Co., Ltd. (Member of Ever-Power Group ) is a specialist in making all kinds of mechanical transmission and hydraulic transmission like: planetary gearboxes, worm reducers, in-line helical gear speed reducers, parallel shaft helical gear reducers, helical bevel reducers, helical worm gear reducers, agricultural gearboxes, tractor gearboxes, auto gearboxes, PTO shafts, special reIn 2000, EPG took the lead in gaining ISO14001 environment management certificate and thereafter passed the inspection of clean production and recycling economy, winning the title of “Zhejiang Green Enterprise”.ducer & related gear components and other related products, hydraulic cylinder, gear pumps and so on. Furthermore, we can produce customized variators, geared motors, electric motors and other hydraulic products according to customers’ drawings. Our sales value in year 2007 was over Euro 50 Million. We staff over 1500 workers, and have CNC turning machines and CNC work centers. For more details, please check out our machine lists.

Hangzhou Ever-Power Transmission Co., Ltd. (Member of Ever-Power Group ) is a specialist in making all kinds of mechanical transmission and hydraulic transmission like: planetary gearboxes, worm reducers, in-line helical gear speed reducers, parallel shaft helical gear reducers, helical bevel reducers, helical worm gear reducers, agricultural gearboxes, tractor gearboxes, auto gearboxes, PTO shafts, special reIn 2000, EPG took the lead in gaining ISO14001 environment management certificate and thereafter passed the inspection of clean production and recycling economy, winning the title of “Zhejiang Green Enterprise”.ducer & related gear components and other related products, hydraulic cylinder, gear pumps and so on. Furthermore, we can produce customized variators, geared motors, electric motors and other hydraulic products according to customers’ drawings. Our sales value in year 2007 was over Euro 50 Million. We staff over 1500 workers, and have CNC turning machines and CNC work centers. For more details, please check out our machine lists.

GCLD type gear couplings

|

Material |

45#/40Cr/42CrMo |

|

Color |

Any color available |

|

Packaging |

Plywood case |

Advantage of GCLD Electric Motor Shaft Coupling

1. Widely used in various mechanical and hydraulic fields

2. Low-cost maintenance

3. Compensation for axial, radial and angular misalignment

4. Convenient axial plugging assembly

5. Installed horizontally and vertically without using any social tools.

6. Excellent mechanical properties

7. No brittlement at low temperature

8. Good slippery and frictional properties

9. Exellent electrical insulation

Application of GCLD Electric Motor Shaft Coupling

1. Printing machinery / Packing machinery / Wood-working machinery etc large-scale mechanical equipment

2. Replace to KTR products

Best China manufacturer & factory china factory supplier hydraulic drive wheel motor hydraulic gear motor With high quality best price

EPG has set up a complete set of quality management system which is provided with advanced inspection and test equipment.

Overview

Quick Details

- After Warranty Service:

-

Video technicEPG clearly selects as target the constant improvement; it has always been a precursor of new markets and production techniques. We devote more than 6% of our profits, and almost 4% of the EBITDA, to Research and Development. Therefore, we are able to offer to our customers exclusive made-to-measure products.al support

- Slip Clutch PTO Shaft for Compact Tractor Tillers NEW SLIPCLUTCH PTO SHAFT FOR COMPACT TRACTOR TILLERS ROTO TILLERS BUSHHOG RHINO KINGKUTTER,CARONI,MASCHIO,JOHN DEERE, MOST MODELS three different types of PTO in operation: a non shear, shear pin and slip clutch — the last being the most expensive. Implement end of non shear (r) and shear type (l) Non shear: this is a solid yoke to yoke set up and used with the expectation that certain equipment will not encounter any sudden stops. I figure that the finishing mower does not need a shear set up as the blades will slip to a degree being belt driven and my other mower, the flail mower, is extremely forgiving in its design. Local Service Location:

-

Egypt

- Showroom Location:

-

Egypt

- Type:

-

parts

- After-sales Service Provided:

-

Video technical support

Supply Ability

- Supply Ability:

- 3000 Piece/Pieces per Month

Packaging & Delivery

- Packaging Details

- Carton or Plywood case

Online Customization

low price and top quality kawasaki EPG Machinery is located in XiHu Area HangZhou Zhejiang ,China. It is 30km from our factory to HangZhou international airport. hydraulic motor

1. This series of motor are small volume, economical type, which is designed with Spool Valve, which adapt the gerotor gear set design and provide compact volume, high power and low weight.

2. Advanced manufacturing devices for the Gerotor gear set, which provide small volume, high efficiency and long life.

3. Shaft seal can bear high pressure of motor of which can be used in parallel or in series.

4. Advanced construction design, high power and low weight.

5. BMP series is equivalent to Danfoss “OMP” series and Charlynn “H” series, and also can substitute for White, Parker.

TECHNICAL DATA

| TYPE | BMP-50 | BMP-80 | BMP-100 | BMP-125 | BMP-160 | BMP-200 | BMP-250 | BMP-315 | BMP-400 | |

| Displacement(ml/r) | 52.9 | 79.3 | 98.2 | 120.9 | 158.7 | 196.4 | 241.8 | 317.3 | 392.9 | |

| Max.Pressure.Drop(Mpa) | cont. | 14 | 14 | 14 | 14 | 14 | 14 | 11 | 9 | 7 |

| int. | 17.5 | 17.5 | 17.5 | 17.5 | 17.5 | 17.5 | 14 | 11 | 9 | |

| peak. | 20 | 20 | 20 | 20 | 20 | 20 | 16 | 13 | 11 | |

| Max.torque(N.m) | cont. | 89 | 150 | 191 | 235 | 307 | 365 | 378 | 378 | 378 |

| int. | 110 | 185 | 231 | 292 | 376 | 440 | 465 | 465 | 465 | |

| peak. | 130 | 215 | 268 | 336 | 430 | 506 | 537 | 537 | 537 | |

| Speed.Range(cont.)(r/min) | 10-800 | 10-770 | 9-615 | 9-480 | 8-385 | 7-310 | 5-250 | 5-195 | 5-155 | |

| Max.Flow(cont.)(L/min) | 40 | 60 | 60 | 60 | 60 | 60 | 60 | 60 | 60 | |

| Max.Output.Power(cont.)(Kw) | 7 | 10 | 10 | 10 | 10 | 8 | 6 | 5 | 4 | |

| Weight(kg) | 5.6 | 5.7 | 5.9 | 6 | 6.2 | 6.4 | 6.6 | 6.9 | 7.4 | |

More Products

Packaging & Shipping

Company Information

FAQ

Our Services

Contact US

Best China manufacturer & factory high quality K series bevel gear helical bevel gearbox solid shaft output supplier With high quality best price

We offer OEM service.

Overview

Quick Details

- Applicable Industries:

-

Manufacturing Plant

- Material of housing:

-

Castion Iron

- Material of gear:

-

bronze

- Material of bearing:

-

alloy steel

- Mounting Position:

-

Horizontal (foot Mounted)

- Input Form:

-

Mounting Motor

-

Output Form:

SFI M100 PTO AdapterAs a precautionary measure, it is a good idea to purchase a PTO adapter to ensure compatibility with your particular tractor model. -

Solid Shaft Output

- Certificate:

-

ISO9001

- Warranty:

-

1 Year

- Heat treatment:

-

Quenching

- Color:

-

Blue

Packaging & Delivery

-

Lead Time

: -

Quantity(Bags) 1 – 1 2 – 5 >5 Est. Time(days) 20 25 To be negotiated

Online Customization

Product Description

Introduction of K Series Helical-Bevel Gearbox

EPG brand rotocultivator ploughshares in T. line were selected as the Nationwide Rotary Tillage Machinery Industry “Perfect Brand Products” in 2007 by Rotocultivator Branch of China Agricultural Machinery Industry Association.

Series K right angle drive helical bevel helical geared motors offer ratios from 8 : 1 to 160 : 1 in three stages or up to 10,000 : 1 in five stages. Motors are available up to 160kW and output torque capacity up to 50000 Nm. The Series K geared motor is designed with integral cast feet for base or end mounting and can be offered with single or double extended output shafts. Units are also available shaft mounted or with output flanges and are available for mounting horizontally or vertically. The units can also be offered with a bolt on torque reaction bracket and all variants are available either motorised or with an input shaft assembly. Adding to the range of geared motors this product takes advantage of our many years of accumulated design expertise together with the use of high quality materials and components. The end result is a series of speed reducing geared motors offering high load carrying capacities, increased efficiency, quiet running and reliability.Design Features Include: All units are dimensionally interchangeable with other major manufacturers Braked geared motors are available as standard Units are manufactured and assembled from a family of modular kits for distributor friendliness minimising inventory and maximising availability. Motorised units can be fitted with a backstop module and reducer units can be fitted with a backstop and fan. As improvements in design are being made continually this specification is not to be regarded as binding in detail and drawings and capacities are subject to alteration without notice. Certified drawings will be sent on request.

Introduction of K Series Helical-Bevel Gearbox

|

Excellent design |

High modular design, biomimetic surface with owned intellectual property right. |

|

Superior performance |

With the special gear geometry, it gets high torque, efficiency and long life circle. |

|

Compact structure |

Reasonable space design, fit for most working place |

Title goes here.

Introduction of K Series Helical-Bevel Gearbox

Title goes here.

Parameter Table of K Series Helical-Bevel Gearbox

Title goes here.

Dimension structure of K Series Helical-Bevel Gearbox

Company Profie

ZJ DEVO Gear Technology Co. Ltd is located in the city of Xuzhou, ZJ Province of China. We handle the products of power transmission, our lines mainly cover series products in speed reducers, gearboxes , associatedelectricial motors and other power transmission Maintenance This kind of gear reducer is provided with a permanent lubrication, so it does not need any kind of maintenance.accessories. Based on the versatile functions, our products can be utilized in many fields: machines of waste water treatment, dredgers, chemical industry, cranes, metal working mills, conveyors, paper industry, cement industry, cableways and so on. With the excellent quality and reasonable price , our products enjoy a good reputation from customers and the peers all over the world. We always innovate for the purpose of better meeting the new demands of our customers and adapting the new tendency of the industry. Depending on the principles of honestly operating and mutual benefit, We sincerely look forward to cooperating with you.

Packing & Delivery

Application

FAQ

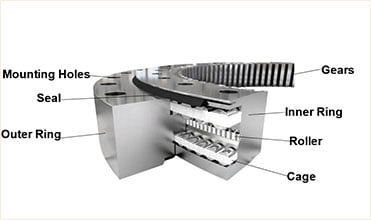

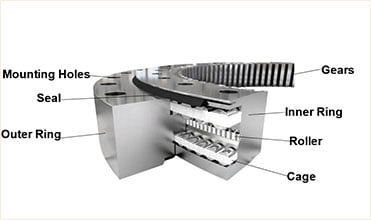

Best China manufacturer & factory china supplier Tower crane slewing bearing 01-3031-00 with external gear large diameter slewing ring bearing With high quality best price

EPG is a professional manufacturer and exporter that is concerned with the design, development and production.

Overview

Quick Details

- Applicable Industries:

-

Building Material Shops, Manufacturing Plant, farms

- Brand Name:

-

OEM

- Brand:

-

syf

- Bore size:

-

200-1300 mm

- Outside Diameter:

-

300-8000mm

- Material:

-

50Mn/42CrMo/Customized

- Module:

-

10

- Teeth:

-

syf

- Dimension:

-

2914*3200*90 mm

- Weight:

-

716 KG

Supply Ability

- Supply Ability:

- 1500 Set/Sets per Month

Packaging & Delivery

- Packaging Details

- 1. Bearing surface is covered with the anti-rust oil first; And then wrapped with the plastic film;

2. And then packed with Kraft paper and professional belts;

3. At last, with wooden box totally at the outer packing to in void the rust or the moist;

4. Packaging can be done according to customer’s requirements.”>HGB Packaging Details:

1. BearinClose up of shear pin which will shear in half if the implement is subject to sufficient resistance Shear pin: the shear pin shaft I use for the chipper/shredder. The driven end yoke is actually two pieces with a shear pin or bolt that holds the two pieces as one during operation. Should the equipment encounter a sudden stop the pin will take the shock and “shear off” preventing any driveline damage. g surface is covered with the anti-rust oil first; And then wrapped with the plastic film;

2. And then packed with Kraft paper and professional belts;

3. At last, with wooden box totally at the outer packing to in void the rust or the moist;

4. Packaging can be done according to customer’s requirements.

- Port

- China any Port

-

Lead Time

: -

Quantity(Bags) 1 – 100 >100 Est. Time(days) 7 To be negotiated

Online Customization

Why Choose Us

Product Description

1,Single row four point contact ball slewing bearing

2,Single row cross roller slewing bearing

3,Double-row ball slewing bearing

4,Three-row roller slewing bearing

5,Roller/Ball Combination Slewing bearing.

Single row four point

contact ball slewing bearing

Single row cross

roller slewing bearing

Double Row

Ball slewing bearing

Three row

roller slewing bearing

Roller/Ball Combination

Slewing bearing

|

Type |

Single row four point contact ball slewing bearing |

|

Rollng elements |

Steel ball / Cylinder Roller |

|

Rollng elements Material |

GCr5/GCr15SiMn/Customized |

|

Bearing Material |

50Mn/42CrMo/42CrMo4V /Customized |

|

Cage Material |

Nylon/ steel /copper |

|

Structure |

taper pin , Mounting holes,Inner ring ,grease fitting,load plug, seals , roller ,spacer balls or separators |

|

Outer diameter |

50-10000mm |

|

Bore size |

50-10000mm |

|

Mounting hole |

Through hole/Tapped hole |

|

Raceway hardness |

55-62HRC |

|

Inner and outer ring modulation hardness |

229-269HB/Customized |

|

Gear type |

No gear ,Internal gear , External gear. |

|

Embellish grease |

EP2 lithium lubricating grease |

|

Certificate |

ABS.BV,DNV,ISO9001,GL |

|

Application area |

Ladle turret,Stacker crane,Bucket wheel machine,Solar heliostat Tracking System,port crane, Cabling machine,tower crane , offshore platform,ferris wheel, Palletizing robot,Rotary metallurgical furnace,can packing machine,Wind blade transporter,shield tunneling machine,tube push bench,excavator |

|

Brand Name |

HGB |

|

Place of Origin |

HangZhou Henan |

|

Warranty |

12 months |

|

Payment term |

T/T is our first choice |

|

Packing details |

1,Filling with anti-rust oil 2.Corved with Plastic paper 3.Corved with kraft paper 4.Corved with Blue tie 5.Put in wooden box |

Product Details

|

Excavator Slewing Bearings are widely used for all brands of excavators, suit for follows models |

|||

|

Slewing Bearings For Hita chi |

EX40-1 EX60-1-2-3-5 EX70-5 EX90 EX100-1-2-3-5 EX110-5 EX120-1-2-3-5 EX130-5 EX200-1-2-3-5 EX210-5 EX220-5 EX270 EX300-1-2-3-5 EX-330 EX330-3 EX350-5 EX400-3 EX400-5 EX470-3 EX870 ZAX60 ZX55-R ZAX70 ZAX80 ZAX110 ZAX120 ZAX130 ZAX200-3-6 ZAX210 ZAX220-5 ZAX230 ZAX240 ZAX240-3 ZAX250-3 ZAX270-3 ZAX450-1 ZAX450-3 ZAX450-5 ZAX750 UH063 UH07-7 UH083 |

||

|

Slewing Bearings For E |

E45 E60 E70B E80 E110 E120B E305 E311 E312B/C E307B/C/D E308 E315 E200 E200B E320 E320B E320C E320D E320L E324D E325/B/C/D E330/B/C E345/B E350 E365 E380 E385 |

||

|

Slewing Bearings For PC |

PC30 PC30-2 PC35 PC40 PC45 PC50 PC50-7 PC55 PC60-5-6-7 PC70 PC75 PC78 PC100-3-5 PC120-3-5-6-6E PC128 PC130-7 PC150-5-7 PC160-7 PC200-1-2-3-4-5-6-7-8 PC210-7 PC220-3-5-6 PC240-8 PC227 PC228 PC270-7 PC300-1-2-3-4-5-6-7 PC350-6-7 PC360-6-7 PC400-3-5-6-7-8 PC450-5-6 PC460-7 PC600-6 PC650-3 PC650 PC800 PC1000 PC1200 PC1250 |

||

|

Slewing Bearings For Sumitomo |

SH50 SH60-1 SH120-1-2/A1/A2/A3/Z3/C3 SH120C3 SH260 SH200 A1/A2/A3/C2/C3/Z3 SH210-5 SH210-A5 SH220-3 SH225 SH240-3-5 SH280 SH350 |

||

|

Slewing Bearings For Hyundai |

R55-5-7 R60-5-7 R70-7 R80-7 R110-7 R130-5-7 R130LC-3-5 R150-7 R170-5 R200-3-5-7 R205-7 R210 R215-7 R220-5-7-9 R225LC-7 R260-7 R280 R290-7 R290LC-3 R290LC-7 R300LC R305LC-7 R320 R330LC R335-7 R375 R360LC-7 R450-7 R450LC R962 |

||

|

Slewing Bearings For Kato |

DH35 DH55 DH60 DH80-7 DH150-5-7 DH200 DH215-7 DH220-2-3-5-7-9 DH258-7 DH280-5 DX60 DX200 DX225 DX260 DX300 DH280 DH290-5 DH300LC-7 DH340 |

||

|

Slewing Bearings For Kobelco |

SK60-3-5 SK100 SK120-1-2-3-5 SK130-8 SK140-8 SK200-6 SK210-6 SK200-6E SK07 SK200-3-5-8 SK210-8 SK220 SK230-6 SK235 SK250-6-8 SK260-8 SK330-6 SK350-8 SK480-8 |

||

|

Slewing Bearings For LIUGONG & For XCMG |

CLG906 CLG907 CLG908 CLG915 CLG915D CLG205C CLG225C CLG220LC CLG225 CLG200 CLG200-3 CLG920D CLG922D CLG925D CLG936LC CLG936D XE60 XE210 XE215 XE150A/B XE230 XE370 210-8 220-8 |

||

|

Slewing Bearings For SANY |

SY65 SY75 SY135 SY185 SY195 SY200 SY205 SY210 SY215-7-8-9 SY235 SY300 SY305 SY310 SY335 SY360 SY365 SY420 |

||

|

Slewing Bearings For Volov |

EC55 EC210 EC210B EC240 EC290 EC360 |

||

|

Slewing Bearings For Liebherr |

R914 R916 R924 R944 |

||

|

Slewing Bearings For Yuchai |

YC15 YC20 YC35 YC60 YC6-5T YC85 YC210-8 YC230-8 YC350 YC400-8 |

||

|

Slewing Bearings For XGMA and For LONKIN |

XG60 XG808 XG815 XG820 XG822 XG823 XG825 LG6060 LG6075 LG6085 LG6090 LG6210 LG6230 LG6225 LG6235 |

||

|

Slewing Bearings For Atlas and For Sunward |

for Atlas3306LC 2006 TC360 2306 SWE50 SWE60 SWE70 SWE80 SWE90 SWE150 |

||

|

More Models for |

For LovolFR85 FR150 FR210 For Bobcat80 For SW210 SW230 For Takeuchi135 175 For CASE CX210B For JCM906D JCM921 JCM922 For EPG75 161 For ZY80 ZY210 For JCB8056 JCB220 For ZW60 ZE80 JV60 SC360 HL60 |

||

Bearing Parts

Steel ball/Roller:carbon-chromium bearing steel GCr15SiMn or GCr15 for rolling Material

Cage: include integral cage, segment cage and spacer-type cage. 20# steel or copper for integral and segment cages, PA 1010 resin or QA110-3-105 albronze for spacer-type cages.

Seals:uses NBR or VITON, few felted wool.

Single row cross roller slewing bearing

Composed of two or three rings. compact structure, light weight, high manufacturing accuracy, small assembly gap and high requirement for installation accuracy. Rollers are 1:1 cross-arranged.

Can be bear axial force, overturning moment and large radial force at the same time,and widely used in lifting transportation, construction machinery and military products.

Three row roller slewing bearing

Three row roller bearing able to bear all kinds of loads at the same time, it is the largest one of the four structural products with large axle and radial dimensions and firm structure. Especially suitable for heavy machinery requiring larger diameter, such as bucket wheel stacker and reclaimer, wheel crane, marine crane, port crane, ladle turret,large tonnage truck crane,heavy machinery and so on.

Single row four point contact ball slewing bearing

Single row four point composed of two seat rings. has compact structure, light weight, and four-point contact between steel ball and arc raceway. It can bear axial force, radial force and overturning moment at the same time. The construction machinery of rotary conveyor, welding manipulator, small and medium-sized crane and excavator can be selected.

More Products

More Products

More Products

More Products

About Us

Wide production workshop and strong production team as a support,ensure the products can be produced by required quality and quantity. andThereby increase the customer benefits.

The above is our production equipment with advanced technology , the stable and longevity bearing produce from these equipment .

We specialize in the production of manufacturing slewing ring bearings or turntable Bearings.The Independent R&D and sales team in HGB , also do our best for special needs;We offer high-precision and high-quality slewing bearings, which are widly used in many fields,such as hoisting and conveying machinery, construction engineering machinery, harbour machinery, wind power generation, radar and missile launchers and so on.

Certificate

FAQ

1.Q: Are you trading company or manufactureOur products is popular exported to the United States, Germany, Australia, Russia, Spain, Hungary, Zimbabwe, Ukraine, Nigeria, Peru, Brazil, Middle and South America, Thailand, Pakistan, Indonesia, more than 60 countries and regions.r ?

A: We are professional slewing bearing manufacturer with 20 years’ experience.

2.Q: How long is your delivery time?

A: Generally it is 4-5 days if the goods are in stock. or it is 45 days if the goods are not in

stock, Also it is according to quantity.

3.Q: Do you provide samples ? is it free or extra ?

A: Yes, we could offer the sample, it is extra.

4.Q: WhThe shaft surface under the oil seal lip is critical to effective sealing. Any lead remaining from the turning process acts like an oil pump and causes leaks. While plunge grinding is the most common method for finishing seal journals, the process does not guarantee acceptable surfaces.at is your terms of payment ?

A: Payment=1000USD, 30% T/T in advance, balance before shipment.

5.Q: Can you provide special customization according to the working conditions?

A: Sure, we can design and produce the slewing bearings for different working conditions.

6.Q: How about your guarantee?

A: We provide lifelong after-sales technical service.

Contact Us

Wechat/Whatsapp: +86 13083988828

Skype: +86 13083988828

Company Name: HangZhou EPG – One of the bigggest transmission manufacturer in China – Ever-Power Transmission Bearing Technology Co., Ltd

Office Address: Room B8F, Block B, shenhua road 789 – jianqiaogongshe International, XiHu District, HangZhou City,China

Phone: +86 13083988828

Factory Address: Bearing zone in XiHu County, HangZhou City, China

China best quality low sales price for high quality low initial co EPT high ratios high output torque vertical mounted cycloidal gear reducer supplier Factory Manufacturer and Supplier -from Pto-shaft.com

EPG is prepared to cooperate sincerely and develop generally with close friends!

Overview

Quick Specifics

- Applicable Industries:

-

EPT Plant

- Coloration:

-

Blue

- Software:

-

Equipment Resource

- Bearing:

-

N EPT Bearing

- Certification:

-

ISO9001

- Enter Kind:

-

IEC Flange

- Mounting Placement:

-

Horizontal (foot Mounted)

- Brand name:

-

DEVO

- Enter/output shaft:

-

Heat Treated

- Content:

-

Metal

- EPT Nation:

-

ZJ. China. ZJ. China (Mainland)

Packaging & Supply

-

Direct Time

: -

Quantity(Baggage) one – 1 two – 5 >5 Est. Time(times) two ten To be negotiated

On the web Customization

Solution Description

Cycloidal equipment equipment box is a basic principle adopted K-H-V Planetary Equipment considerably less progressive gear. Its transmission approach as follows : enter shaft equipped with a one hundred eighty-degree dislocation of the double eccentric sets. replaced with two eccentric turn as a roller bearing arm. the development of H-. two cycloid round gap at the heart shall uplink Eccentric Roller Bearings arm. which cycloidal gear needle round and meshing section. comprising a distinction of the enamel meshing with the gearbox.

|

Variety |

cycloidal pace equipment box |

||

|

Standard voltage and frequency |

380V&50HZ |

||

|

Electricity |

.twenty five-90KW |

||

Major Features

All planetary cycloidal gear box rotating unit can be divided into 3 components:input component.deceleration portion and output part.

1.Higher pace ratio and high efficiency one phase transmission. can achieve one:87 deceleration ratio. effectiveness in far more than ninety%. if the use of multi-phase transmission. deceleration ratio is higher.

2.Due to the compact composition and little volume. the enter shaft and output shaft are on the identical axis line. so that the product can get the smalle EPT measurement.

three.The minimal cycloidal pin tooth with stable operating sound have several meshing enamel. big overlap coefficient and the mechanism of mechanical equilibrium. so that the vibration and sound are limited to a bare minimum diploma.

four.Reputable use. lengthy life due to the fact the main areas employing large carbon chromium steel content. right after quenching therapy (HRC58~62) to get high power. and. part of the transmission speak to employing rolling friction. so lengthy life.

Associated Merchandise

Our Business

Certifications

Pac ept & Supply

Make contact with us

EPG – As one of the largest equipment transmission and agricultural element and equipment manufacturing facility in China, we will offer your higher top quality products with cheapest cost. We update new goods month-to-month from pto-shaft.com

high factory Wholesale Suppliers Online quality R series horizontal gear reducer RF helical gear hard tooth surface reducer vertical gear box supplier

EPG was awarded with “well-known merchandise of Zhejiang Province” and “well-known brand of Zhejiang Province”.

Overview

Swift Particulars

- Relevant Industries:

-

Manufacturing Plant

- Colour:

-

Customer Request

- Packing:

-

PLYWOOD

- Output Kind:

-

Flange Output

- Warranty:

-

12 Months

- Substance:

-

Forged Iron

- Mounting Situation:

-

Horizontal (foot Mounted)

- Certification:

-

ISO9001

- Voltage:

-

3Phase220/380

- Motor:

-

AC motor

Packaging & Shipping and delivery

-

Lead Time

: -

Amount(Baggage) 1 – 1 2 – five >5 Est. Time(times) seven 15 To be negotiated

On the internet Customization

Product Description

Helical gear reducer is a novel reduction gear. R series bevel equipment reducer, with tiny quantity, gentle excess weight, high bearing capability, large effectiveness, lengthy provider lifestyle ,easy installation, equipped with a vast selection of motor electricity, transmission ratio classification fine functions. Can be broadly used in all industries to gradual down the tools.

Comprehensive Photographs

|

Make sure you observe that this value does not consist of motor, you should make contact with us if you require motor, and please explain to us your technical specs of reducer |

||||||||

Dimension Data

Relevant Goods

Company

OUR Firm

We are a company in ZJ Province, China. Our firm owns the capacity of manufacturing, processing, planning and R&D. We welcome your go to.

We handle the items of power transmission, our traces mostly cover sequence merchandise in speed reducers, gearboxes , connected electricial motors and other power transmission accessories. Dependent on the versatile capabilities, our items can be used in several fields: devices of squander drinking water remedy, dredgers, chemical industry, cranes, metal operating mills, conveyors, paper sector, cement industry, cableways and so on.With the exceptional high quality and affordable price , our items take pleasure in a excellent status from customers and the friends all more than the world.

Our costs are always aggressive. If the customer can location a huge get, we definitely will permit low cost.

Packing & Supply

FAQ

Q1: Are you a investing organization or a maker ?

A: We are a company in ZJ Province, China. Our firm owns

the capacity of production, processing, developing and R&D. We welcome your go to.

Q2: How we decide on versions and requirements?

A: In accordance to the certain specifics of the requires from the component of enquiry,

we will advocate the products’ versions on synthesizing the elements of

discipline of goods utilization, electricity, torque arm and ratio…

Q3: How is your value? Can you offer any low cost?

A: Our charges are constantly competitive. If the buyer can spot a large get,

we surely will allow discount.

Q4: How prolonged need to I wait for the opinions following I send out the enquiry?

A: We will reply as shortly as attainable, 12 hrs at most.

Q5: What is your product guarantee time period?

A: We have the certifications of ISO9001,CE, SGS.

Q6: What industries are your gearboxes being utilised?

A: Our gearboxes are broadly used to metallurgical tools, mining

gear, automation tools, foods machinery, packaging tools,

tobacco equipment and so on.

Stroke China 800mm worm gear SWL15 worm elevator lead screw jack hand screw reducer – Supplier Manufacturer wholesaler Factory

For more information.: Mobile/Whatpp: +8613083988828

EPG is a skilled company and exporter that is anxious with the design, growth and production.Our items are marketing properly in Chinese markets and some products offered in intercontinental marketplaces are effectively obtained by Chinese and overseas consumers at residence and abroad.

Overview

Fast Particulars

- Relevant Industries:

-

Manufacturing Plant

- Brand name Name:

-

OEM

- Item NO:

-

SYF

- Application:

-

Lifting Transpor

- Certification:

-

ISO 9001

- Housing Materials:

-

Solid Iron HT200

- Output Sort:

-

Shaft/Flange Output

- Lifting pace:

-

.044-two.592m/min

- Worm velocity:

-

fifty-1800rpm

- Mounting Situation:

-

Foot Mounted. Flange Mounted

- Material:

-

Cooper Wheel

Packaging & Supply

-

Direct Time

: -

Amount(Sets) 1 – three four – 5 >5 Est. Time(days) 5 10 To be negotiated

Online Customization

Solution Description

SWL Worm Equipment Screw Jack

SWL series worm wheel screw elevator is widely applied in idustries such as machinery. meallurgy, design, and hydraulie equipment, and has a lot of functions this kind of as lfting and pushing and turming with the support of acessories or altering peak and placement.

This collection worm screw elevator is 1 product of simple hoisting components and has quite a few features of compact framework, small quantity, mild fat, wide push sources, low noise, higher reliabilit, and prolonged lifespan. In addition, they are effortless to be mounted,versatile in use and appreciate multiple capabilities.

This sequence, driven by motor or other power or manually, can be used each solitary and merged with other people to precisely management the adjustment of height of lfting or pushing by certain packages. For there are several structures and mounting situation, the lfting height can be modified to the consumers rquirements.

|

SWL 2.five M-one A-Ⅱ-five hundred FZ |

||||||||||||||

|

SWL |

2.5 |

M |

one |

A |

Ⅱ |

five hundred |

FZ |

|||||||

|

worm equipment screw jack |

bearing ability(25kN) |

Ratio Code |

structural type code |

structure |

assembly sort |

Screw stroke(mm) |

Defense form code |

|||||||

SWL Worm Equipment Screw Jack Mounting Proportions

Notice:

1. The allowable electricity is a parameter below the situation that the ambient temperature is 20℃ and the working duration rate is 20% for every hour.The complete effectiveness is the parameter below the situation of grease lubrication.3. The allowable torque, power and speed are different when lifting diverse loads, and the electrical power of different starting period is different4. For the elevate with double guide sleeve, the screw can bear lateral power as effectively as axial pressure.The radial pressure that the worm shaft extension is permitted to bear is permitted to install equipment, sprocket or pulley.six. Seek the advice of the company for the earlier mentioned information.seven. It can be self-locked at rest.

SWL Worm Equipment Screw Jack Features:

1. Compact structure, little quantity and hassle-free set up

two. High reliability and lengthy life.

3. It has many functions, this kind of as lifting, descending, pushing and flipping with auxiliary areas.

four. It can be used by itself or in mixture.

five.The electrical power source is extensive. It can be pushed immediately by motor or other energy or manually.

ninety four Copper Worm Wheel

ninety four Copper Worm Wheel with Higher Put on Resistance.

High Top quality SHELL Materials

The box physique which is cleaned by professional screening and washing products to ensure that the inner cavity of the box body is cleaner without having iron filings.

Our Firm

HANGZHOU At any time-Electrical power Team, A single OF THE Most significant GEARBOX Manufacturing facility IN CHINA, ELECTROMECHANICAL Products Provide STATION

Our business is located in the metropolis of HangZhou, ZheJiang Province of China.

We manage the goods of electricity transmission, our traces mostly go over series items in speed gearboxes, gearboxes , associated electricial motors and other energy transmission equipment. Primarily based on the functional functions, our goods can be utilized in a lot of fields: machines of squander drinking water therapy, dredgers, chemical sector, cranes, metal functioning mills, conveyors, paper sector, cement business, cableways and so on.With the superb top quality and realistic price , our products appreciate a good status from buyers and the friends all more than the entire world.

Moreover, the R&D expense are yearly rising for the purpose of better meeting the new calls for of our customers and adapting the new tendency of the market.

Depending on the rules of actually functioning and mutual reward, We sincerely seem ahead to cooperating with you.

Application location

SWL series worm and screw elevators are commonly employed in machinery, metallurgy, development, drinking water conservancy products and other industries. They have the functions of lifting, descending, advancing by auxiliary parts, turning over and other height adjustment capabilities.

Packing&Transportion

PACKING AND TRANSPORTION

●Packaging: In buy to ensure the integrity of item visual appeal, we will choose cartons, picket pallets and wooden pallets in accordance to client wants.

●Delivery time: Each and every gearbox is manufactured and examined in accordance with stringent and mounted processes to make sure that the top quality is correct prior to leaving the factory and delivery on time.

●Transportation method: We will choose the most ideal mode of transportation for our buyers according to the excess weight and size of the products. We can also decide on the mode of transportation according to the needs of our clients.

●Receiving and after-sales provider: Following getting the items, please verify whether or not they are in great problem. We will provide clients with ideal soon after-revenue support.

FAQ

Q1: Are you a buying and selling firm or a manufacturer ?

A: We are a maker in ZheJiang Province, China. Our company owns the potential of producing, processing,creating and R&D. We welcome your pay a visit to.

Q2: How we choose versions and specifications?

A: According to the particular information of the needs from the part of enquiry, we will suggest the products’ versions upon synthesizing the aspects of subject of products utilization, energy, torque arm and ratio…

Q3: How is your price? Can you provide any price reduction?

A: Our charges are constantly competitive. If the client can location a big get, we surely will allow discount.

Q4: How extended should I wait for the suggestions right after I deliver the enquiry?

A4: We will reply the enquiries with out any hold off, twelve hrs at most.

Q5: What is your merchandise guarantee period of time?

A: We have the certifications of ISO99001,CE, SGS.

Q6: What industries are your gearboxes getting utilised?

A: Our gearboxes are commonly applied to metallurgical products, mining products, automation products, foodstuff equipment, packaging products, tobacco equipment and so on.

EPG – one particular of the most significant transmission factory in China, main goods: worm geared motors, agricultrual gearbox, planetary equipment push, helical,screw, beve gears and spare components and agricultural areas manunfacuter in ChinaFor far more information.: Mobile/Whatpp: +8613083988828

Swing China Drive Worm Gear Box, worm speed reducer, worm reducer – Supplier Manufacturer wholesaler Factory

For more information.: Cell/Whatpp: +8613083988828

The EP Line PTO generate shafts are recognizable since of the EP Line patented coupling system and the flexible cone. The PTO generate shafts are distinguished by way of person-friendliness, compactness and attractive layout.Remember to speak to us nowadays with your enquiry. Our merchandise selection also addresses locking assemblies (clamping elements/locking unit), taper bushes, QD bushes, bolt-on hubs, pto shaft, agricultural gearboxes,torque limiters, shaft collars, motor bases and motor slides, chain detachers, chain guides, universal joint, rod finishes and yokes. Adhering to “Survival by Top quality, Advancement by Technology & Credit”, The organization will consistently enhance item efficiency to meet the increasing customer specifications in the rigorous style of work.

Overview

Quick Specifics

- Applicable Industries:

-

OEM

- Brand Title:

-

OEM

- Output Torque:

-

–

- Enter Pace:

-

–

- Output Velocity:

-

–

Online Customization

Merchandise Description

|

At any time-electricity expert in producing all varieties of mechanical transmission and hydraulic transmission like: planetary gearboxes, worm gearboxes, in-line helical gear velocity gearboxes, parallel shaft helical equipment gearboxes, helical bevel gearboxes, helical worm equipment gearboxes, agricultural gearboxes, tractor gearboxes, vehicle gearboxes, pto generate shafts, particular gearbox & relevant gear parts and other connected goods, sprockets, hydraulic system, vaccum pumps, fluid coupling, equipment racks, chains, timing pulleys, udl pace variators, v pulleys, hydraulic cylinder, equipment pumps, screw air compressors, shaft collars minimal backlash worm gearboxes and so on. additionally, we can create customized variators, geared motors, electric motors and other hydraulic merchandise in accordance to customers’ drawings.

|

Swing travel worm gear box

worm gearbox, worm gearbox, worm velocity gearbox

| Application |

| Higher area functioning motor vehicle |

| MAX Enter |

| 3,600 rpm |

| MAX HORSE Electricity |

| 7ps at three,600rpm |

| MAX STATIC TORQUE |

| 3,600in.Lbs |

….

Packaging & Shipping and delivery

Our Providers

Also I would like to get this chance to give a short introduction of our Ever-Power firm:

Our organization is a famous producer of agriculture gearbox,worm reduce gearbox, PTO shafts, Sprockets ,rollar chains, bevel equipment, pulleys and racks in china.

We have exported a lot of items to our customers all over the globe, we have long-time knowledge and sturdy engineering assist.

Some of our buyer :

Italy: COMER,GB GEABOX ,SATI, CHIARAVALLI, AMA , Brevini

Germany: SILOKING ,GKN ,KTS

France: Itfran, Sedies

Brazil: AEMCO ,STU

Usa: John Deere , BLOUNT, Weasler, Agco, Omni Gear, WOODS

Canada: JAY-LOR , CANIMEX ,RingBall

……

-Ø Our Company with more than twelve year’s background and 1000 employees and 20 revenue.

-Ø With in excess of one hundred Million USD sales in 2017

-Ø With advance equipment equipments

-Ø With massive operate capability and high good quality management, ISO certified.

……

you also can check our web site to know for far more particulars, if you require our products catalogue, you should contact with us.

Firm Info

Material available |

Floor therapy |

Warmth treatment method |

|

Minimal carbon steel, C45, 20CrMnTi, 42CrMo, 40Cr, stainless metal. Can be adapted regarding client specifications. |

Blacking, galvanization, chroming, electrophoresis, coloration painting, … |

Large frequency quenching warmth therapy, hardened tooth, carbonizing, nitride, … |

EPG – one of the greatest transmission manufacturing unit in China, principal products: worm geared motors, agricultrual gearbox, planetary gear generate, helical,screw, beve gears and spare components and agricultural areas manunfacuter in China /For a lot more info.: Cell/Whatpp: +8613083988828